China Cheap price Machining Monel 400 - Inconel X-750 – Herui Detail:

Description

Inconel X-750 (UNS N07750 / W. Nr. 2.4669 / GH4145 / NiCr15Fe7TiAl) is a precipitation-hardenable nickel-chromium alloy used for its corrosion and oxidation resistance and high strength at temperatures to 1300°F. Although much of the effect of precipitation hardening is lost with increasing temperature over 1300°F, heat-treated material has useful strength up to 1800°F. This kind of alloy also has excellent properties down to cryogenic temperatures.

Typical chemical composition

| Nickel (plus Cobalt) | 70.00 min. |

| Chromium | 14.0-17.0 |

| Iron | 5.0-9.0 |

| Titanium | 2.25-2.75 |

| Aluminum | 0.40-1.00 |

| Niobium (plus Tantalum) | 0.70-1.20 |

| Manganese | 1.00 max. |

| Silicon | 0.50 max. |

| Sulfur | 0.01 max. |

| Copper | 0.50 max. |

| Carbon | 0.08 max. |

| Cobalt | 1.00 max |

Application

Oil and gas production

Gas turbine engines

Nuclear engineering

Equal grade

GH4145, UNS N07750, Alloy X-750, W. Nr. 2.4669

Forms available

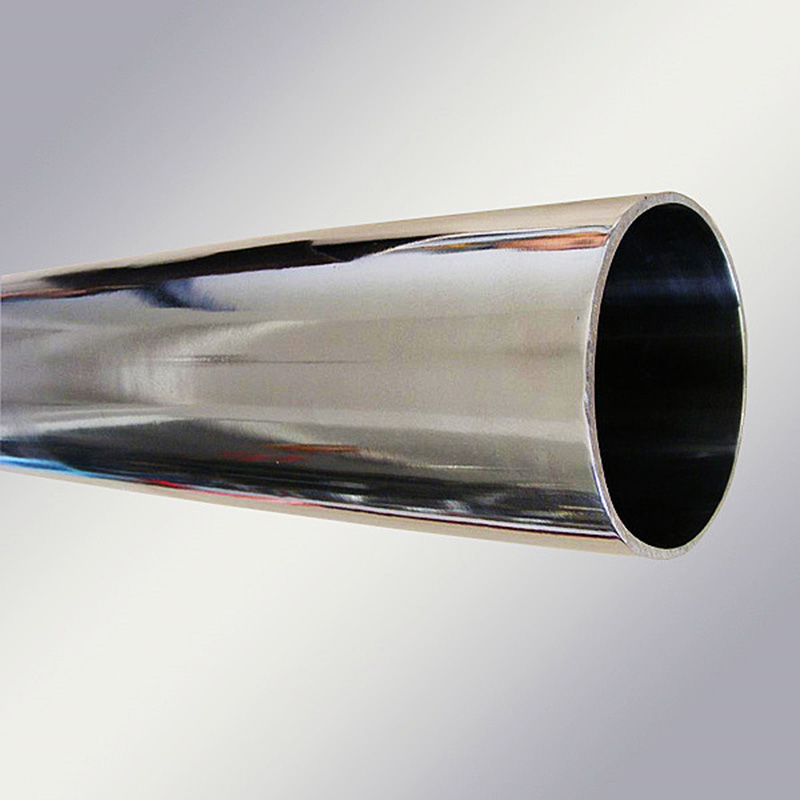

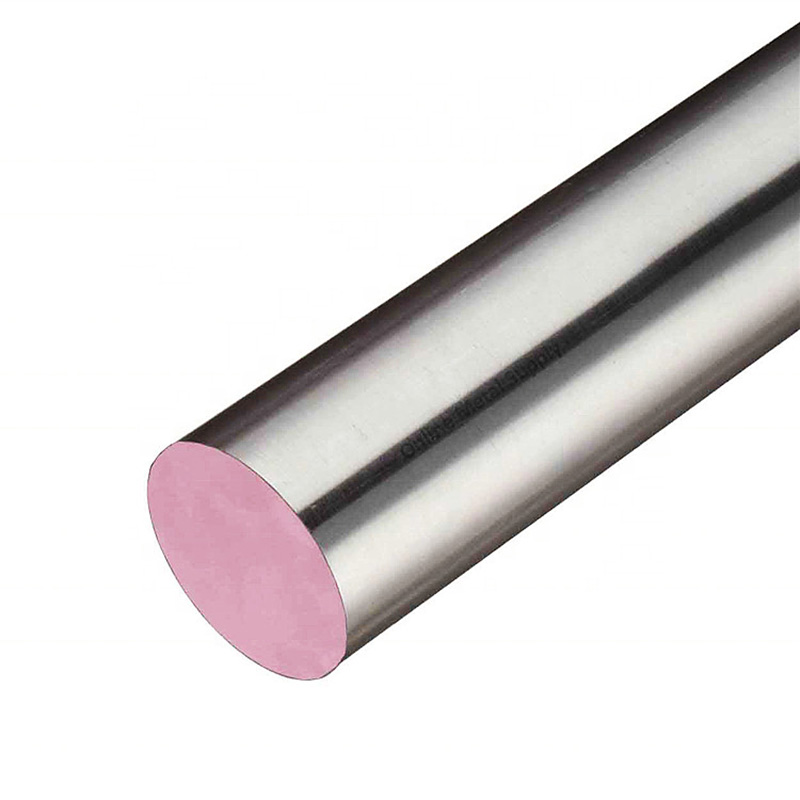

Plate, sheet, strip, wire, rod, bar, forging

Product detail pictures:

Related Product Guide:

We consistently execute our spirit of ''Innovation bringing progress, Highly-quality ensuring subsistence, Administration advertising and marketing gain, Credit history attracting buyers for China Cheap price Machining Monel 400 - Inconel X-750 – Herui, The product will supply to all over the world, such as: Sacramento, Ghana, Slovakia, Business philosophy: Take the customer as the Center, take the quality as the life, integrity, responsibility, focus, innovation.We will provide professional, quality in return for the trust of customers, with most major global suppliers,all of our employees will work together and move forward together.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!