Competitive Price for High Speed Tool Factory - Non-magnetic plate – Herui Detail:

Non-magnetic plate is a kind of high-strength austenitic non-magnetic die steel, which can maintain stable austenite in various states, they have very low permeability, high-temperature strength,hardness, and high wear resistance. But its mechanical processing performance is poor, so they need high temperature annealing to change the particle size and distribution of carbides. The use of gas nitrocarburizing heat treatment can further improve the surface hardness and wear resistance, thereby increasing the service life of the mold. The factory hardness of 7MN15CR2AL3V2WMO non-magnetic steel is divided into annealed state and pre-hardened state; the annealed state hardness is 28-30HRC, and the pre-hardened state hardness is 40-45HRC. The surface treatment hardness of 7MN15 is 950-1100HV. Compared with high manganese austenitic steel, the steel has a service life of about 3 times longer than that of high manganese austenitic steel. It is suitable for non-magnetic cold work molds and hot work molds in high temperature environments. Due to the cold work hardening phenomenon of high manganese steel, cutting processing is more difficult. The high temperature annealing process can change the size, shape and distribution of carbide particles, thereby significantly improving the cutting performance of steel. The gas soft oxidation process is adopted to further improve the surface hardness of the steel, increase the wear resistance, and significantly increase the service life of the parts. The steel is suitable for manufacturing non-magnetic molds, non-magnetic bearings and other structural parts that require no magnetic induction in a strong magnetic field. In addition, because this steel has good high-temperature strength and hardness, it can also be used to make hot work molds that are used below 700°C to 800°C.

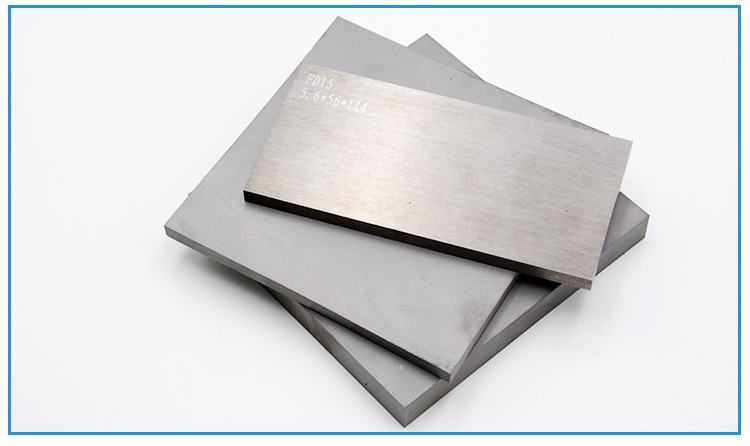

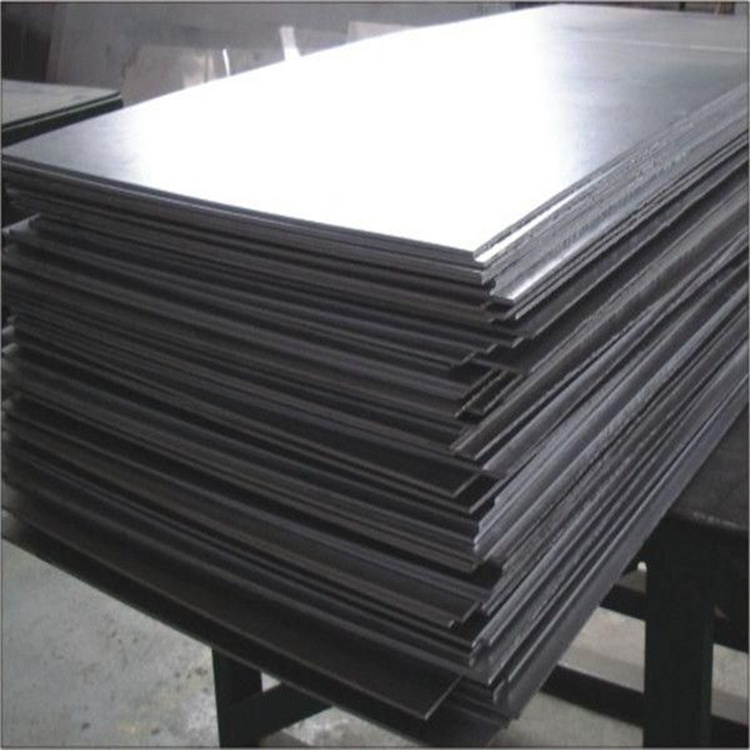

Product detail pictures:

Related Product Guide:

We emphasize advancement and introduce new products into the market each year for Competitive Price for High Speed Tool Factory - Non-magnetic plate – Herui, The product will supply to all over the world, such as: South Korea, Thailand, Islamabad, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part solutions. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

-

8 Year Exporter Borosilicate Glass Capillaries ...

-

OEM/ODM China 4341 Steel - Elgiloy alloy (Co40...

-

Top Suppliers 304 Ss Magnetic - High Quality G...

-

Best Price on Hss Bar Stock - No magnetic cros...

-

New Delivery for High Speed Steel Supplier - E...

-

8 Year Exporter At What Temp Does Steel Become ...