Factory Supply Monel Stainless Steel - Hymu80 (Permalloy80 / Mumetal) – Herui Detail:

Chemical Composition

| C | P | S | Cu | Mn | Si | Mo | Ni | Fe |

| ≤ | ||||||||

| 0.03 | 0.020 | 0.020 | 0.20 | 0.60-1.10 | 0.30-0.50 | 3.8-4.1 | 78.5-80.0 | Balance |

Characters

Hymu80 is only moderately resistant to moisture and atmospheric corrosion; it used mainly in in transformer cores but is well known for its magnetic properties which are used for shielding electrical components from magnetic fields. “HYMU 80″ has a minimum DC permeability of 80,000 at a flux density of 40 gauss when heat treated by the recommended procedure and test in accordance with ASTM 596.

Specific Gravity – 8.7g/cm

Curie Temperature – 830°F (410°C)

Applications

High performance magnetic cores such as toroids and stacked laminations

Magnetic shielding to protect sensitive components from extraneous magnetic fields

Magnetic sensors

Current sensors

Any application requiring high permeability magnetic material, with a low coercive field and low losses, in the range from low frequency up to 1MHz

Vacuum chamber vessels and liners

Equal grades

Permalloy 80

HYMU 80

MAG 7904

MIL N 14411 C, COMP. 1

UNS N14080

Mumetal

PC(Japan)

1J79(China)

Forms available

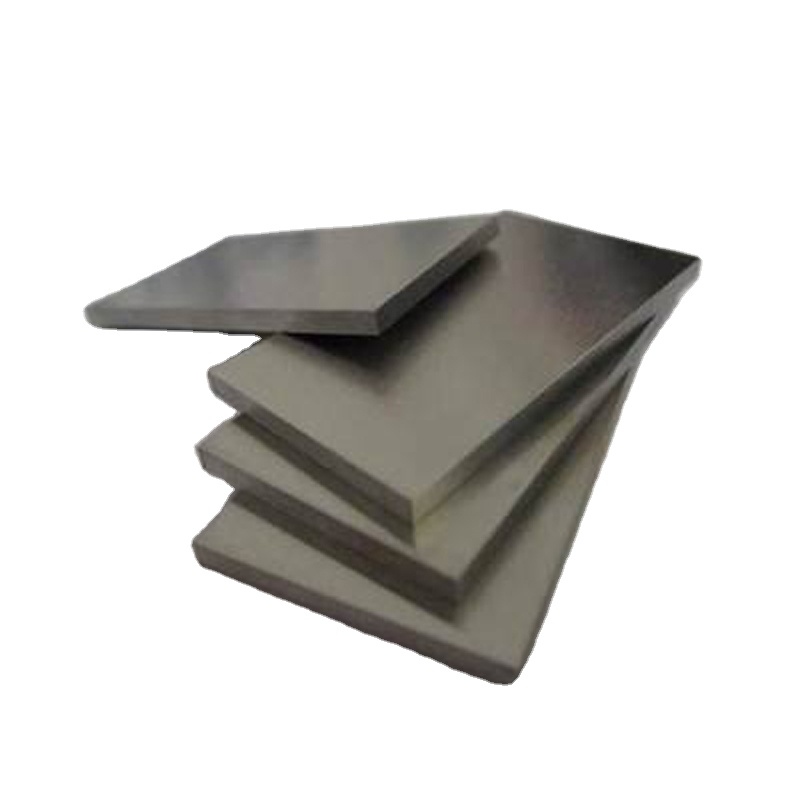

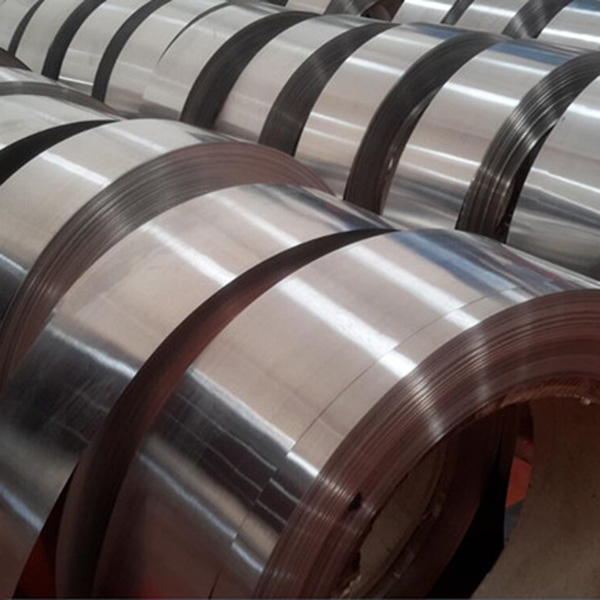

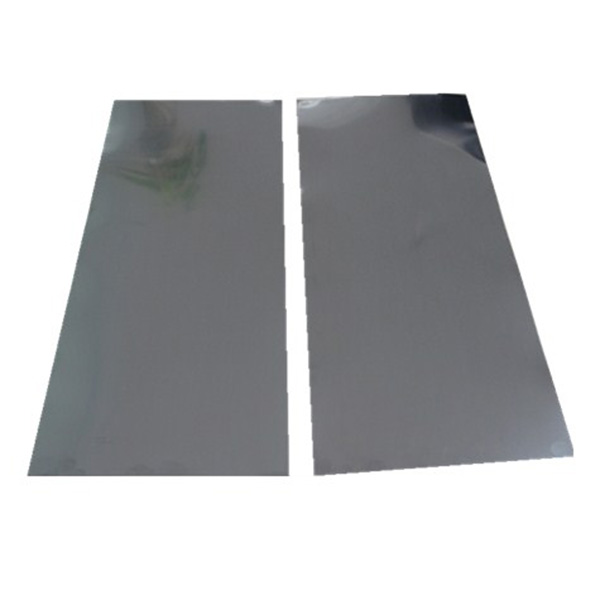

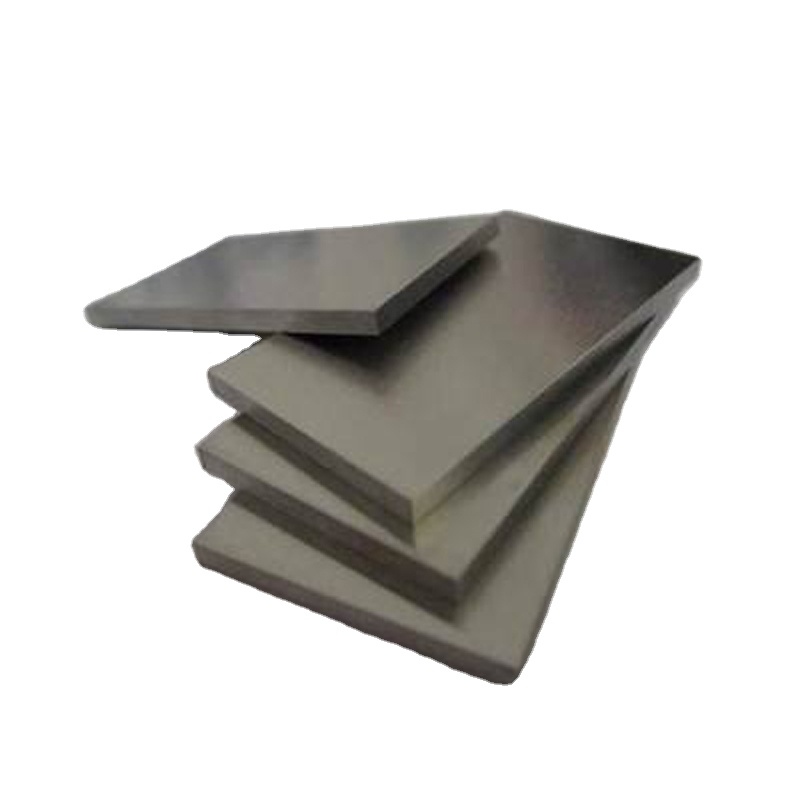

Plate, sheet, strip, wire, rod, bar, tube

Product detail pictures:

Related Product Guide:

The corporate upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will keep on to serve outdated and new clients from home and abroad whole-heatedly for Factory Supply Monel Stainless Steel - Hymu80 (Permalloy80 / Mumetal) – Herui, The product will supply to all over the world, such as: New Delhi, Barbados, Brasilia, Our products and solutions are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, be sure to contact us today. We will sincerely create and share success with all clients.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.

-

Big Discount High Speed Stainless Steel Wholesa...

-

Chinese wholesale High Speed Steel 4241 - High...

-

factory Outlets for Inconel 400 - High quality...

-

Special Design for Incoloy 903 - Elgiloy alloy...

-

Factory Cheap Capillary Collection Tubes - HeR...

-

China Cheap price Machining Monel 400 - High q...