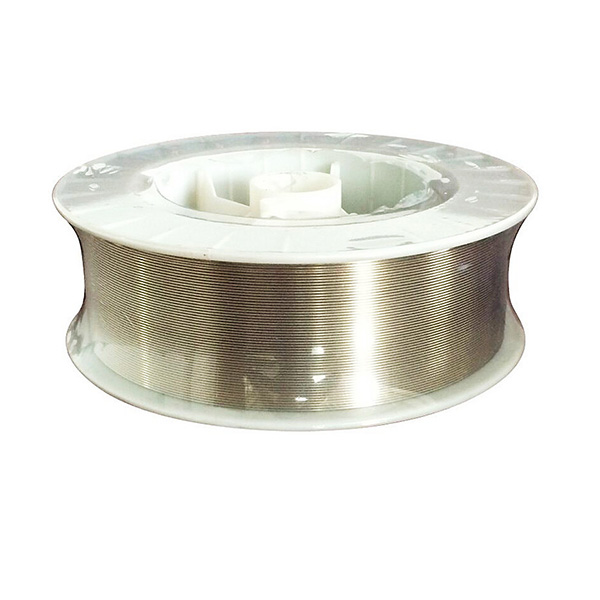

PriceList for Non Magnetic Stainless Steel Scrap Price - Techalloy 606 Welding AWS 5.14 MIG ERNiCr-3 Wire – Herui Detail:

Description

Commercially pure or low-alloy nickel has characteristics that are useful in several fields, notably chemical processing and electronics. Pure Nickel is highly resistant to various reducing chemicals and is unexcelled in resistance to caustic alkalis. Compared with nickel alloys, commercially pure nickel has high electrical and thermal conductivity. It also has a high Curie temperature and good magnetostrictive properties. Annealed nickel has a low hardness and good ductility and malleability. Those attributes, combined with good weldability, make the metal highly fabricable. Pure Nickel has a relatively low work-hardening rate, but it can be cold worked to moderately high strength levels while maintaining ductility.

Common Names

Oxford Alloy 82 FM82 Techalloy 606

Standard

AWS 5.14 Class ERNiCr-3 / ASME SFA 5.14 Class ERNiCr-3 UNS N06082 Werkstoff Nr. 2.4806 ISO SNi6082

Specification

| ERNiCr-3 | Chemical composition.% | |||||||||

| C | Mn | Fe | Si | Cu | Ni | Ti | Cr | Nb | ||

| SNi6082 | NiCr20Mn3Nb | ≤0.1 | 2.5-3.5 | ≤3.0 | ≤0.5 | ≤0.5 | ≥67.0 | ≤0.7 | 18.0-22.0 | 2.0-3.0 |

AWS ERNiCr-3, EN/RN82

Applications

Welding of alloys 600, 601 and alloy 800 to themselves and dissimilar welding of stainless to carbon

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our merchandise and service. At the same time, we do the job actively to do research and improvement for PriceList for Non Magnetic Stainless Steel Scrap Price - Techalloy 606 Welding AWS 5.14 MIG ERNiCr-3 Wire – Herui, The product will supply to all over the world, such as: Qatar, Germany, Vietnam, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!