18 Years Factory Hss Coiled Material - NIMONIC 80A – Herui Detail:

Description

NIMONIC alloy 80A (UNS N07080/W. Nr. 2.4952 & 2.4631) is a wrought, age-hardenable nickel-chromium alloy, strengthened by additions of titanium, aluminum and carbon, developed for service at temperatures up to 815°C (1500°F). It is produced by high-frequency melting and casting in air for forms to be extruded. Electroslag refined material is used for forms to be forged. Vacuum refined versions are also available. NIMONIC alloy 80A is currently used for gas turbine components (blades, rings and discs), bolts, nuclear boiler tube supports, die casting inserts and cores, and for automobile exhaust valves.

Limiting chemical composition, % by weight

| Carbon | 0.10 max. |

| Chromium | 18.0-21.0 |

| Silicon | 1.0 max |

| Copper | 0.2 max. |

| Iron | 3.0 max. |

| Manganese | 1.0 max. |

| Titanium | 1.8-2.7 |

| Aluminum | 1.0-1.8 |

| Cobalt | 2.0 max. |

| Boron | 0.008 max. |

| Zirconium | 0.15 max. |

| Lead | 0.0025 max. |

| Sulfur | 0.015 max. |

| Nickel | Balance |

Application

Nimonic 80A could be used for gas turbine components such as blades, rings and plates, etc. Other applications include bolts used in temperature and stress limit, the combustion engine exhaust valve and other high strength parts. For example, the nuclear boiler tube bracket, etc. The alloy is also suitable for high temperature springs, especially in the condition of continuous stress under the working conditions.

Equal grades

GH4080A(GH80A), W.Nr 2.4952, UNS N07080, Nicrofer 7020 Ti,NiCr20TiAl

Available Product Forms

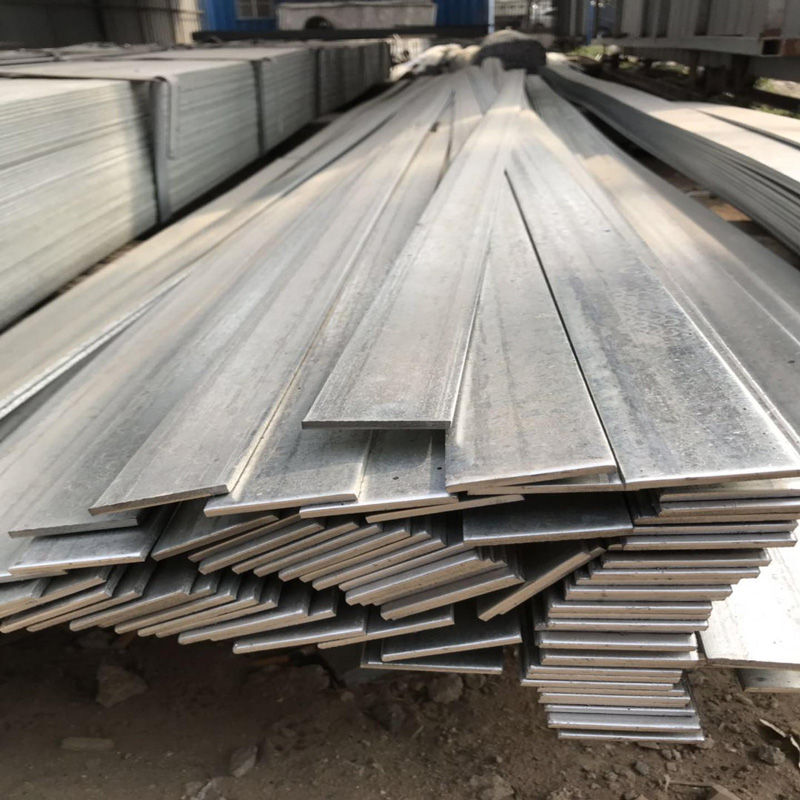

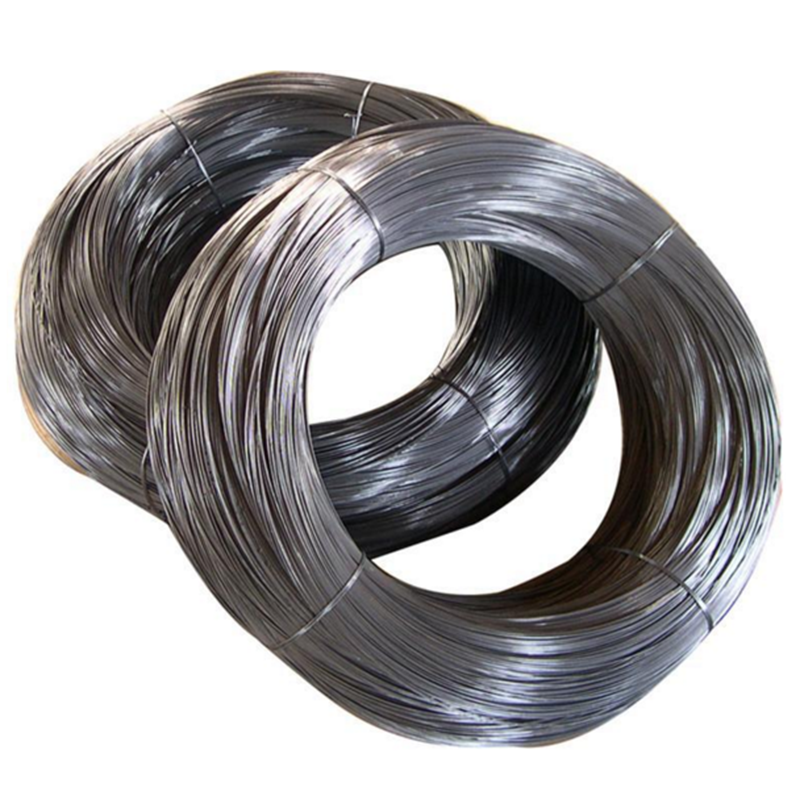

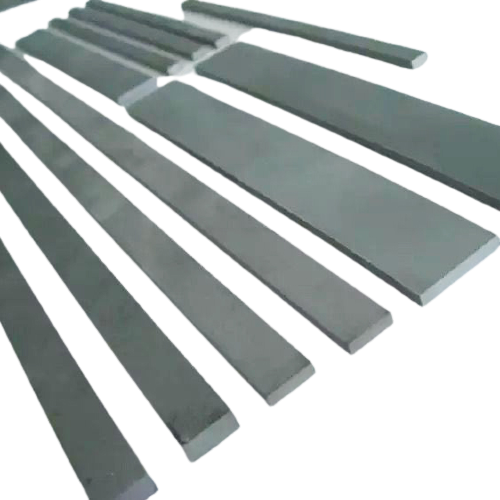

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

Product detail pictures:

Related Product Guide:

We've been commitment to offer the competitive rate ,outstanding merchandise good quality, too as fast delivery for 18 Years Factory Hss Coiled Material - NIMONIC 80A – Herui, The product will supply to all over the world, such as: Mexico, Oslo, United Arab emirates, We mainly sell in wholesale, with the most popular and easy ways of making payment, which are paying via Money Gram, Western Union, Bank Transfer and Paypal. For any further talk, just feel free to contact our salesmen, who are really good and knowledgeable about our prodcuts.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.

-

2021 Good Quality What Makes Stainless Steel No...

-

China Cheap price Non Magnetic Casing - No mag...

-

High Quality for Quartz Capillary Tube - Elgil...

-

Wholesale Dealers of Hss Tool Material - Super...

-

China Supplier Glass Capillary Tube - Elgiloy ...

-

2021 High quality High Speed Steel Plate - hig...