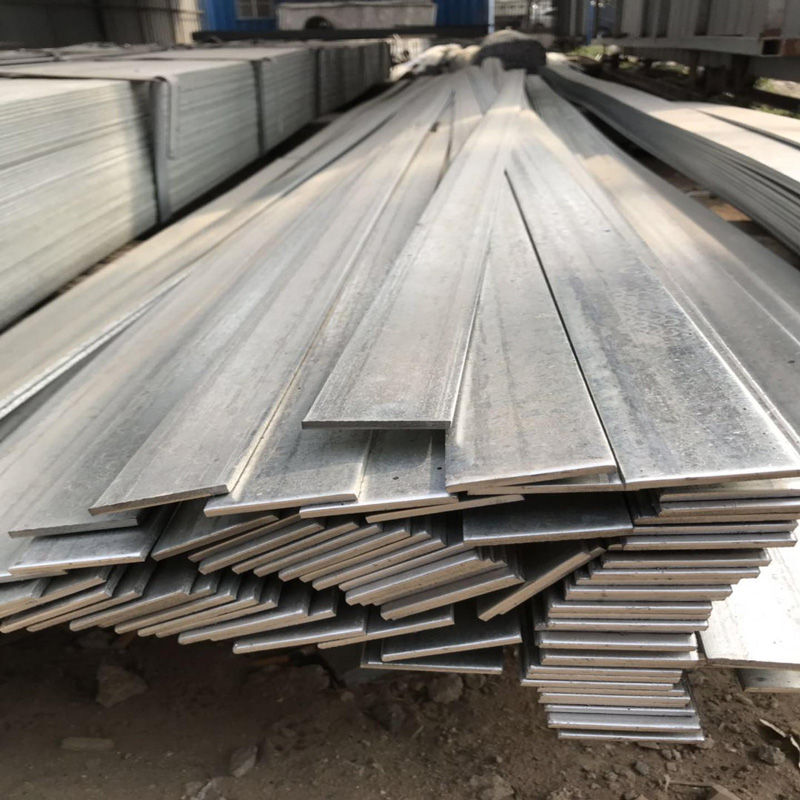

Fast delivery Hss Flat Bar - High speed steel flat steel – Herui Detail:

Video

Precise product scale, three-point difference, the same level difference are better than the steel plate standard; the product is straight and the plate shape is good.we adopt continuous rolling process for the finishing rolling , automatic looper automatic control, to ensure that no steel is piled or stretched, and the product size is high. The tolerance range, three-point difference, same stripe, sickle bend and other parameters are all better than the medium plate, and the plate shape is straight. Degree is good. Cold shearing, high precision of length setting.

The approximate value of 4341 elements for high-speed steel material is : chromium 4 molybdenum 3 tungsten 4 vanadium 1, and the corresponding grade is: W4Mo3Cr4VSi

The heat treatment process of high-speed steel is more complicated and must go through a series of processes such as annealing, quenching, and tempering. The purpose of annealing is to eliminate stress, reduce hardness, make the microstructure uniform, and facilitate quenching. The annealing temperature is generally 860 to 880°C. Quenching is generally carried out in two stages due to its poor thermal conductivity. First preheat at 800~850℃ (so as not to cause large thermal stress), then quickly heat to the quenching temperature 1190~1290℃ (different grades have different temperatures in actual use), then oil cooling or air cooling or gas-filled cooling. All factories use salt furnaces for heating, and vacuum furnaces are now widely used. After quenching, a part (about 30%) of retained austenite is not transformed into martensite because of the internal structure, which affects the performance of high-speed steel. In order to transform the retained austenite and further improve the hardness and wear resistance, generally 2 to 3 times of tempering are required, the tempering temperature is 560℃, and the heat preservation is 1 hour each time.

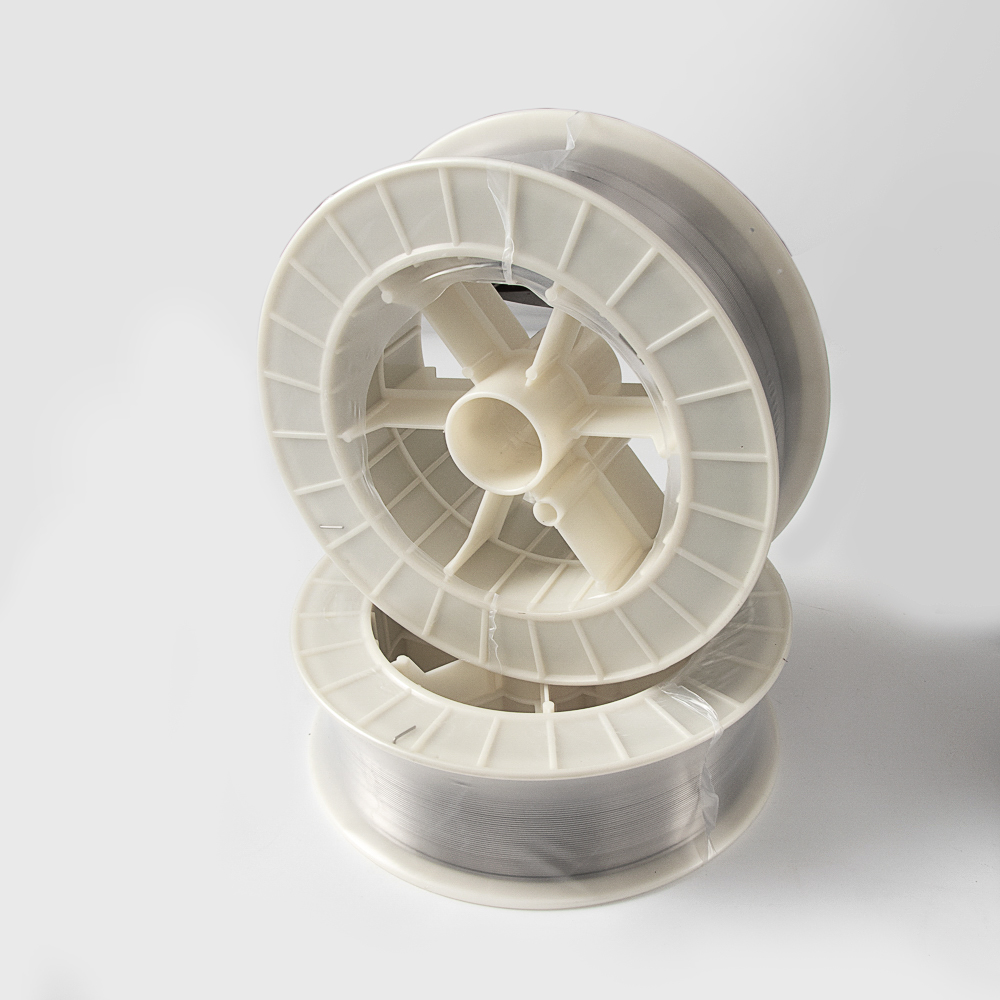

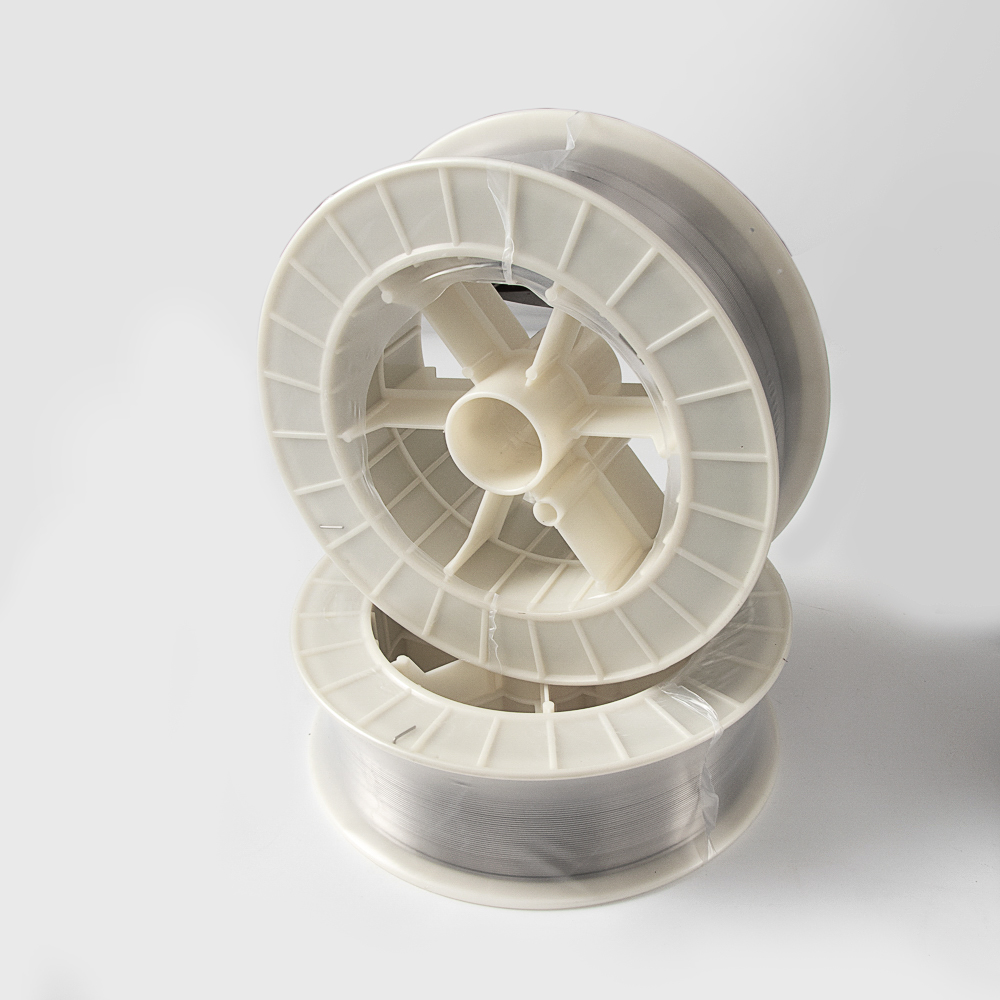

Product detail pictures:

Related Product Guide:

In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of Fast delivery Hss Flat Bar - High speed steel flat steel – Herui, The product will supply to all over the world, such as: Libya, Victoria, Russia, We firmly think that we have the full capability to give you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.

-

Hot Selling for Inconel 825 Filler Wire - Elgi...

-

Low MOQ for Hematocrit Tubes - Elgiloy alloy (...

-

Good User Reputation for High Speed Metal Whole...

-

Manufacturing Companies for M2 Steel Heat Treat...

-

Factory selling Incoloy 909 - Hymu80 (Permallo...

-

Discount Price High Speed Tool Steel Factory -...