High Performance Battery Welding Strip - Elgiloy alloy (Co40CrNiMo), AMS 5833, UNS R3003, 3J21 – Herui Detail:

Description

This Cobalt-Chromium-Nickel alloy is also known as Elgiloy, it has a combination of high strength, ductility and good mechanical properties and is age harden-able. The Phynox alloy also has excellent fatigue life, corrosion resistance in numerous environments and non-magnetic. This alloy is recommended where a high resistance to corrosion and low relaxation at temperatures up to 380℃ are required.

Chemical Composition (%)

| C | 0.07~0.12, |

| Mn | 1.7~2.3, |

| Si≤0.60 | |

| P≤ | 0.01 |

| S≤ 0.01 | |

| Ni | 14.0~21.0 |

| Cr | 19.0~21.0 |

| Co | 39.0~41.0 |

| Mo | 6.5~7.5 |

| Fe | Balance |

Application

Springs

Seal components

Medical devices

Components for watches

Aerospace applications

Petro-chemical applications

Marine engineering

Equal grades

UNS R30003,3J21,Phynox, W.Nr 2.4711

Forms available

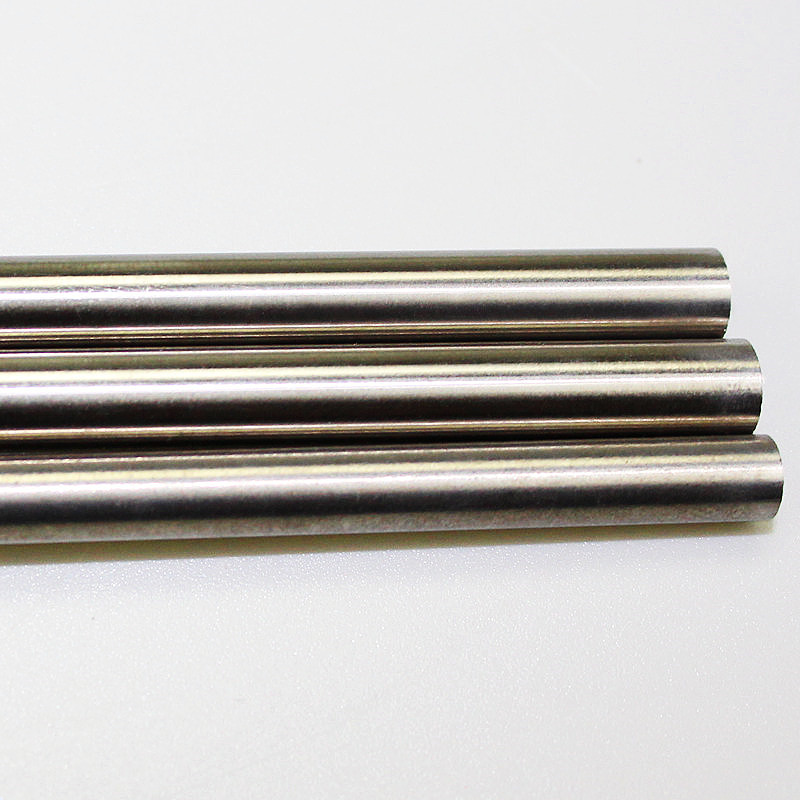

Strip, wire, bar, rod

Product detail pictures:

Related Product Guide:

In an effort to provide you advantage and enlarge our business enterprise, we even have inspectors in QC Staff and assure you our greatest provider and item for High Performance Battery Welding Strip - Elgiloy alloy (Co40CrNiMo), AMS 5833, UNS R3003, 3J21 – Herui, The product will supply to all over the world, such as: Latvia, Georgia, Montreal, All styles appear on our website are for customizing. We meet up to personal requirements with all products of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!