Factory directly supply Non Magnetic Steel Plate - Alloy 52 (aka Pernifer 50, NILO 50, Glass Seal 52) – Herui Detail:

Description

A controlled expansion alloy, consisting of 51% Nickel, balance Iron, used in a wide variety of electronic applications, especially for glass seals. Alloy 52 is a nickel iron alloy whose coefficient of expansion closely mirrors soft glass. Applications for this product include magnetic reed switches and seals that need controlled linear expansion to approximately 525 °C.

Alloy 52 Basic Chemical Composition (Weight %)

| Ni | 50.50 |

| Cr | 0.10 max |

| Mn | 0.60 max |

| Si | 0.30 max |

| C | 0.05 max |

| Al | 0.10 max |

| Mg | 0.50 max |

| P | 0.025 max |

| S | 0.025 max |

| Fe | Balance |

Typical Mechanical Properties

|

Alloy 52 |

Annealed |

As Rolled |

|

Ultimate Tensile Strength (PSI) |

75,000 |

130,000 |

|

Yield Strength (PSI) |

30,000 |

125,000 |

|

Elongation |

30% |

1% |

|

Modulus of Elasticity (PSI) |

24 x 10e6 |

|

|

Poisson’s Ratio |

0.29 |

|

Typical Physical Properties

Density 0.300 lbs/cu in

Melting Point 1425° C

Electrical Resistivity @ RT 43 Microhm-cm

Temp. Coefficient Resistivity 2900 PPM/°C

(20 to 100° C)

Thermal Expansion Coefficient 10.0 x 10e-6/°C

(30 to 400° C)

Applications

Glass to metal seals for electronic tubes, automotive and industrial lamps, and specialty hermetic devices.

Available Forms

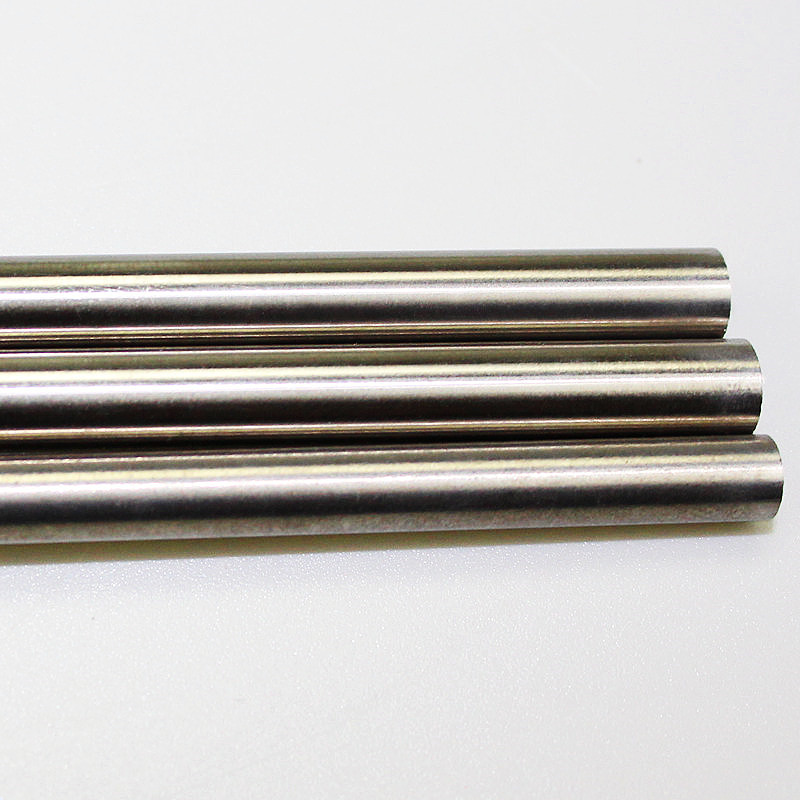

Alloy 52 is available in Strip, Sheet, Plate and Wire.

Product detail pictures:

Related Product Guide:

During the past few years, our business absorbed and digested state-of-the-art technologies the two at home and abroad. Meanwhile, our firm staffs a group of experts devoted to your development of Factory directly supply Non Magnetic Steel Plate - Alloy 52 (aka Pernifer 50, NILO 50, Glass Seal 52) – Herui, The product will supply to all over the world, such as: Iran, Pakistan, Croatia, Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact me. We are looking forward to forming successful business relationship with new clients around the world.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.

-

Good quality Non Magnetic Steel Types - Elgilo...

-

High reputation M2 Steel Price - Factory price...

-

factory customized High Speed Steel Step Bit -...

-

Factory Cheap Solid High Speed Tooling Lathe -...

-

Factory directly supply Inconel 718 Round Bar -...

-

High definition Oil Drilling Tools Series - El...