Leading Manufacturer for Inconel 625 Round Bar - Monel 400 – Herui Detail:

Description

MONEL 400 (nickel-copper alloy, UNS N04400 / W. Nr. 2.4360 and 2.4361) is a solid-solution alloy that can be hardened only by cold working. It has high strength and toughness over a wide temperature range and excellent resistance to many corrosive environments. Monel 400 is widely used in many fields, especially marine and chemical processing. Typical applications are valves and pumps, pump and propeller shafts, marine fixtures and fasteners, electrical and electronic components, springs, chemical processing equipment, gasoline and fresh water tanks, crude petroleum stills, process vessels and piping, boiler feedwater heaters and other heat exchangers, and deaerating heaters.

Limiting Chemical Composition, %

| Nickel (plus Cobalt) | 63.0 min. |

| Carbon | 0.3 max. |

| Manganese | 2.0 max. |

| Iron | 2.5 max. |

| Sulfur | 0.024 max. |

| Silicon | 0.5 max. |

| Copper | 28.0 – 34.0 |

Application

Pumps, valves, and fittings, marine engineering, chemical and hydrocarbon processing equipment, shafts, fasteners, and heat exchangers.

Equal grade

UNS N04400, Alloy 400

Forms of Monel 400 available

Plate, strip, bar, wire, pipe, forging, flange, fastener

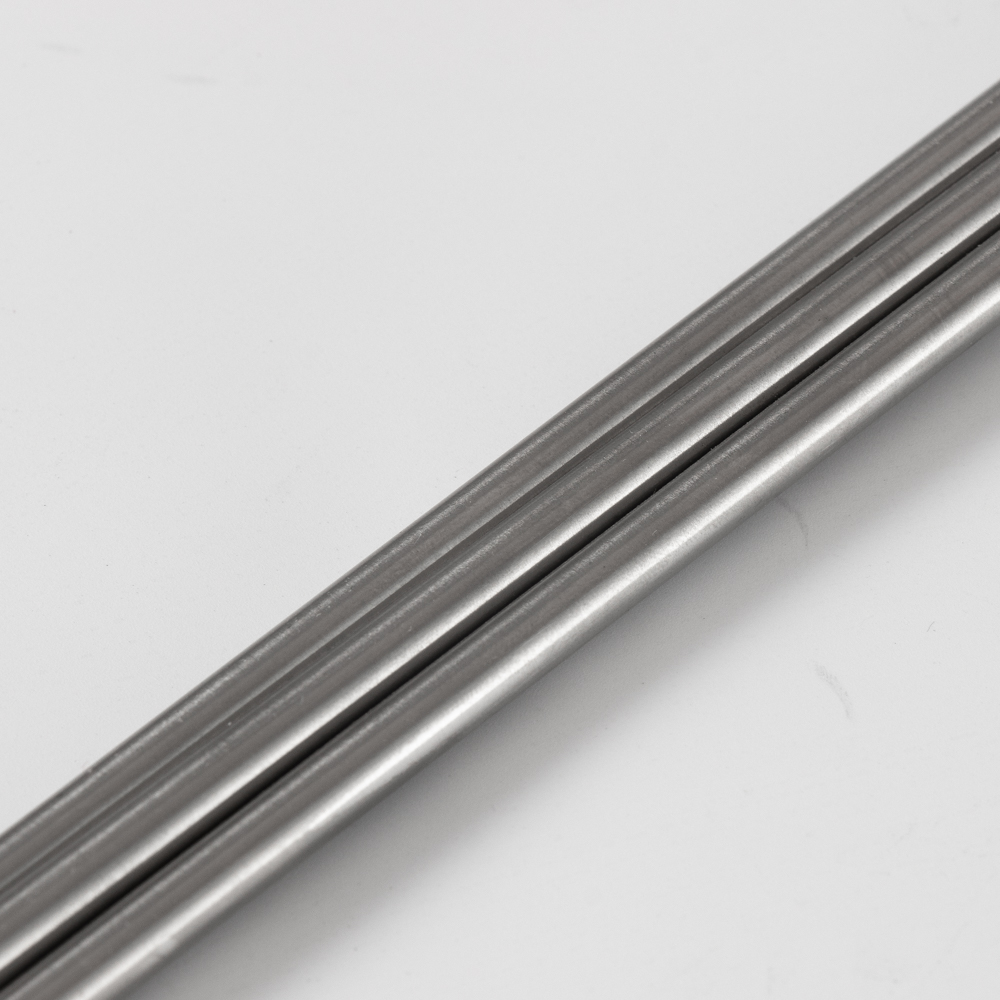

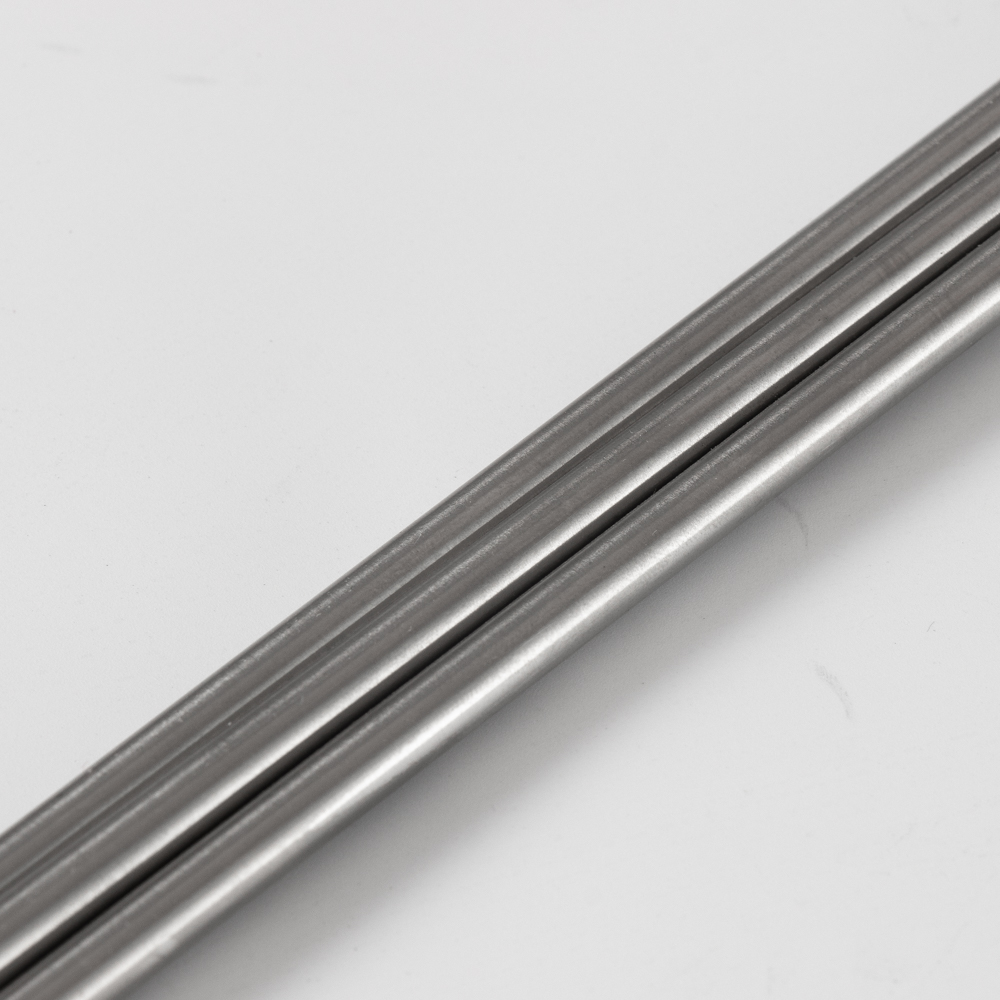

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Leading Manufacturer for Inconel 625 Round Bar - Monel 400 – Herui, The product will supply to all over the world, such as: Amsterdam, Peru, Chile, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.

-

Discount Price Incoloy Adalah - Manufacture pr...

-

Hot Sale for Monel 67 - Super Quality Hot Sell...

-

factory customized Non Magnetic Steel Screws -...

-

Reasonable price for Alloy K500 - China suppli...

-

China Supplier Glass Capillary Tube - Factory ...

-

Factory directly supply Non Magnetic Steel Plat...