100% Original Steel Non Magnetic Temperature - Non magnetic steel – Herui Detail:

Effect

The magnetic drill belongs to oil and gas exploration tools to explore the well. During the drilling process, the drill often has magnetic, magnetic fields, affecting the magnetic measuring instrument, and cannot obtain the correct wellbore track measuring information data, and the magnetic environment can be implemented with a non-magnetic diamond, and has the characteristics of drill in the drilling. A considerable number of non-magnetic drill products abroad are included in the API standard in 1990. my country has developed SY / T 5145-86 “No magnetic drill” standard based on foreign products and product samples.

Working Principle

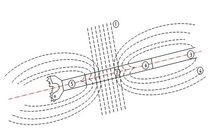

Schematic diagram of the function of the magnetic drill

1 geomagnetic field; 2 magnetic measuring instrument; 3 steel drill; 4 interfere with magnetic field; 5 drill joint; 6 no magnetic drill

The interference magnetic field line up and down without magnetic drill has no effect on the measurement instrument site, so that the magnetic diamond creates a non-magnetic environment for the magnetic measurement instrument, ensuring the data measured by the magnetic measurement instrument as the real land magnetic field information.

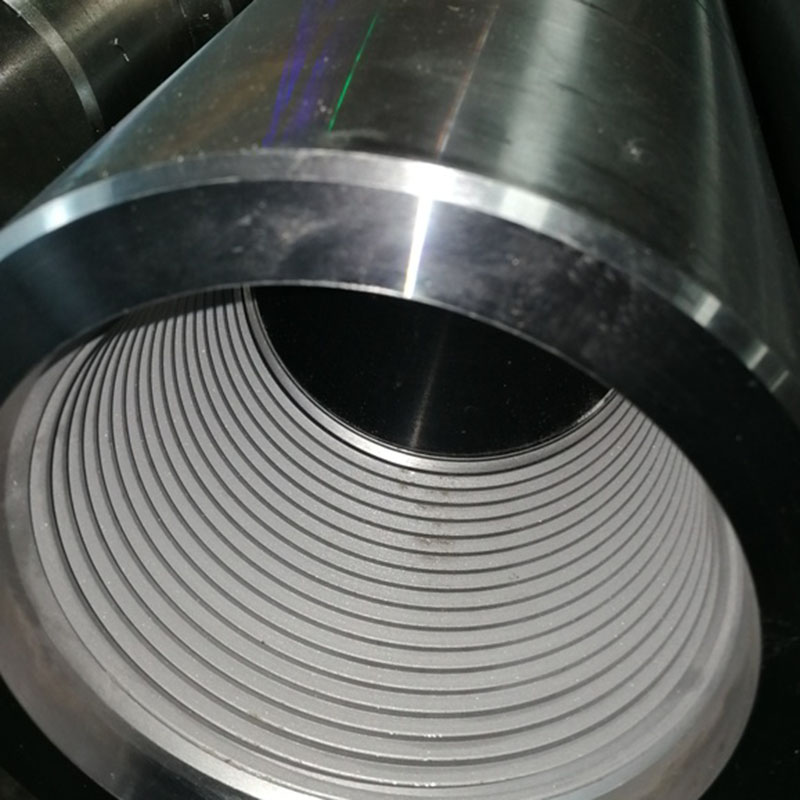

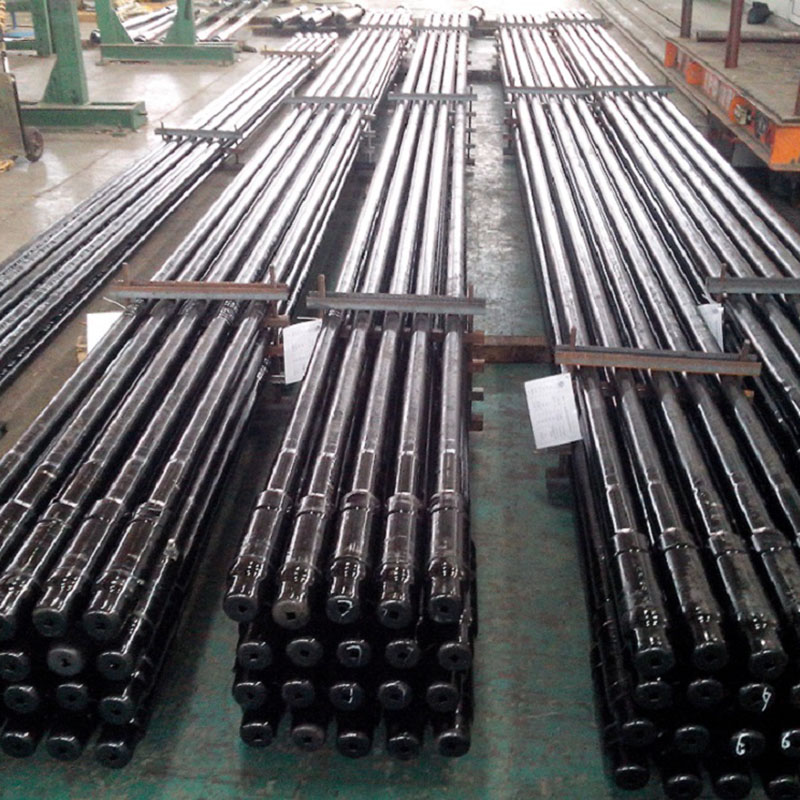

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for 100% Original Steel Non Magnetic Temperature - Non magnetic steel – Herui, The product will supply to all over the world, such as: UK, Brasilia, Swedish, If you have any requests, pls email Us with your detailed demands, we will give you the most wholesale Competitive Price with the Super Quality and the Unbeatable First-class Service ! We can give you the most competitive prices and high quality, because we are much more PROFESSIONAL! So please do not hesitate to contact us.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!