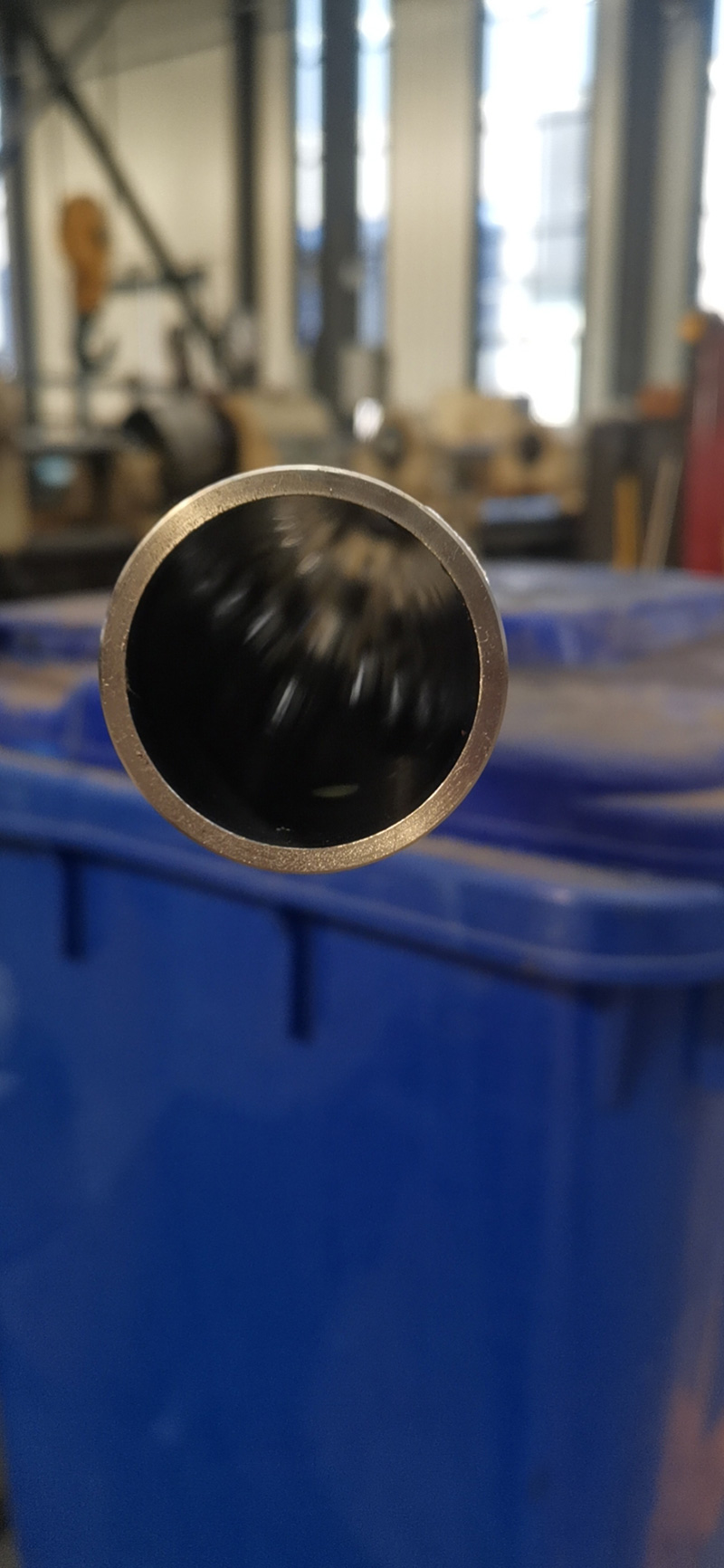

Top Quality High Speed Steel Tool - Non-magnetic pipes – Herui Detail:

Non-magnetic pipes are forged and processed from non-magnetic round bars, which can be further processed into drill pipes, drill collars, suspensions and other products.

Our company have two grades of non-magnetic pipes,P530 and P550. Our materials meet all the performance indicators on the market and reach international standards. For forging, the 1800T precision forging machine is adopted, hot forging first and then warm forging, we strictly control the temperature and deformation of forging to ensure the performance and corrosion resistance of the material.

Our company strictly controls the chemical composition of the material during steelmarking, especially the ratio of C, Cr, Mn, N and other elements, which not only guarantees the high mechanical properties of the material, but also the low magnetic properties. Using electric furnace smelting, then AOE furnace refining.

1. Low permeability, the permeability of the material is within 1.005.

2. Corrosion resistance, 100% passed the corrosion resistance test. If the corrosion performance of the material is not good, it will appear buckle and poor wear resistance during use, which will directly affect the service life.

3. Fatigue test, more than 300,000 times under 65KSI, generally can reach 300,000 times under 80KSI. There are more than 10 million testings continuously under 60KSI.

4. The material is uniform and there is no crack on the surface. After peeling 2mm on one side, the material has no cracks.

Product detail pictures:

Related Product Guide:

Normally customer-oriented, and it's our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for Top Quality High Speed Steel Tool - Non-magnetic pipes – Herui, The product will supply to all over the world, such as: California, Leicester, Israel, We've a skilled sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique merchandise.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.