- Place of Origin:

-

Jiangsu, China

- Type:

-

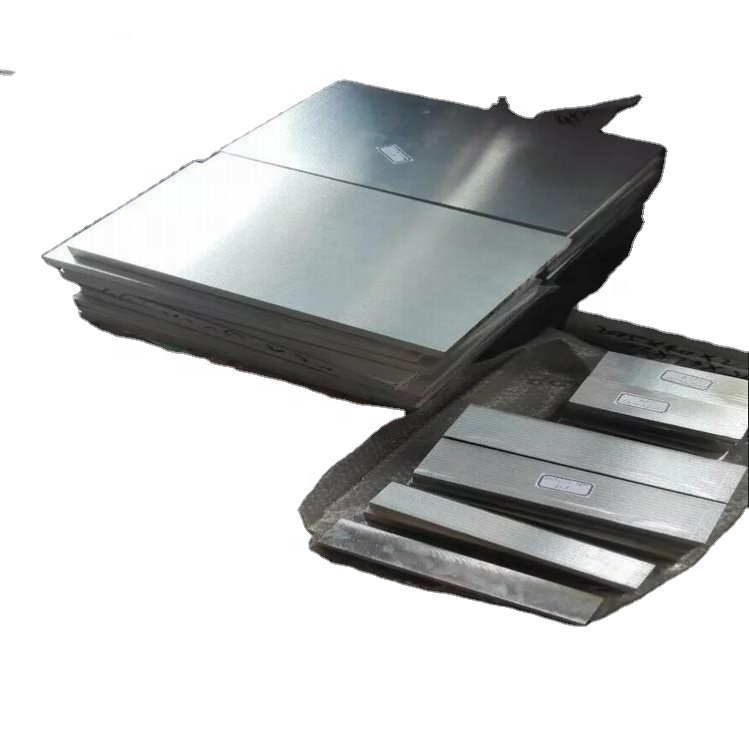

Nickel Plate

- Application:

-

Furnace parts

- Grade:

-

nickel-iron-chromium alloys

- Ni (Min):

-

30%

- Resistance (μΩ.m):

-

As Scheduled

- Powder Or Not:

-

Not Powder

- Ultimate Strength (≥ MPa):

-

As Scheduled

- Elongation (≥ %):

-

As Scheduled

- Model Number:

-

HR-011

- Brand Name:

-

HeRui

- Standard:

-

ASTM B 408

- Surface:

-

Bright

- Delivery Time:

-

30 Days

Incoloy 800 offers general corrosion resistance to many aqueous media and, by virtue of its content of nickel, resists stress corrosion cracking. At elevated temperatures it offers resistance to oxidation, carburization, and sulfidation along with rupture and creep strength. For applications requiring greater resistance to stress rupture and creep, especially at temperatures above 1500°F (816°C), INCOLOY alloys 800H and 800HT are used.

Application

INCOLOY 800 is used in a variety of applications involving exposure to corrosive environments and high temperatures. It is used for heat-treating equipment such as baskets, trays, and fixtures. In chemical and petrochemical processing, the alloy is used for heat exchangers and other piping systems in nitric acid media especially where resistance to chloride stress-corrosion cracking is required.

In nuclear power plants, it is used for steam-generator tubing. The alloy is often used in domestic appliances for sheathing of electric heating elements. In the production of paper pulp, digester-liquor heaters are often made of alloy 800. In petroleum processing, the alloy is used for heat exchangers that air cool the process stream.

Equal grades

UNS N08800, W. Nr. 1.4876, NS111(China)

Chemical composition

Nickel: 30.0-35.0

Chromium: 19.0-23.0

Iron: 39.5 min.

Carbon: 0.10 max.

Manganese: 1.50 max.

Sulfur: 0.015 max.

Silicon: 1.0 max.

Copper: 0.75 max.

Aluminum: 0.15-0.60

Titanium: 0.15-0.60

Available Product Forms: Pipe, tube, sheet, plate, round bar, forging stock and wire.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.