Manufacturer of Ngo Electrical Steel - Invar, Invar 36, NILO 36 & Pernifer 36 / UNS K93600 & K93601 / W. Nr. 1.3912 – Herui Detail:

Description

Invar (also know as Invar 36, NILO 36, Pernifer 36 and Invar Steel) is a low expansion alloy consisting of 36% Nickel, balance Iron. Invar Alloy exhibits extremely low expansion around ambient temperatures, making Invar Alloy particularly useful in applications where minimum thermal expansion and high dimensional stability is required, such as in precision instruments like optoelectronic devices, optical and laser benches, electronics, and other kinds of scientific instruments.

Chemistry By % Weight

| C | 0.02% |

| Fe | Balance |

| Mn | 0.35% |

| Ni | 36% |

| Si | 0.2% |

Typical Mechanical Properties

| Ultimate Tensile Strength | 104,000 PSI |

| Yield Strength | 98,000 PSI |

| Elongation @ Break | 5.5 |

| Modulus of Elasticity | 21,500 KSI |

Typical Physical Properties

| Density | 0.291 lbs/cu in |

| Melting Point | 1425° C |

| Electrical Resistivity @ RT | 8.2 Microhm-cm |

| Thermal Conductivity @ RT | 10.15 W/m-k |

Available Product Forms

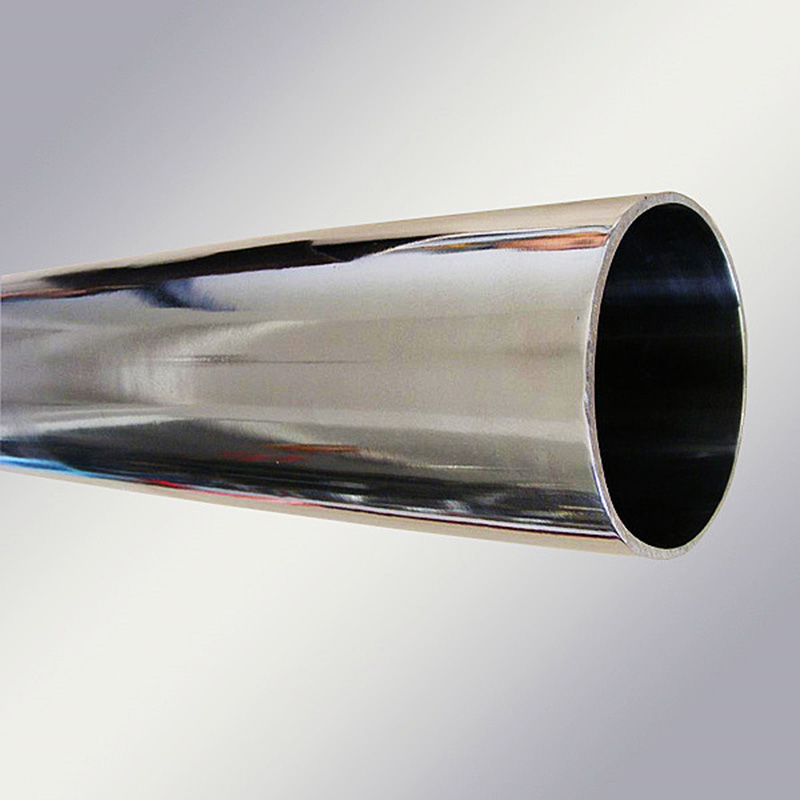

Pipe, tube, sheet, plate, round bar, forging stock and wire.

Keywords

Invar 36, Pernifer 36, Nilo 36, Invar Steel, Iron-Nickel Alloy, Low Expansion Alloys, Precision Instruments Applications

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for Manufacturer of Ngo Electrical Steel - Invar, Invar 36, NILO 36 & Pernifer 36 / UNS K93600 & K93601 / W. Nr. 1.3912 – Herui, The product will supply to all over the world, such as: Milan, Sri Lanka, Netherlands, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing merchandise, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

-

Competitive Price for Copper Capillary Tube - ...

-

Cheapest Factory Microvette Capillary Blood Col...

-

Factory Cheap Hot Machining Monel - Hot-sellin...

-

Factory wholesale M2 Tool Steel Supplier - ERN...

-

professional factory for 800ht - Api Standard ...

-

2021 Good Quality German Silver Wire - Elgiloy...