Massive Selection for Fused Silica Capillary - Elgiloy alloy (Co40CrNiMo), AMS 5833, UNS R3003, 3J21 – Herui Detail:

Description

This Cobalt-Chromium-Nickel alloy is also known as Elgiloy, it has a combination of high strength, ductility and good mechanical properties and is age harden-able. The Phynox alloy also has excellent fatigue life, corrosion resistance in numerous environments and non-magnetic. This alloy is recommended where a high resistance to corrosion and low relaxation at temperatures up to 380℃ are required.

Chemical Composition (%)

| C | 0.07~0.12, |

| Mn | 1.7~2.3, |

| Si≤0.60 | |

| P≤ | 0.01 |

| S≤ 0.01 | |

| Ni | 14.0~21.0 |

| Cr | 19.0~21.0 |

| Co | 39.0~41.0 |

| Mo | 6.5~7.5 |

| Fe | Balance |

Application

Springs

Seal components

Medical devices

Components for watches

Aerospace applications

Petro-chemical applications

Marine engineering

Equal grades

UNS R30003,3J21,Phynox, W.Nr 2.4711

Forms available

Strip, wire, bar, rod

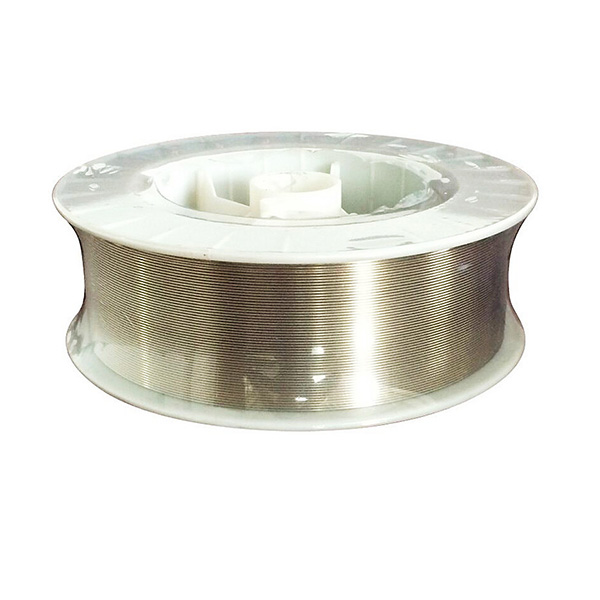

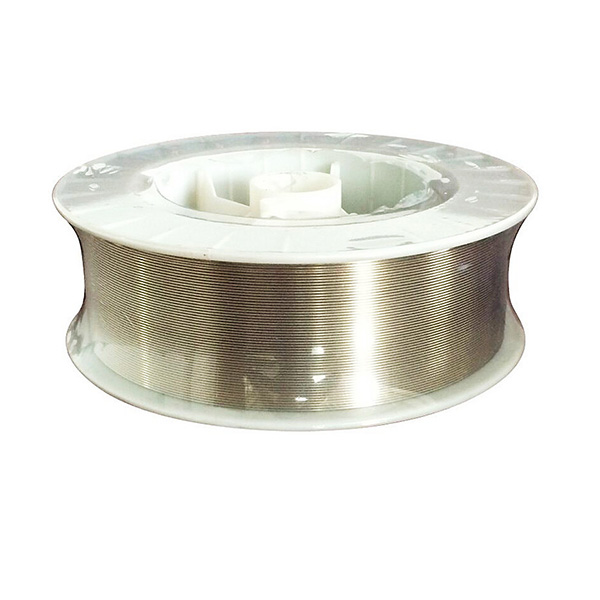

Product detail pictures:

Related Product Guide:

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for Massive Selection for Fused Silica Capillary - Elgiloy alloy (Co40CrNiMo), AMS 5833, UNS R3003, 3J21 – Herui, The product will supply to all over the world, such as: Libya, Bhutan, Chicago, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will be more conveniently to service our customers.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

-

Chinese wholesale M2 Steel - Ni95Al5 / Thermal...

-

Manufacturing Companies for Austenitic Stainles...

-

Hot sale Epoc Capillary Tubes - High quality o...

-

2021 New Style Alloy 625 Wire - Manufacture pr...

-

Competitive Price for Copper Capillary Tube - ...

-

High reputation M2 Steel Price - Techalloy 606...