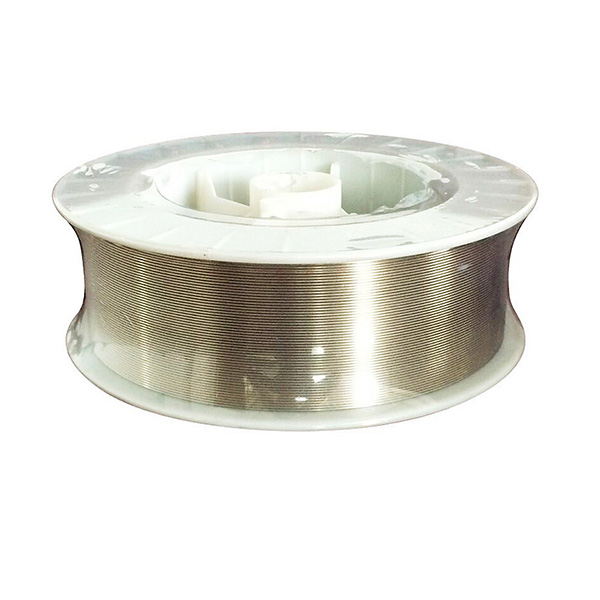

OEM manufacturer 316 Ss Magnetic - High speed steel Pan Round – Herui Detail:

Video

Coils, also known as wire rod, usually refer to small diameter round steel in coils. The diameter of a coil is in the range of 5-19 mm (usually 6-9 mm) and its lower value is the minimum size of a hot rolled steel section.

High Speed Steel (HSS) is a tool steel with high hardness, wear resistance and heat resistance, also known as high speed tool steel or sharp steel, commonly known as white steel. HSS was created by F.W. Taylor and M. White in the USA in 1898.

The process performance of high-speed steel is good, strength and toughness with good, so mainly used to manufacture complex thin-edged and impact-resistant metal cutting tools, but also to manufacture high-temperature bearings and cold extrusion dies. In addition to the production of high-speed steel with the melting method, after the 1960s and the emergence of powder metallurgy high-speed steel, which has the advantage of avoiding the melting method of production caused by the carbide segregation and mechanical properties caused by reduced and heat treatment deformation.

The approximate value of 4341 elements of high speed steel is in fact: chromium 4 molybdenum 3 tungsten 4 vanadium 1, corresponding to the grade is: W4Mo3Cr4VSi

The heat treatment process of high speed steel is more complex and must go through a series of processes such as annealing, quenching and tempering. The purpose of annealing is to eliminate stress, reduce hardness, make the microstructure uniform, easy to quench. Annealing temperature is generally 860 ~ 880 ℃. Quenching due to its poor thermal conductivity is generally carried out in two stages. First in 800 ~ 850 ℃ preheating (so as not to cause large thermal stress), and then quickly heated to quenching temperature 1190 ~ 1290 ℃ (different grades of actual use temperature differences), after oil cooling or air cooling or gas cooling. Factories are heated using salt furnaces, and now vacuum furnaces are also used quite widely. After quenching because the internal organization also retains a part (about 30%) of the residual austenite is not transformed into martensite, affecting the performance of high-speed steel. In order to make the residual austenite transformation, to further improve the hardness and wear resistance, generally 2 to 3 times tempering, tempering temperature 560 ℃, each time the insulation 1 hour.

Translated with www.DeepL.com/Translator (free version)

Product detail pictures:

Related Product Guide:

High quality Very first,and Consumer Supreme is our guideline to offer the most beneficial service to our consumers.At present, we're attempting our greatest to be among the top exporters in our area to fulfill buyers far more need to have for OEM manufacturer 316 Ss Magnetic - High speed steel Pan Round – Herui, The product will supply to all over the world, such as: Suriname, Egypt, Provence, Over the years, with high-quality products, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We provide high quality product and competitive price, welcome the regular and new customers cooperate with us!

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.