Factory made hot-sale Uns N08811 - HeRui Factory Supply Good Quality Nickel Alloy Inconel 718 Kovar Invar 36 Bar Rods – Herui Detail:

- Place of Origin:

-

Jiangsu, China

- Type:

- Application:

-

Electromagnet pole head

- Grade:

-

FeCo50V2

- Ni (Min):

-

49% Co and 2% V

- Resistance (μΩ.m):

-

41mm2/m

- Powder Or Not:

-

Not Powder

- Ultimate Strength (≥ MPa):

-

1340

- Elongation (≥ %):

-

9

- Model Number:

-

fe cobalt vanadium alloy

- Brand Name:

-

HeRui

- Product name:

-

Nickel Alloy Inconel 718 Kovar Invar 36 Bar Rods

- Standard:

-

ASTM A801

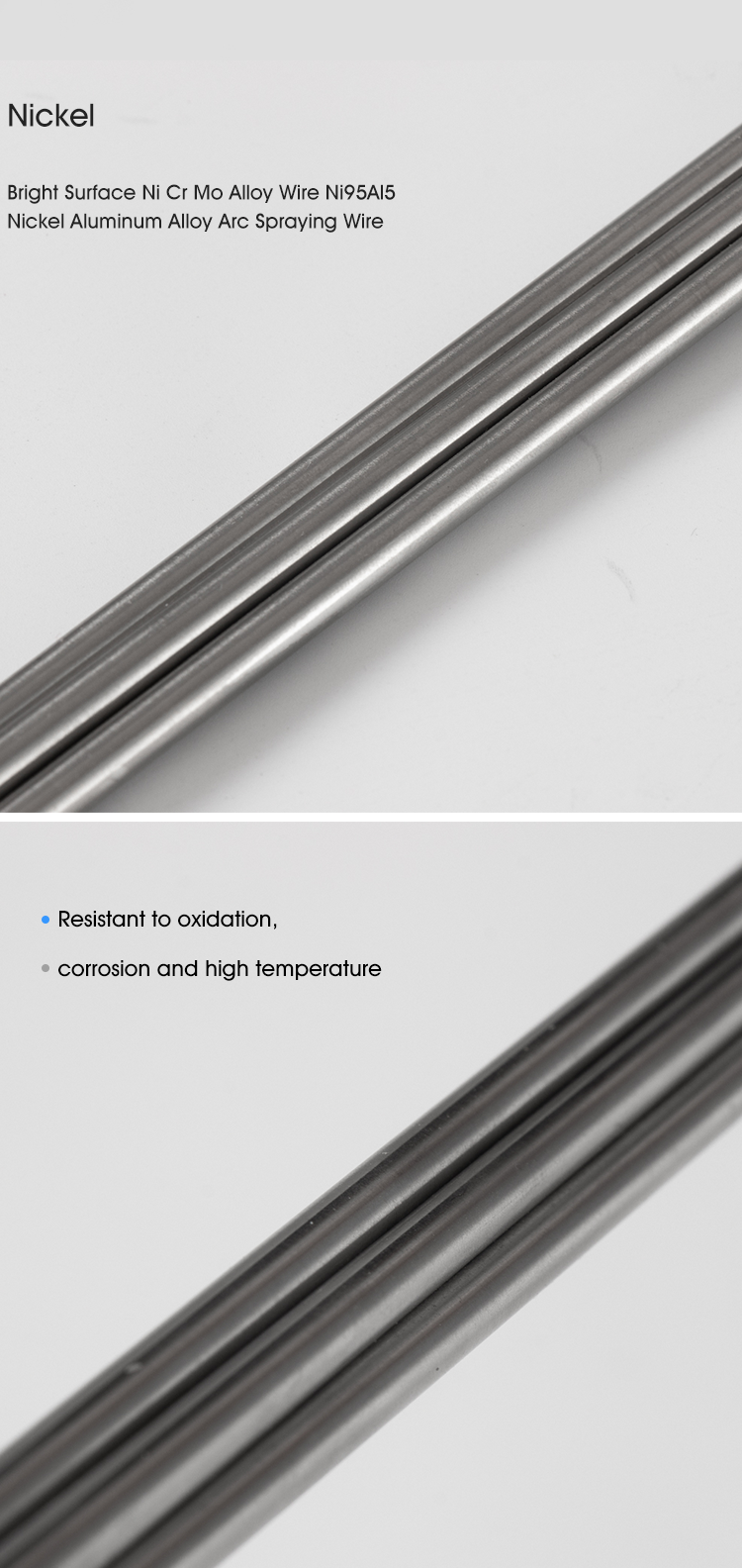

- Surface:

-

Bright

- Delivery Time:

-

30 Days

- Shape:

-

Bar, Plate

- Size:

-

Customized

|

Forms of supply

|

||||

|

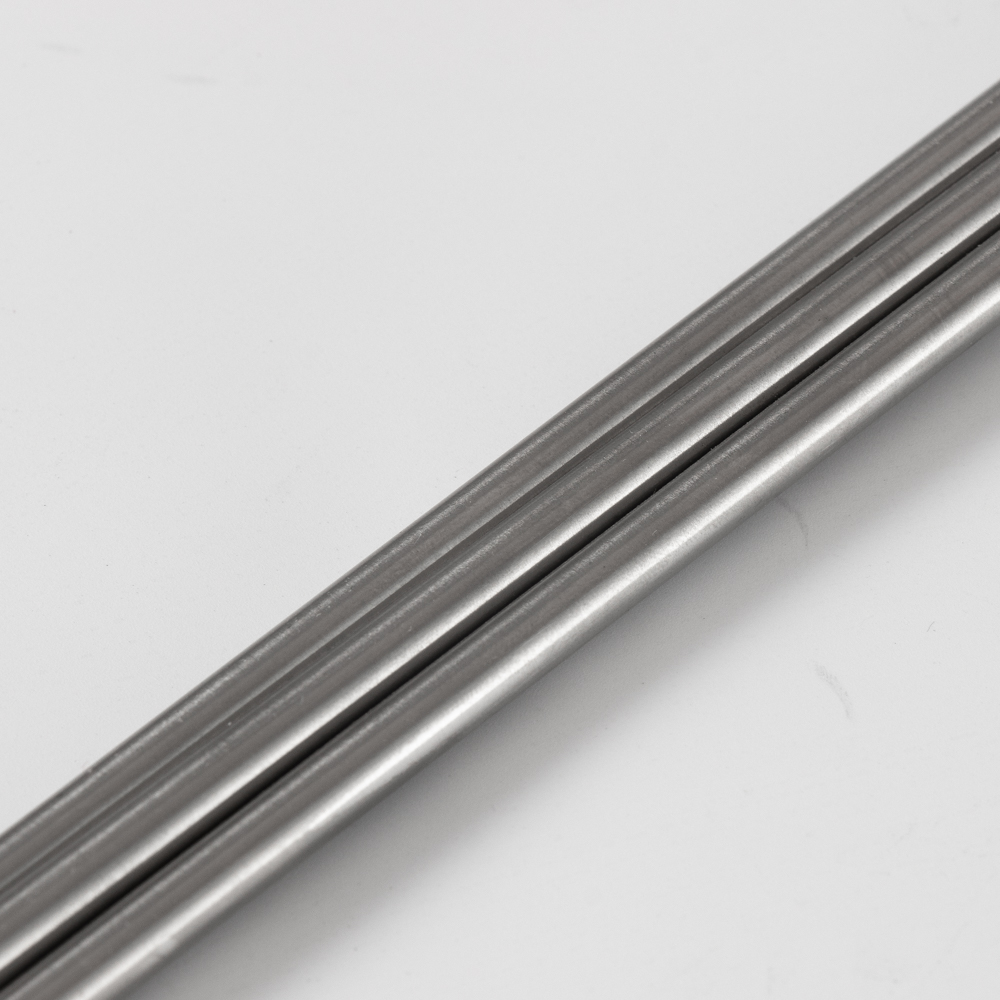

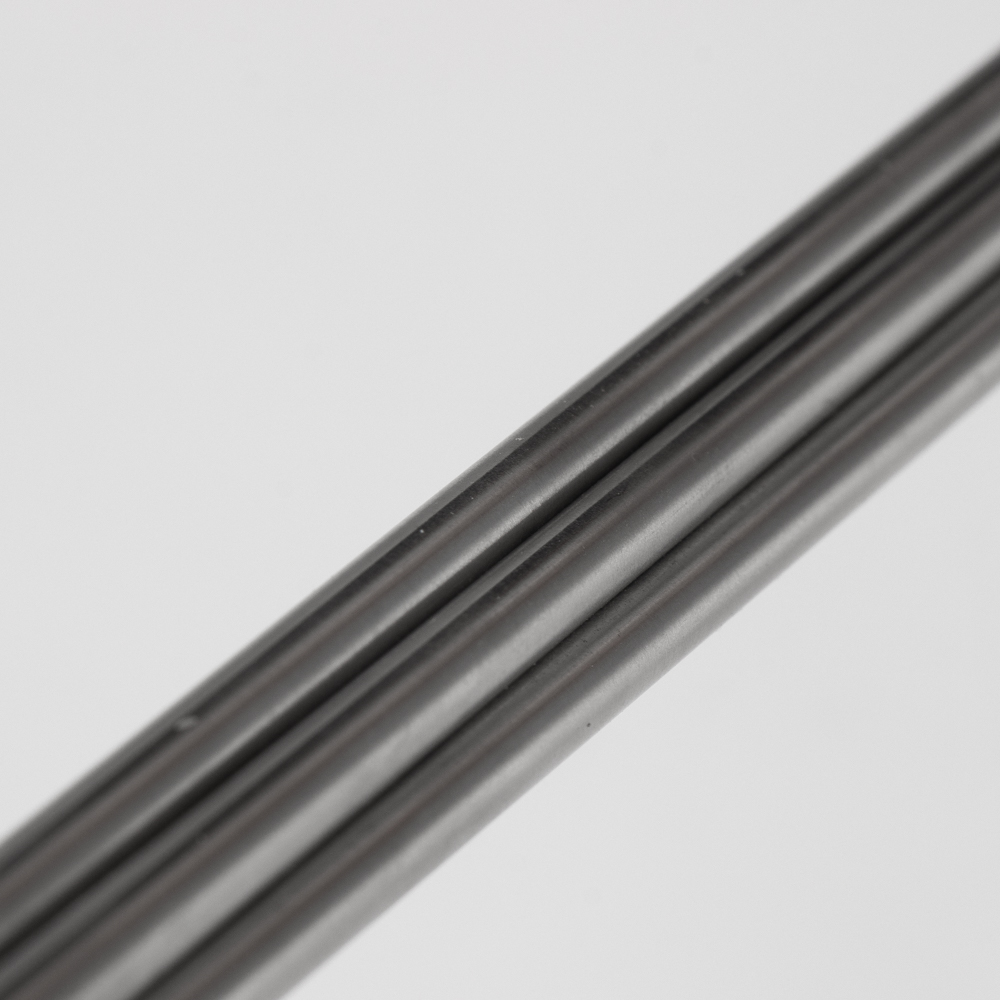

ROD

|

Dia.20 to180mm, Length2000mm,Max

|

Surface Finish: Black, De-scaling & Ground Surface

|

||

|

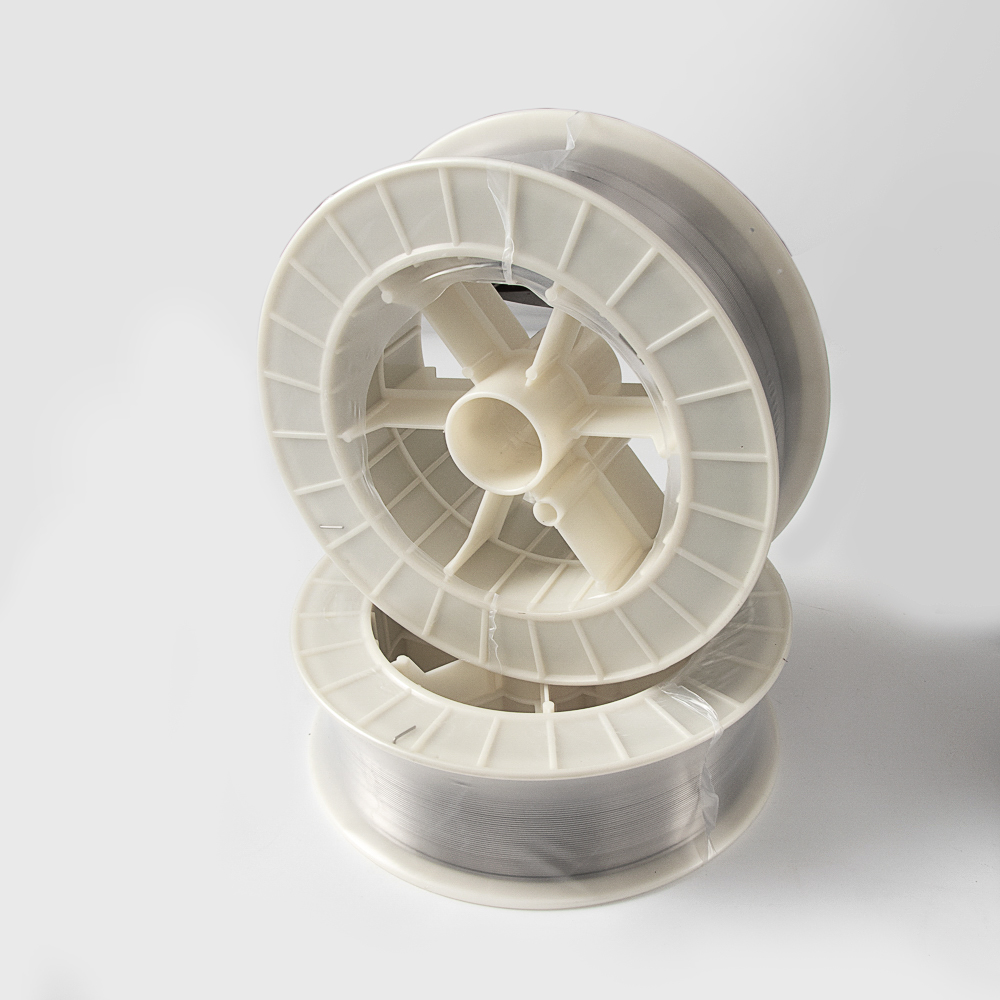

STRIP/SHEET

|

T0.1 to 3.0mm, width300mm,Max

|

Temper Name : Hard / Annealed

|

||

|

PLATE

|

T3.0 to 40.0mm, Width1000mm,Max

|

Surface Finish: Black / Bright

|

||

|

Chemical Composition,%

|

||||||||||||||||||

|

C Max

|

Mn Max

|

Si Max

|

P Max

|

S Max

|

Cr Max

|

Ni Max

|

Co

|

V

|

Fe

|

|||||||||

|

0.025

|

0.15

|

0.15

|

0.015

|

0.01

|

0.15

|

0.25

|

47.5-49.5

|

1.75-2.10

|

Bal.

|

|||||||||

|

DC Magnetic Properties

|

||||||||||

|

Forms

|

Magnetic induction at different magnetic field B,≥(T)

|

Coercivity Hc,≤(A/m)

|

||||||||

|

B800

|

B800

|

B800

|

B800

|

|||||||

|

Cold-Rolling Strip

|

2.00

|

2.00

|

2.00

|

2.00

|

128

|

|||||

|

Forgings ,Bar

|

1.50

|

1.50

|

1.50

|

1.50

|

144

|

|||||

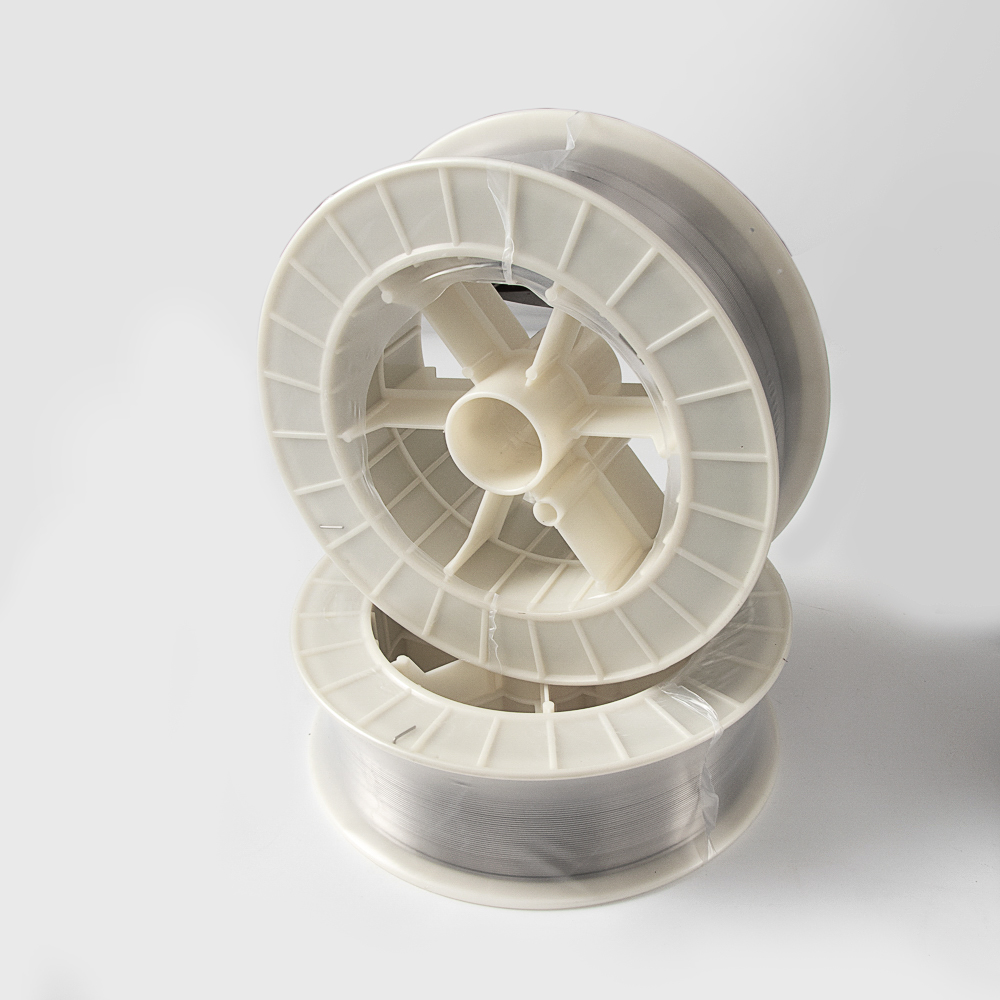

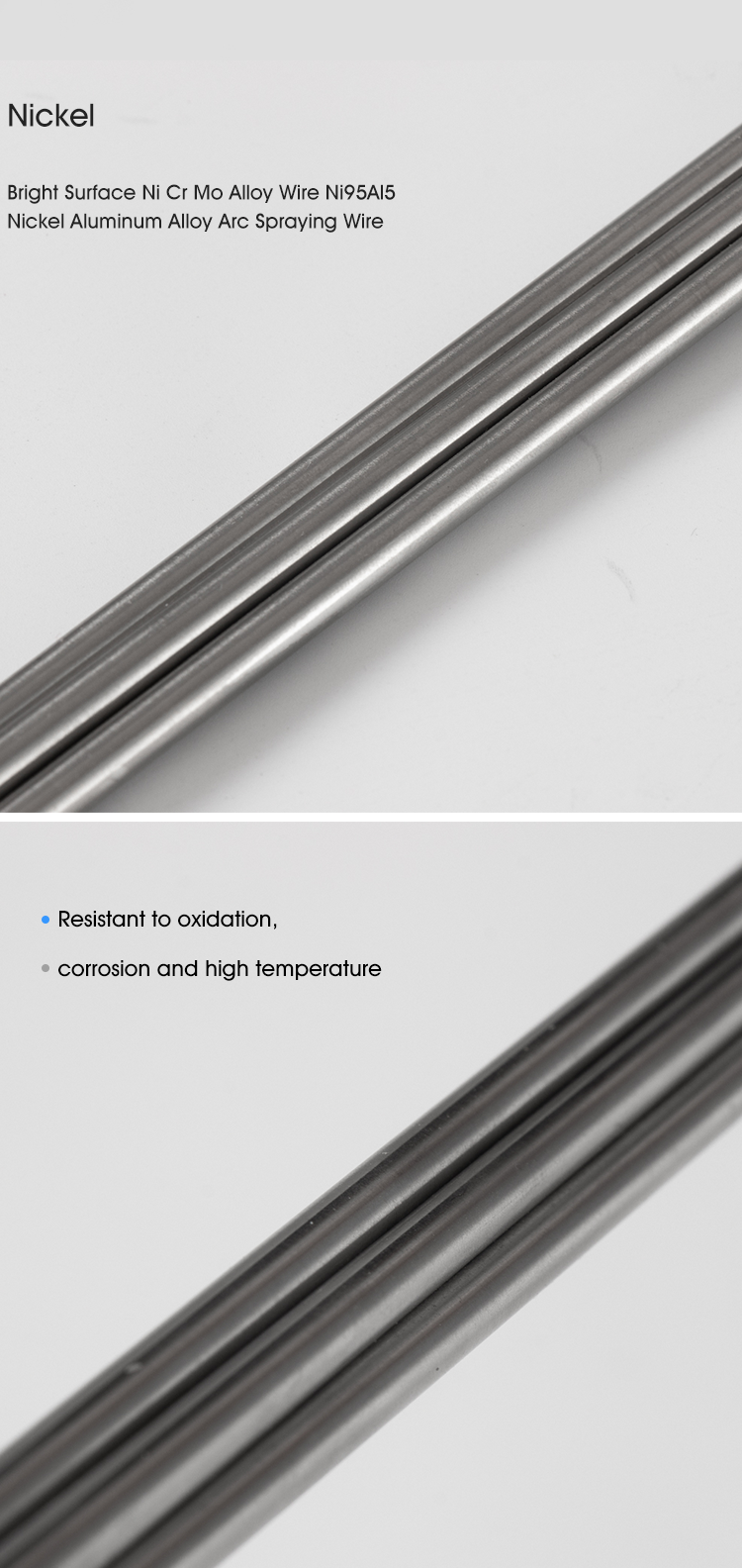

Product detail pictures:

Related Product Guide:

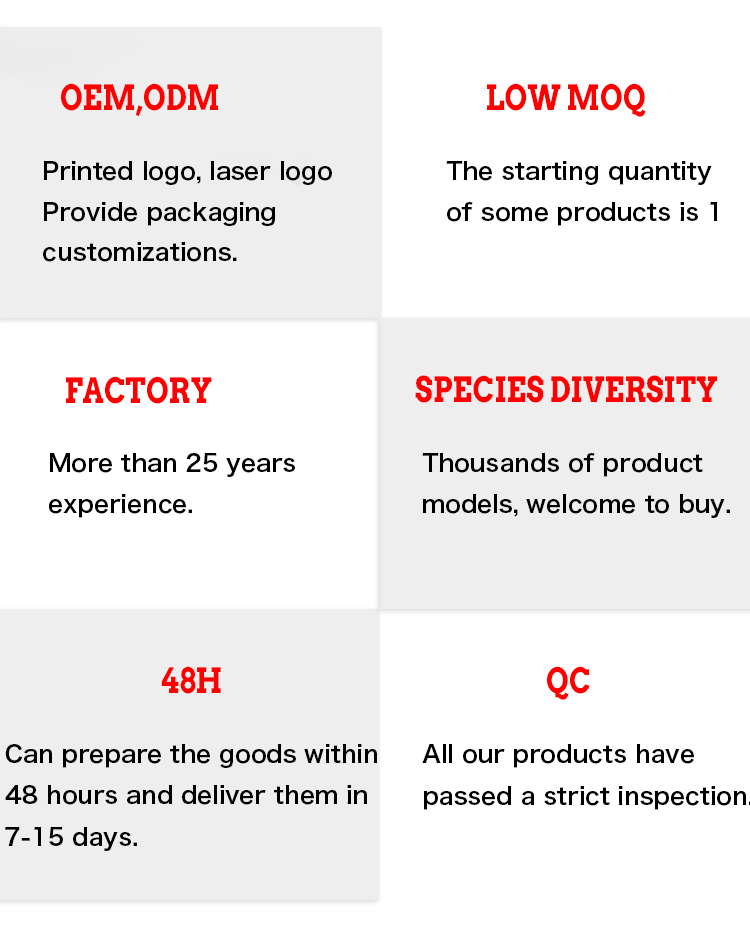

owing to fantastic assistance, a variety of high quality goods, aggressive rates and efficient delivery, we love a very good popularity among our customers. We are an energetic firm with wide market for Factory made hot-sale Uns N08811 - HeRui Factory Supply Good Quality Nickel Alloy Inconel 718 Kovar Invar 36 Bar Rods – Herui, The product will supply to all over the world, such as: Milan, Namibia, South Korea, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we provide, effective and satisfying consultation service is supplied by our professional after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So you should make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We've been confident that we have been going to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.

-

High reputation M2 Steel Price - Elgiloy alloy...

-

China Manufacturer for Capillary Tube Cutter -...

-

Factory directly supply High Speed Steel Tool B...

-

Free sample for M2 Steel - Wholesale Price Nic...

-

Low price for Non Oriented Electrical Steel - ...

-

New Delivery for Capillary Transfer Tubes - Fa...