Well-designed Monel Inconel - Alloy 50 (aka Magnifer 50, Carpenter High Permeability 49, Alloy 47-50) – Herui Detail:

Description

A soft magnetic alloy, consisting of 49% Nickel, balance Iron used where high initial permeability, maximum permeability, and low core loss is needed.

Chemical Composition

| C | P | S | Cu | Mn | Si | Ni | Fe |

| ≤ | |||||||

| 0.03 | 0.020 | 0.020 | 0.20 | 0.30-0.60 | 0.15-0.30 | 49.0-50.5 | Balance |

Characters

High permeability

High magnetic flux density

Good fabrication property

Anti-rust ability

Applications

Small power transformers, micro motors, relays, choke ring and an electromagnetic clutch of core, and magnetic shield of the microphone diaphragm torque motor armature and a conducting magnet.

Equal Grades

1J50(China), 50H(Russia), PB(Japan)

Forms available

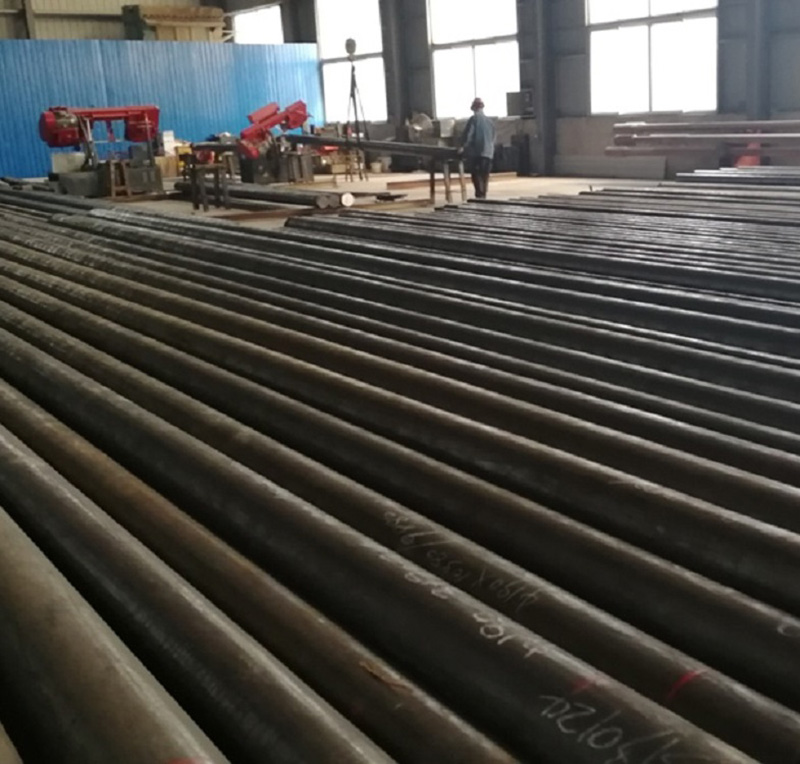

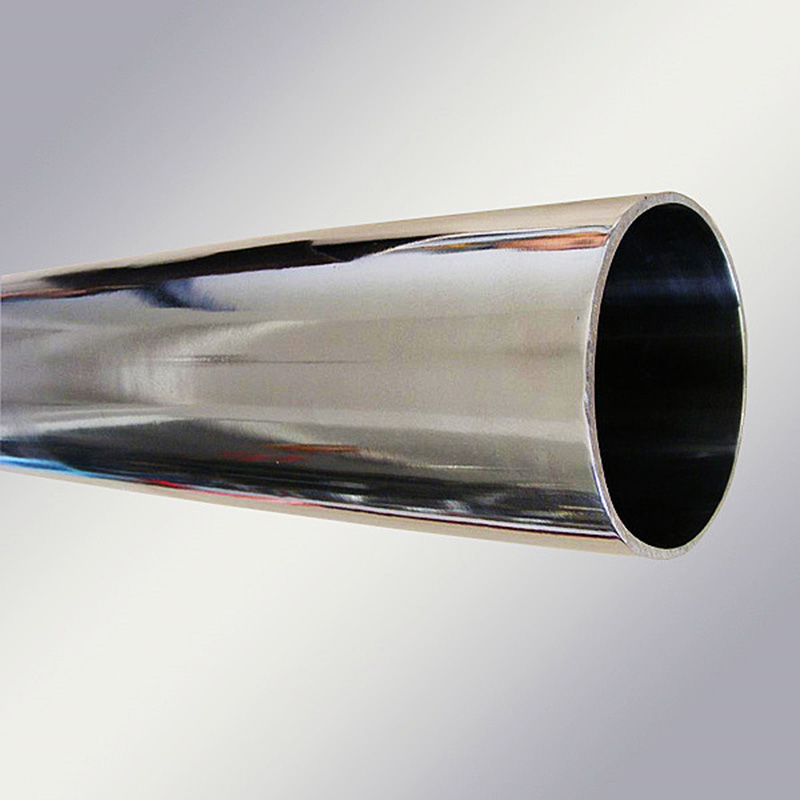

Strip, bar, wire

Product detail pictures:

Related Product Guide:

We will make every effort to be outstanding and perfect, and accelerate our steps for standing in the rank of international top-grade and high-tech enterprises for Well-designed Monel Inconel - Alloy 50 (aka Magnifer 50, Carpenter High Permeability 49, Alloy 47-50) – Herui, The product will supply to all over the world, such as: Serbia, Gabon, Naples, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.