Excellent quality Non Magnetic Temperature Steel - Made In China Non Magnetic Steel Plate No magnetic Drilling Tools – Herui Detail:

- Condition:

-

New

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- Local Service Location:

-

None

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

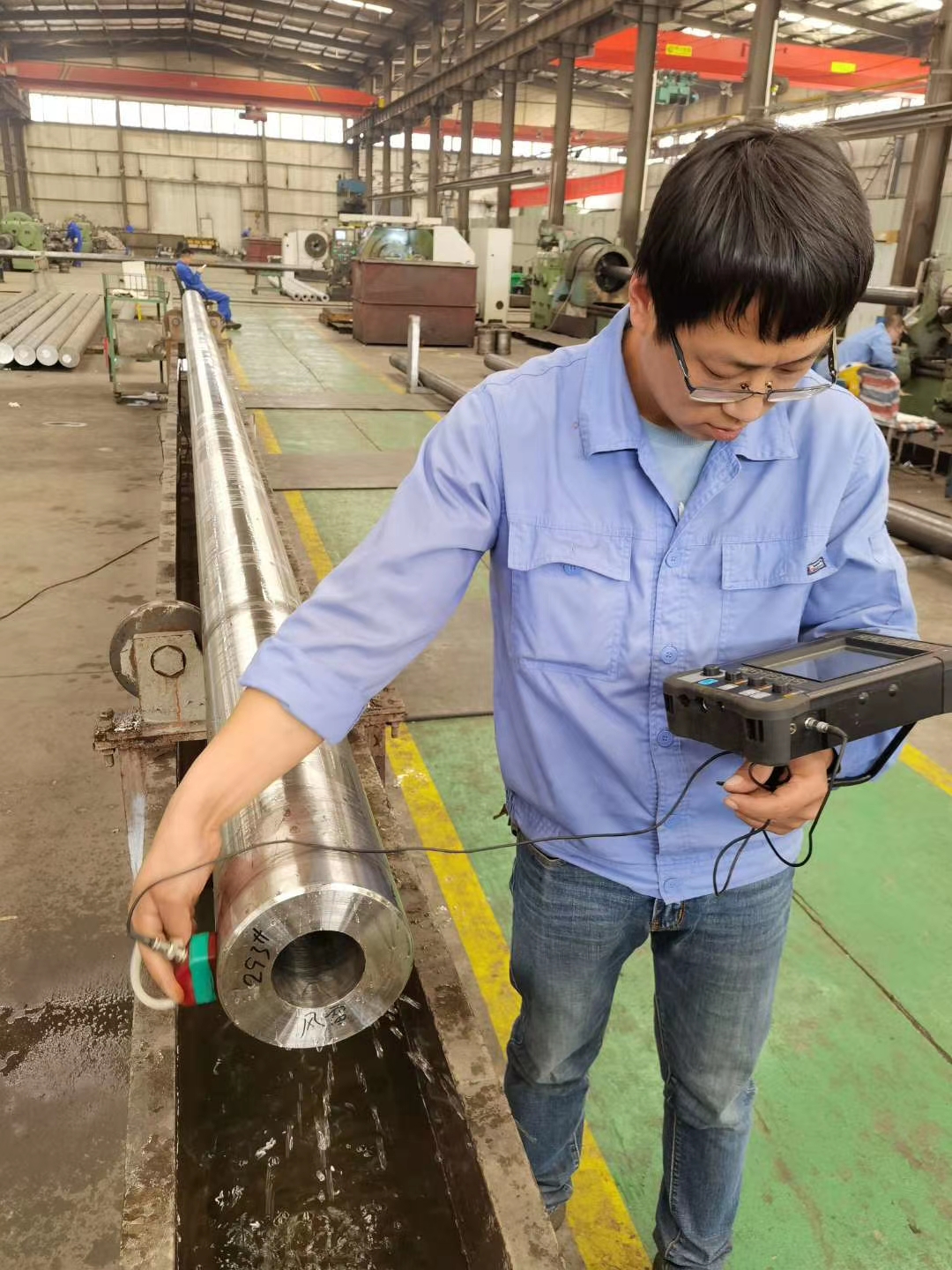

- Machinery Test Report:

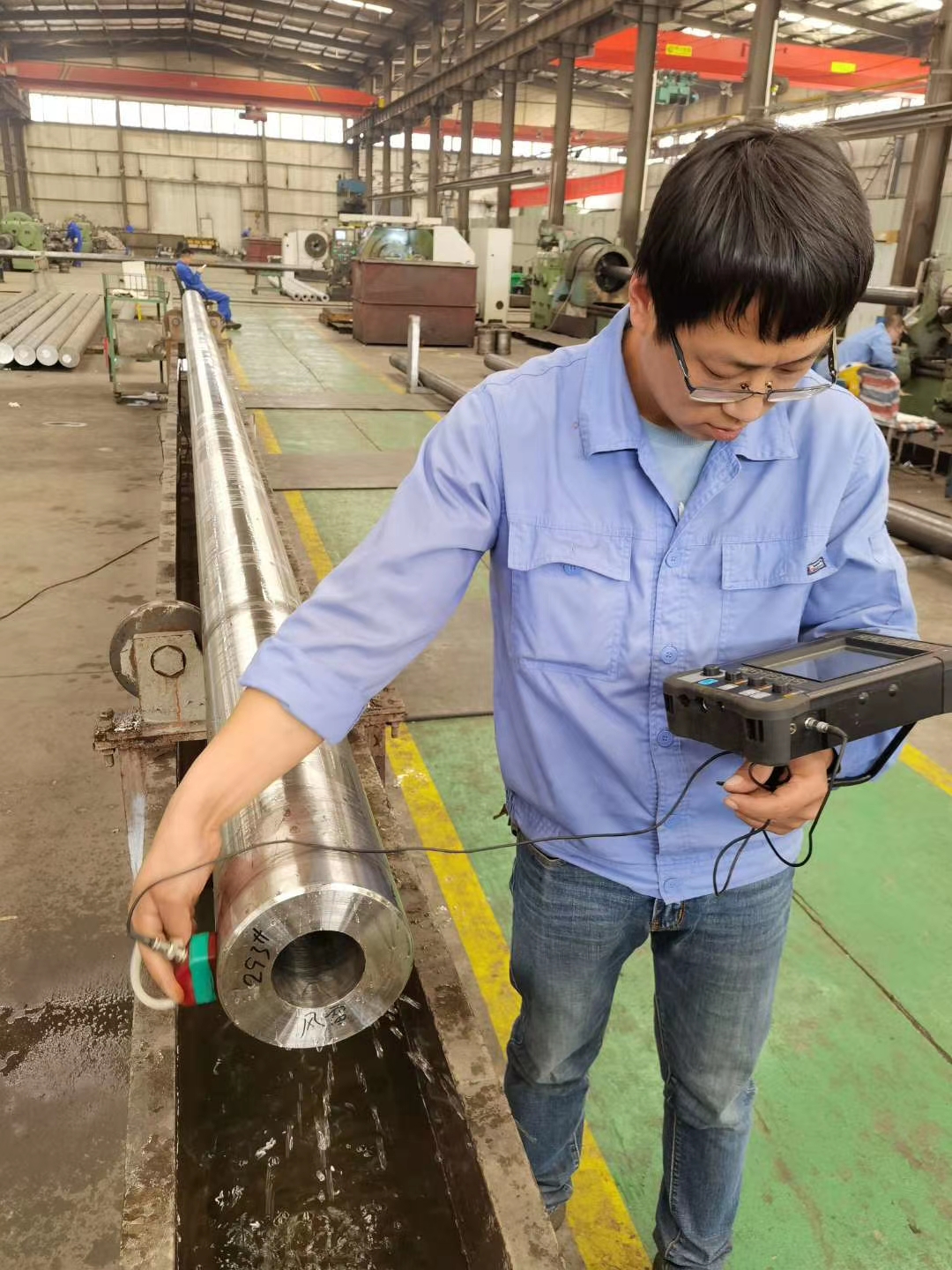

-

Provided

- Marketing Type:

-

New Product 2020

- Place of Origin:

-

Jiangsu, China

- Brand Name:

-

HR

- Type:

-

Drill Collar, Non magnetic steel

- Machine Type:

-

Drilling Equipment

- Certification:

-

API

- Use:

-

Well Drilling

- Product name:

-

Non-magnetic drill collar

- Usage:

-

oil exploitation

- Appearance:

-

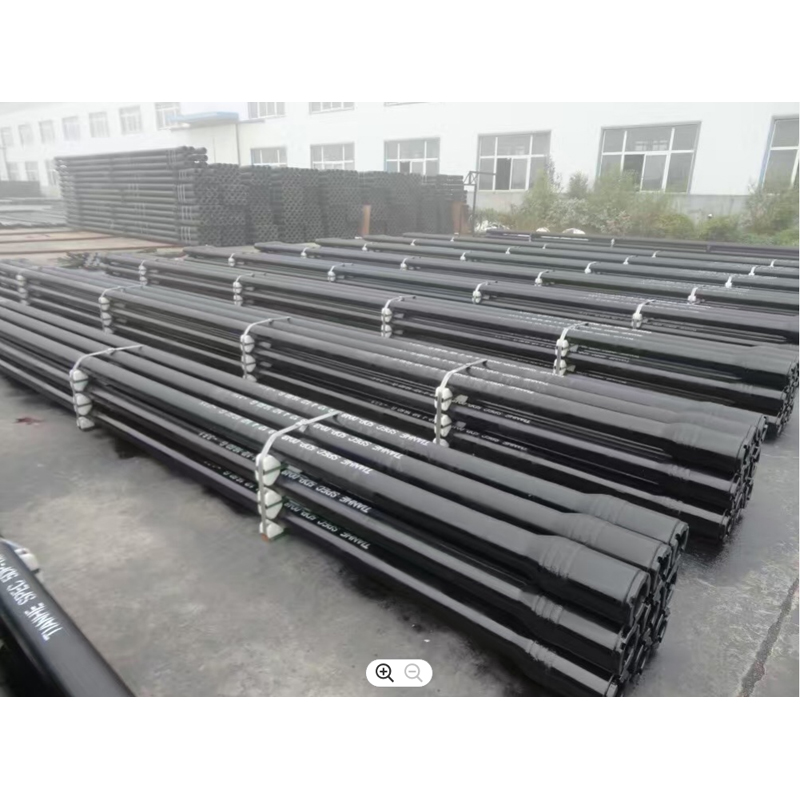

Round column

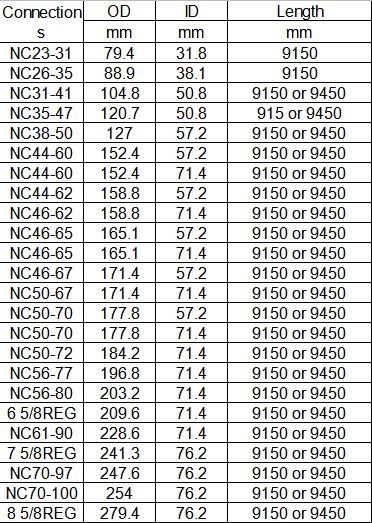

- Size:

-

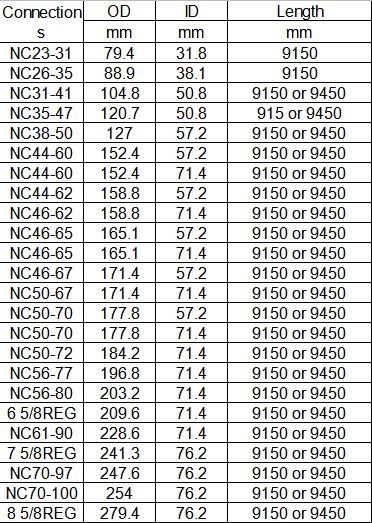

3 1/2″, 4 1/8″ , 4 3/4 “, 5″ ,6 1/2″, 6 3/4″, 7″ , 8″ 9″ etc

- Standard:

-

API Spec 7-1

- Main Market:

-

Mn Cr Ni

- Advantage:

-

Quality. We have sales staff in Europe

- Package:

-

Plastic wrap

- Purity:

-

C Si Mn P S Cr Ni Mo Cu N

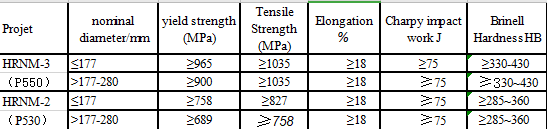

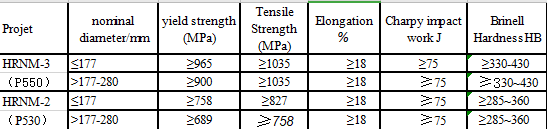

* Hrnm-2 is similar to P530 standard material

Hrnm-3 is similar to P550 standard material

Agile, innovative and quality-oriented company aiming at long-term partnership

Located in Danyang, Jiangsu province, a dynamic area for special steel

Relying on a network of qualified partners all specialized in special steel

Offering a short lead-time serviceTwo shareholders have a strong background in special steel more than 25 years experience

anti-collision ring.There should be at least two iron frames in each group of two or three for fixing

A: You can contact us by email about your order details, or place order on line.

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank), L/C, D/P, Western Union are the most usual ways we are using. If you want to use other way, please tell me, we can discuss.What’s the order procedure?

A: First we discuss order details, production details by email or TM. Then we issue you an PI for your confirmation. You will be requested to do pr-epaid full payment or deposit before we go into production. After we get the deposit, we start to process the order. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

How do you take care when your clients received defective products?

A: replacement. If there are some defective items, we usually credit to our customer or replace in next shipment.

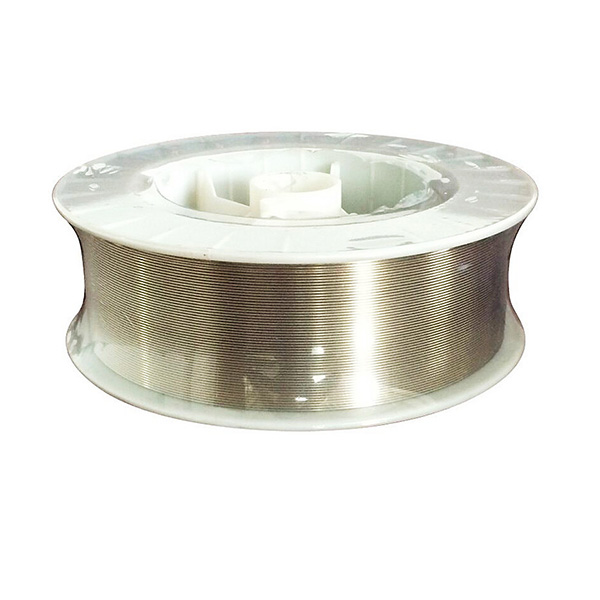

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for Excellent quality Non Magnetic Temperature Steel - Made In China Non Magnetic Steel Plate No magnetic Drilling Tools – Herui, The product will supply to all over the world, such as: United States, Finland, Eindhoven, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve products and provide more comprehensive services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

-

Hot New Products Hss 1.3343 - API No magnetic ...

-

China Cheap price Non Magnetic Stainless Steel ...

-

Special Design for Capillary Tube Chemistry - ...

-

China wholesale High Speed Steel Rod - HSS mat...

-

Factory wholesale Skh51 Steel - Techalloy 606 ...

-

Manufacturer of Ngo Electrical Steel - Hymu80 ...