Chinese Professional Why Austenitic Steel Is Non Magnetic - High speed steel M35 Pan Round – Herui Detail:

Video

Pan round, also known as pan bar, is the name commonly used in building construction, indicating that the diameter of the steel bar is less than 10mm, because the steel bar below 10mm is easy to bend, in order to reduce the length before transportation, it is rolled into a very long circle in the manufacturer, in the construction site, such a steel bar is referred to as pan round.

The surface of the disc is iron oxide, also known as decarburised layer, the colour is dark green, the heavier the colour, the better the texture.

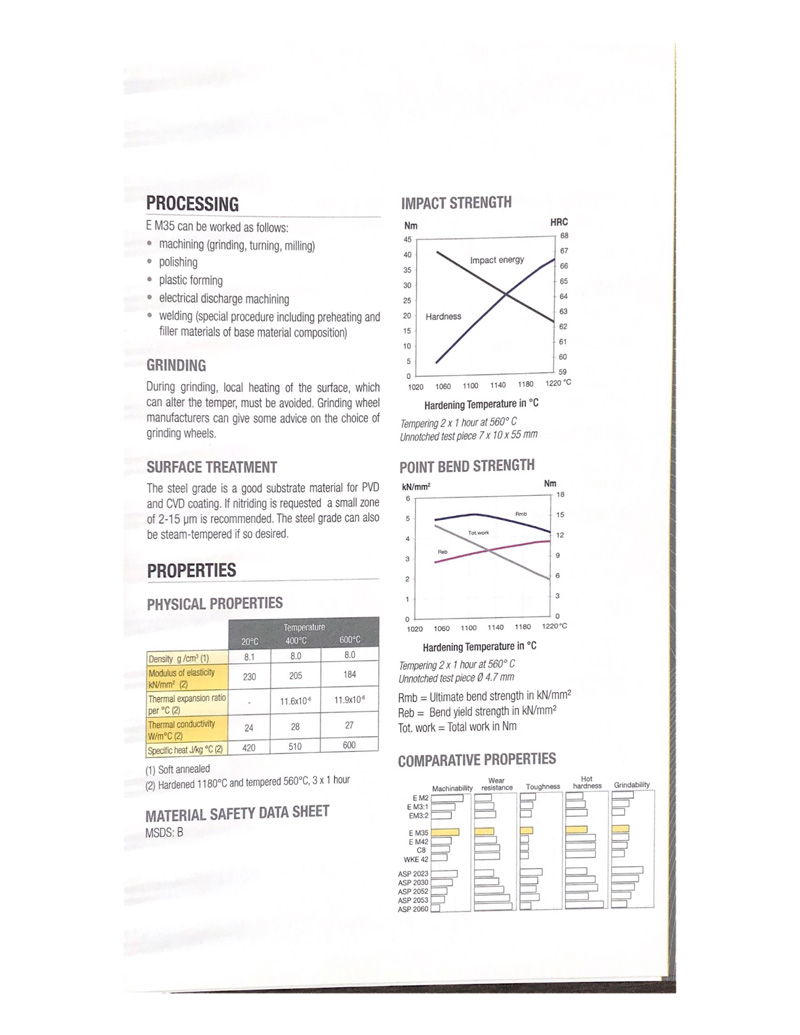

M35 is equivalent to domestic mould steel: W6Mo5Cr4V2Co5 Standard: GB/T 9943-1988, through appropriate heat treatment, can get high hardness (HRC67 ~ 70), high red hardness (625 ℃ 4 hours, HRC63 ~ 65) and high wear resistance, suitable for the manufacture of strong cutting with wear resistance, impact resistance of various tools, advanced punching die, screw die, more need toughness and The product is suitable for the manufacture of tools with high abrasion and impact resistance for powerful cutting, advanced punching dies, screw dies, tools with complex shapes, reamers, milling cutters, iron heads, punches etc. The main applications are hobs, broaches, end mills, easy hot and cold machining; hardened and tempered to the same hardness as M35 and M42, (66±1) HRC and (67±1) HRC respectively.

The m35 cobalt-containing high speed steel is inexpensive and easy to process, through appropriate heat treatment, can obtain high hardness (HRC67~70), high red hardness (625℃4 hours, HRC63~65) and high wear resistance, toughness and flexural strength are not lower than the ordinary type of high-speed steel, can overcome the die edge collapse and chipping and other early damage. Characteristics and applications: This steel is tungsten steel high speed. It is suitable for the manufacture of strong cutting with wear and impact resistance of various tools, advanced punching dies, screw dies, more tough and complex shaped tools, reamers, milling cutters, iron heads, punches, etc. The main applications are hobs, broaches and end mills.

M35 steel is an internationally used super hard high speed steel containing cobalt with high wear resistance, high pressure and sintering resistance. The steel is expensive because it contains cobalt. In order to reduce the price, China has developed a cheap super-hard high-speed steel without cobalt M2Al, to replace the super-hard high-speed steel M35 and M42 steel. M2Al steel process performance is better than M35, easy to carry out hot and cold processing; hardened and tempered with M35 and M42 the same hardness, respectively (66 ± 1) HRC and (67 ± 1) HRC.

Description

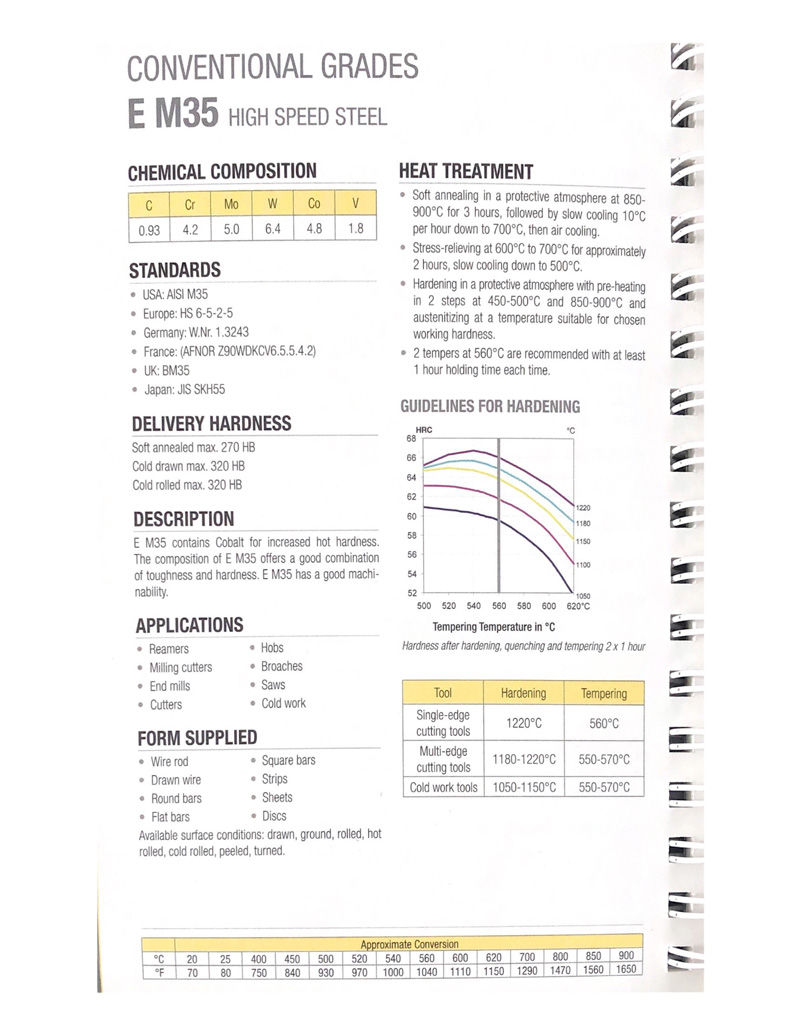

Chemical composition

Carbon C: 0.80 to 0.90 (tolerance: ±0.01)

Silicon Si: 0.20 to 0.45 (Allowable deviation: ±0.05)

Manganese Mn:0.15~0.40(Allowable deviation:+0.04)

Sulfur S: ≤0.030

Phosphorus P:≤0.030

Chromium Cr:3.75~4.50(Allowable deviation:±0.05)

Nickel Ni: residual content ≤0.30

Copper Cu: residual content ≤0.25

Vanadium V:1.75~2.25(Allowable deviation:±0.05)

Molybdenum Mo:4.50~5.50(Allowable deviation: size≤6,±0.05;size>6,±0.10)

Tungsten W : 5.50~6.50(Allowable deviation: size≤10,±0.10;size>10,±0.20)

Cobalt Co:4.50~5.50(Allowable deviation:±0.15)

Product detail pictures:

Related Product Guide:

During the past few years, our business absorbed and digested state-of-the-art technologies the two at home and abroad. Meanwhile, our firm staffs a group of experts devoted to your development of Chinese Professional Why Austenitic Steel Is Non Magnetic - High speed steel M35 Pan Round – Herui, The product will supply to all over the world, such as: Hanover, Russia, Austria, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

-

High reputation Hss M2 Material - Factory pric...

-

Best quality High Speed Steel Cutting Tools - ...

-

Fixed Competitive Price Incoloy 800h - Elgiloy...

-

China Cheap price Machining Monel 400 - Factoe...

-

Hot sale Temperature Steel Becomes Non Magnetic...

-

Super Lowest Price Non Oriented Silicon Steel -...