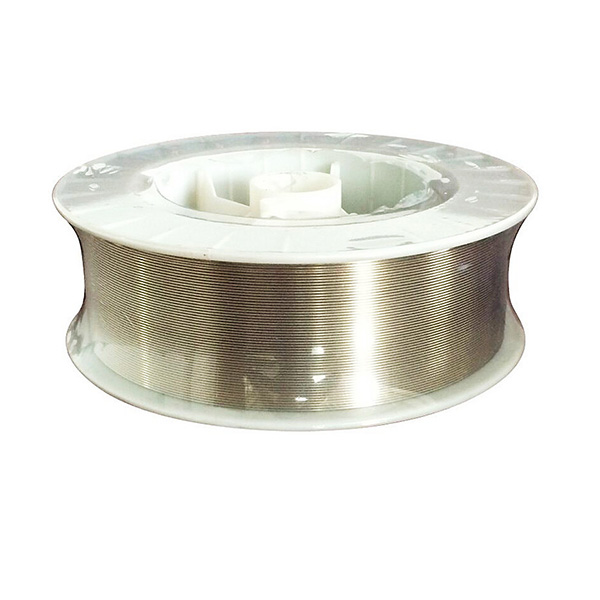

China Cheap price Inconel Filler Wire - Inconel 625 – Herui Detail:

Description

IINCONEL nickel-chromium alloy 625 (UNS N06625 / W. Nr. 2.4856 / GH3625 / NS336) is used for its high strength, excellent fabricability (including joining), and outstanding corrosion resistance. Service temperatures range from cryogenic to 1800°F (982°C).

Limiting Chemical Composition, %

| Nickel | 58.0 min. |

| Chromium | 20.0-23.0 |

| Iron | 5.0 max. |

| Molybdenum | 8.0-10.0 |

| Niobium (plus Tantalum) | 3.15-4.15 |

| Carbon | 0.10 max. |

| Manganese | 0.50 max. |

| Silicon | 0.50 max. |

| Phosphorus | 0.015 max. |

| Sulfur | 0.015 max. |

| Aluminum | 0.40 max. |

| Titanium | 0.40 max. |

| Cobalt | 1.0 max. |

Application

Aircraft ducting systems

Aerospace

Jet engine exhaust systems

Engine thrust-reverser systems

Specialized seawater equipment

Chemical process equipment

Forms available

Plate, sheet, strip, wire, rod, bar, forging, pipe, tube, fitting, powder

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for China Cheap price Inconel Filler Wire - Inconel 625 – Herui, The product will supply to all over the world, such as: Karachi, Singapore, India, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.