Bottom price 1.3343 Steel - HeRui Factory Supply Good Quality Nickel Alloy Inconel 718 Kovar Invar 36 Bar Rods – Herui Detail:

- Place of Origin:

-

Jiangsu, China

- Type:

-

Nickel Bar

- Application:

-

Electromagnet pole head

- Grade:

-

FeCo50V2

- Ni (Min):

-

49% Co and 2% V

- Resistance (μΩ.m):

-

41mm2/m

- Powder Or Not:

-

Not Powder

- Ultimate Strength (≥ MPa):

-

1340

- Elongation (≥ %):

-

9

- Model Number:

-

fe cobalt vanadium alloy

- Brand Name:

-

HeRui

- Product name:

-

Nickel Alloy Inconel 718 Kovar Invar 36 Bar Rods

- Standard:

-

ASTM A801

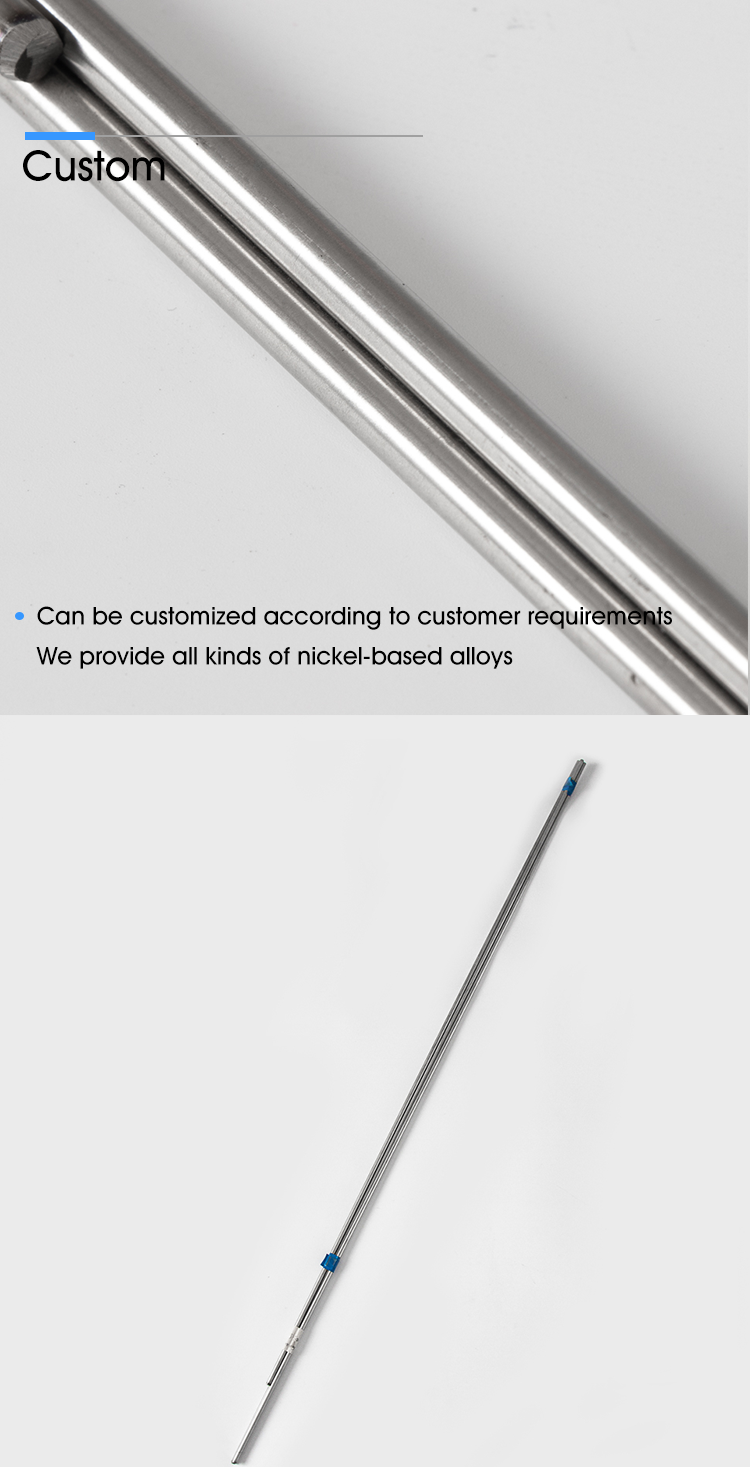

- Surface:

-

Bright

- Delivery Time:

-

30 Days

- Shape:

-

Bar, Plate

- Size:

-

Customized

|

Forms of supply

|

||||

|

ROD

|

Dia.20 to180mm, Length2000mm,Max

|

Surface Finish: Black, De-scaling & Ground Surface

|

||

|

STRIP/SHEET

|

T0.1 to 3.0mm, width300mm,Max

|

Temper Name : Hard / Annealed

|

||

|

PLATE

|

T3.0 to 40.0mm, Width1000mm,Max

|

Surface Finish: Black / Bright

|

||

|

Chemical Composition,%

|

||||||||||||||||||

|

C Max

|

Mn Max

|

Si Max

|

P Max

|

S Max

|

Cr Max

|

Ni Max

|

Co

|

V

|

Fe

|

|||||||||

|

0.025

|

0.15

|

0.15

|

0.015

|

0.01

|

0.15

|

0.25

|

47.5-49.5

|

1.75-2.10

|

Bal.

|

|||||||||

|

DC Magnetic Properties

|

||||||||||

|

Forms

|

Magnetic induction at different magnetic field B,≥(T)

|

Coercivity Hc,≤(A/m)

|

||||||||

|

B800

|

B800

|

B800

|

B800

|

|||||||

|

Cold-Rolling Strip

|

2.00

|

2.00

|

2.00

|

2.00

|

128

|

|||||

|

Forgings ,Bar

|

1.50

|

1.50

|

1.50

|

1.50

|

144

|

|||||

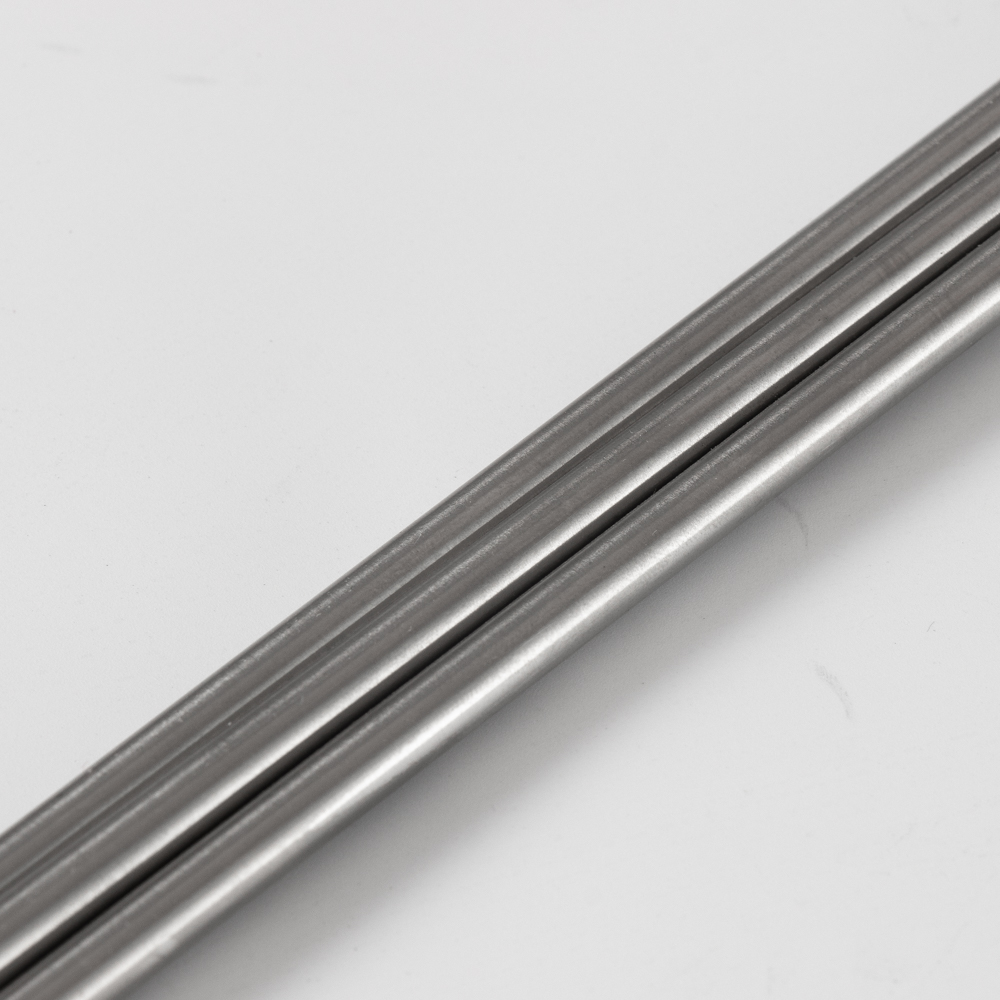

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, believe in the 1st and management the advanced" for Bottom price 1.3343 Steel - HeRui Factory Supply Good Quality Nickel Alloy Inconel 718 Kovar Invar 36 Bar Rods – Herui, The product will supply to all over the world, such as: Indonesia, Bogota, America, With high quality, reasonable price, on-time delivery and customized & personalized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.

-

Best Price for Capillary Tube Air Conditioner -...

-

Manufactur standard Uns N09925 - No magnetic c...

-

New Delivery for Monel Alloy 400 - Electrical ...

-

Wholesale Discount Hss Tool - Non-magnetic pip...

-

Top Suppliers Anti Magnetic Stainless Steel - ...

-

High reputation Copper Nickel Wire - API No ma...