Special Design for Most Non Magnetic Stainless Steel - Non-magnetic round bar – Herui Detail:

Corrosion resistance requirements: all non-magnetic products can pass the corrosion test specified in practice e of American material test standard a 262.

Non magnetic: relative

Permeability: max. 1.005

Hot spot / field gradient: max. 0.05 μ T

Special treatment inner diameter: roller polishing.(after grinding the roll, a compression layer is formed)

The advantages are as follows: increase corrosion resistance; Increase the surface hardness of the hole to HB400 and the surface finish of the hole to RA ≤ 3.2.

Micron test and inspection of each bar during the production of NMDC, stabilizer and MWD parts: chemical composition; Tensile test; Impact test; Hardness test; Metallographic test (particle size); Corrosion test (according to ASTM A 262 practice E); Ultrasonic testing over the entire length of the bar (according to ASTM a388); Relative magnetic permeability test; Hot spot test, dimensional inspection, etc.

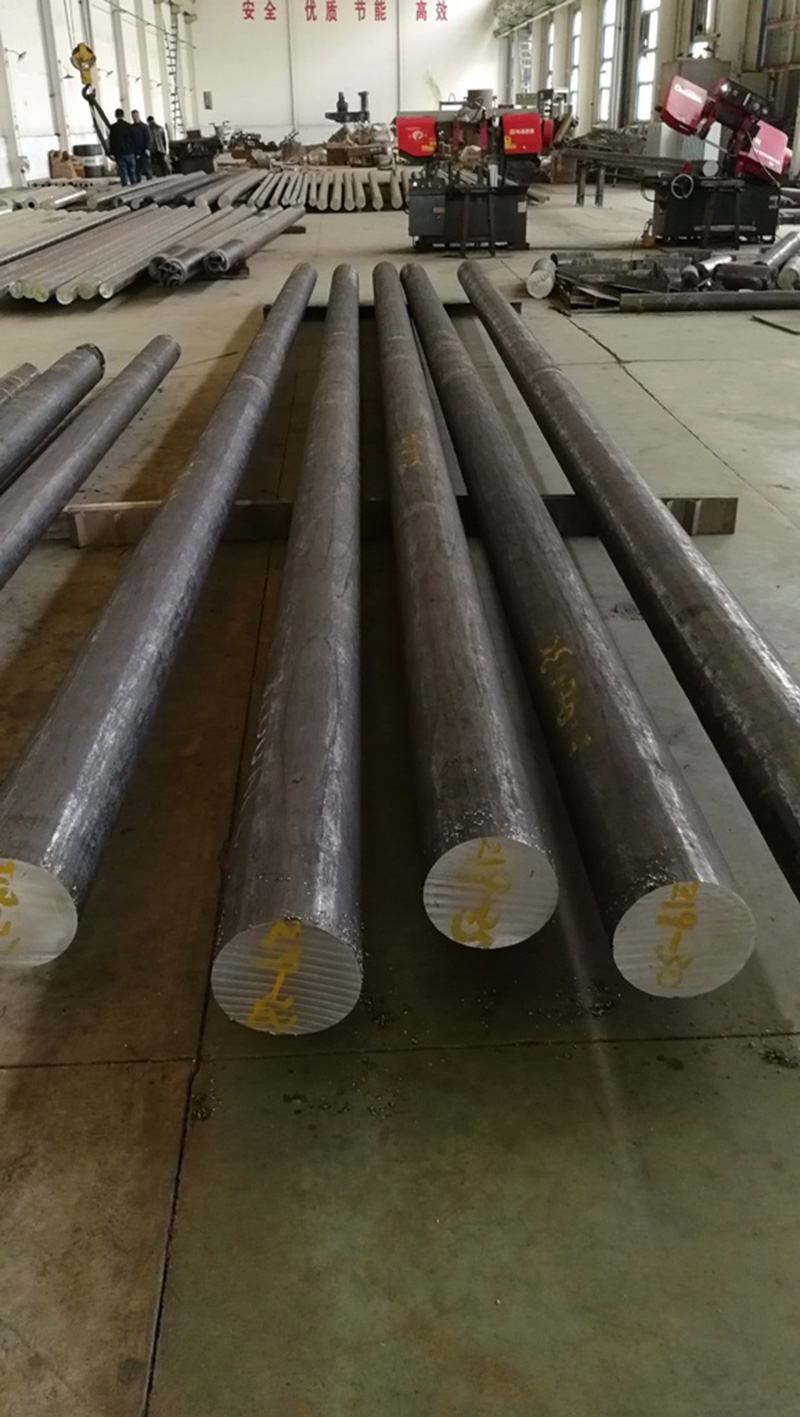

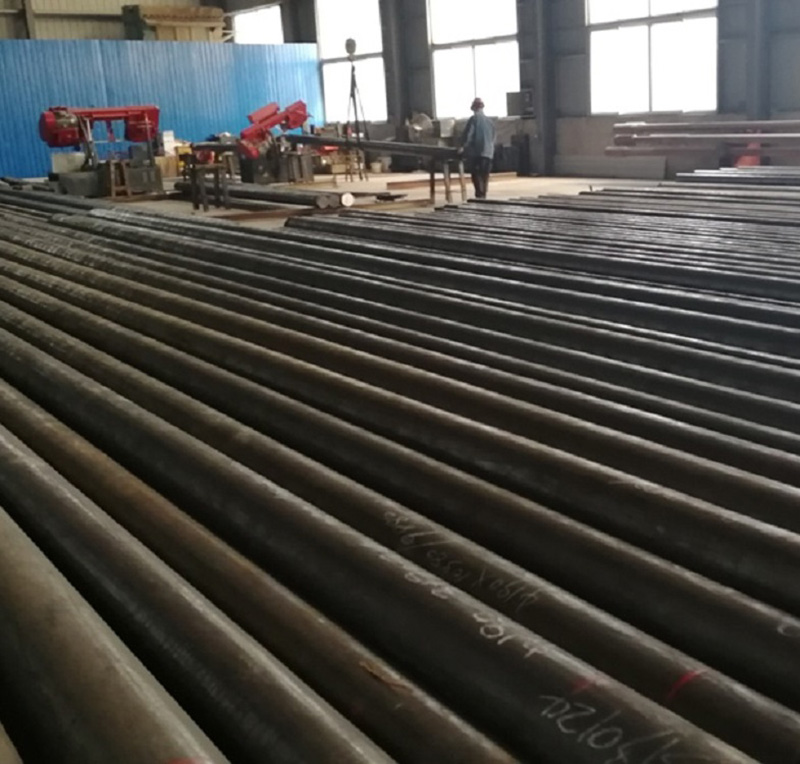

Product detail pictures:

Related Product Guide:

owing to good service, a variety of high quality products, competitive prices and efficient delivery, we enjoy a good reputation among our customers. We are an energetic company with wide market for Special Design for Most Non Magnetic Stainless Steel - Non-magnetic round bar – Herui, The product will supply to all over the world, such as: Turkey, Turkmenistan, United Arab emirates, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

-

Best quality Non Magnetic Stainless Steel Price...

-

New Fashion Design for Monel 405 - Elgiloy all...

-

China Manufacturer for Capillary Tube Cutter -...

-

PriceList for Non Magnetic Steel - Elgiloy all...

-

Fast delivery N08800 - Factoey price oil drill...

-

Bottom price Separates Iron And Steel From Non ...