Cheapest Factory Non Magnetic Steel Wiki - High speed steel M2 flat steel – Herui Detail:

Video

Flat steel is rolled with negative deviation, but delivered by actual weight, which increases the utilisation rate by 1 to 5 percentage points compared to steel plates.

Flat steel can be produced in fixed thickness, width and length according to user requirements, which reduces cutting for users and saves processes, reduces the consumption of labour and materials, and also reduces the processing loss of raw materials, saving time, effort and material. The products have been professionally used in steel manufacturing, machinery manufacturing, automotive industry, mining machinery, lifting machinery and other industrial materials.

M2 round bar is a representative steel grade of tungsten-molybdenum general-purpose high-speed steel, with better toughness and wear resistance than W18Cr4V, and comparable hardness, red hardness and high-temperature hardness. It can be used for the manufacture of various tools that are subject to high impact forces, large general tools and thermoplastic forming tools, as well as for parts that wear under high loads and cold work moulds.

M2 is a molybdenum-based high-speed steel with the advantages of low carbide inhomogeneity and high toughness. It is easy to overheat, so the quenching heating temperature should be strictly controlled, and the heat treatment protection requirements are more stringent. Due to its hardness and good wear resistance, it is mostly used in the manufacture of cutting tools for difficult-to-cut materials. M2 HSS has a greater tendency to carbide, so the heat treatment protection requirements are more stringent, suitable for vibration and impact load bearing moulds.

Main applications

Cold forging dies, fine blanking dies, powder pressing dies, etc., shearing machine dies, plastic dies with added glass fibre, etc. Dies suitable for vibration and impact loads: deep drawing dies, punching dies. Metal cutting saw blades, cold heading and extrusion tools, etc.

Description

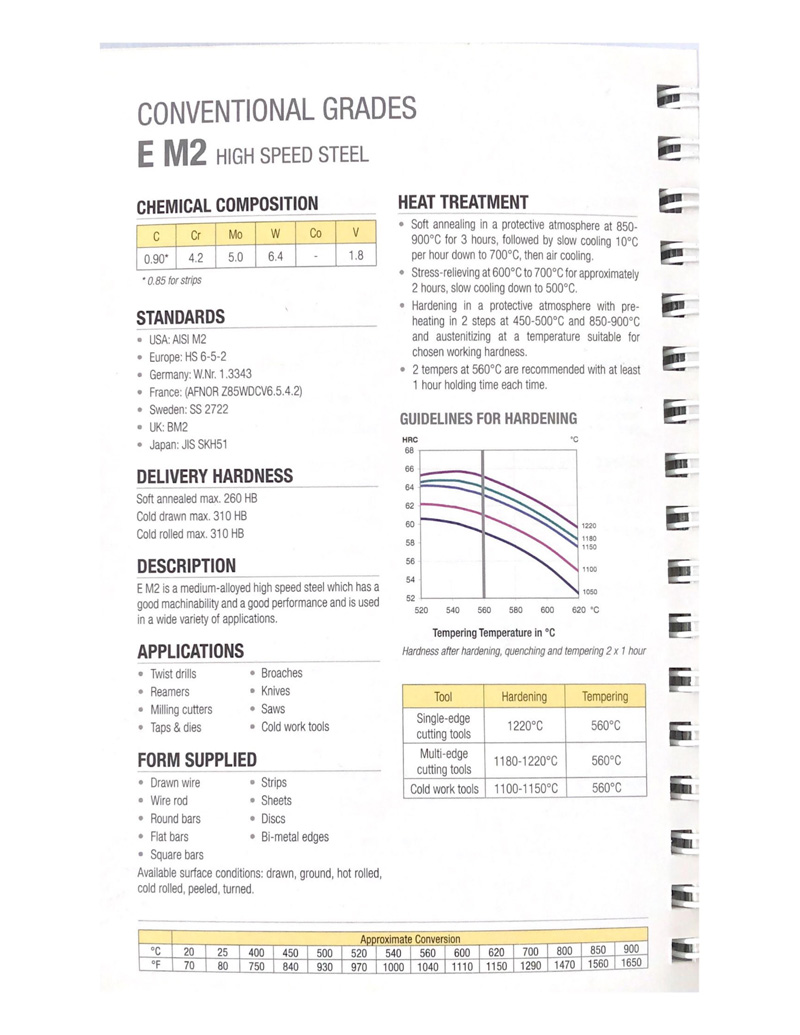

Chemical composition

Carbon C: 0.80-0.90 (Allowable deviation: ±0.01)

Silicon Si: 0.20~0.45 (Allowable deviation: ±0.05)

Manganese Mn:0.15~0.40(Allowable deviation:+0.04)

Sulfur S: ≤0.030

Phosphorus P:≤0.030

Chromium Cr:3.80~4.40(Allowable deviation:±0.05)

Nickel Ni: residual content ≤0.30

Copper Cu: residual content ≤0.25

Vanadium V:1.75~2.20(Allowable deviation:±0.05)

Molybdenum Mo:4.50~5.50(Allowable deviation: size≤6,±0.05;size>6,±0.10)

Tungsten W :5.50~6.75(Allowable deviation: size≤10,±0.10;size>10,±0.20)

Product detail pictures:

Related Product Guide:

We will devote ourselves to giving our esteemed buyers using the most enthusiastically thoughtful services for Cheapest Factory Non Magnetic Steel Wiki - High speed steel M2 flat steel – Herui, The product will supply to all over the world, such as: South Africa, UK, Kazakhstan, We firmly think that we have the full capability to give you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

-

PriceList for High Speed Steel Cutting Tools -...

-

Personlized Products Inconel 925 - Factoey pri...

-

Manufacturing Companies for Austenitic Stainles...

-

2021 High quality M2 Tool Steel Supplier - Fac...

-

Good quality Incoloy Alloys - High quality oil...

-

New Arrival China Controlled Expansion Alloys -...