Factory directly High Speed Steel Lathe Tools - Factory wholesale Kovar Invar 36 4J50 Material Nickel Alloy Pipe – Herui Detail:

- Place of Origin:

-

Jiangsu, China

- Type:

-

Nickel Pipe

- Application:

-

precise instrument

- Grade:

-

kovar invar

- Ni (Min):

-

As Scheduled

- Resistance (μΩ.m):

-

0.45-0.48

- Powder Or Not:

-

Not Powder

- Ultimate Strength (≥ MPa):

-

As Scheduled

- Elongation (≥ %):

-

As Scheduled

- Model Number:

-

Nickel Pipe

- Brand Name:

-

HeRui

- Product name:

-

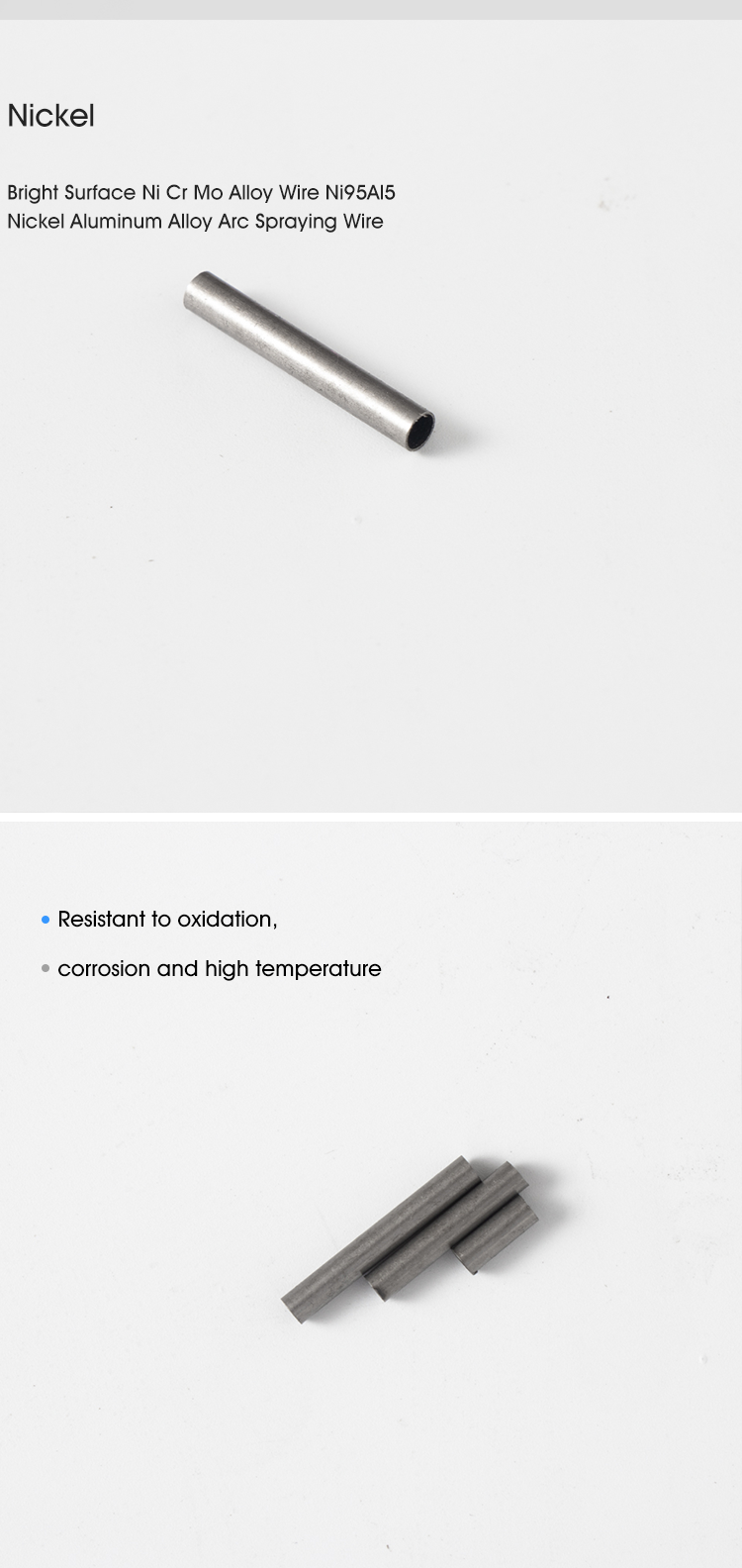

Kovar Invar 36 4J50 Material Nickel Alloy Pipe

- Standard:

-

As Scheduled

- Surface:

-

Bright

- Delivery Time:

-

20 Days

- Shape:

-

Pipe

- MOQ:

-

50kg

|

Limiting Chemical Composition, %

|

||

|

Nickel

|

58.0 min

|

|

|

Chromium

|

20.0-23.0

|

|

|

Iron

|

5.0 max

|

|

|

Molybdenum

|

8.0-10.0

|

|

|

Niobium (plus Tantalum)

|

3.15-4.15

|

|

|

Carbon

|

0.10 max

|

|

|

Manganese

|

0.50 max

|

|

|

Silicon

|

0.50 max

|

|

|

Phosphorus

|

0.015 max

|

|

|

Sulfur

|

0.015 max

|

|

|

Aluminum

|

0.40 max

|

|

|

Titanium

|

0.40 max

|

|

|

Cobalt

|

1.0 max

|

|

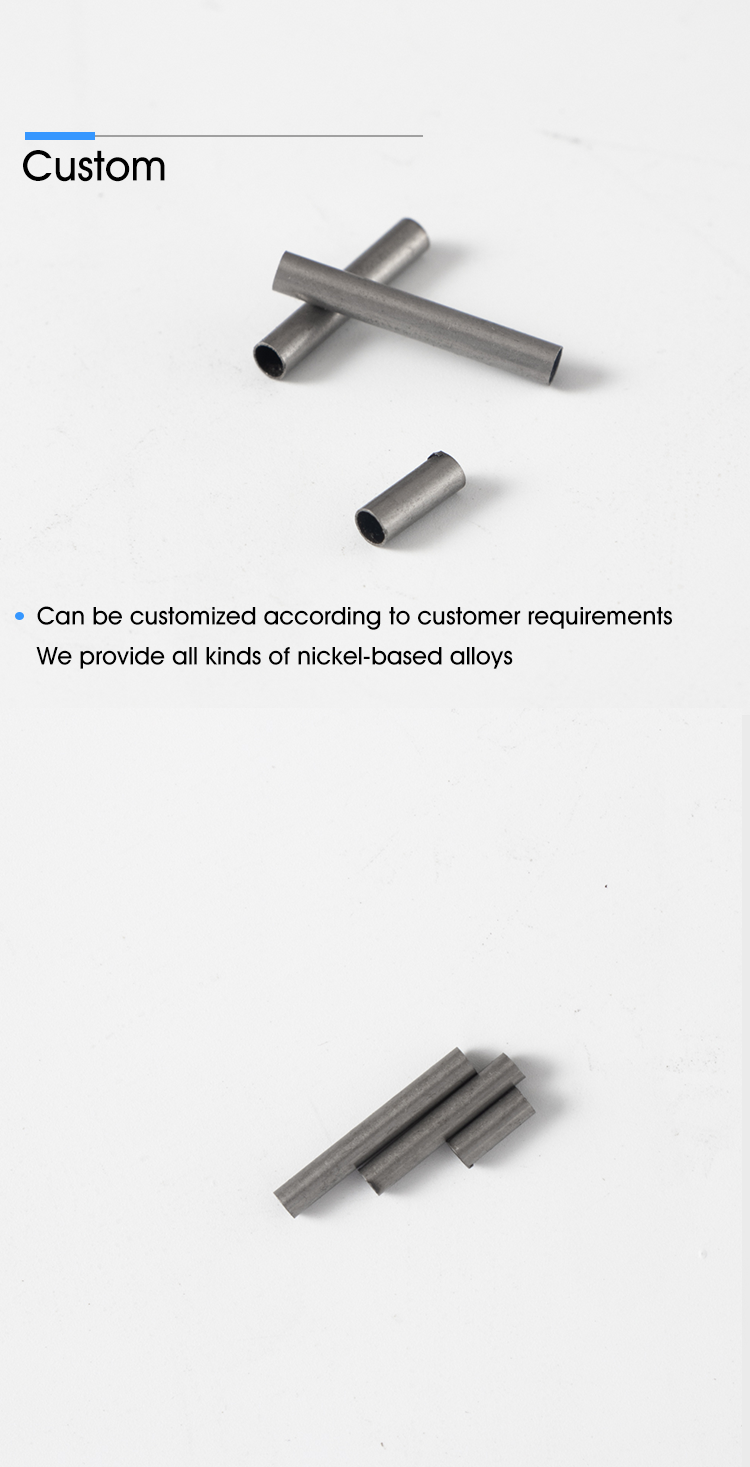

Product detail pictures:

Related Product Guide:

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for Factory directly High Speed Steel Lathe Tools - Factory wholesale Kovar Invar 36 4J50 Material Nickel Alloy Pipe – Herui, The product will supply to all over the world, such as: UK, Jeddah, Jersey, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

-

Reasonable price for Alloy K500 - High quality...

-

Factory directly supply High Speed Steel Tool B...

-

Chinese Professional Blue Capillary Tube - HeR...

-

Top Quality Coiled Material - API No magnetic ...

-

Super Purchasing for Non Heparinized Capillary ...

-

High Quality Hss Tool Steel - API No magnetic ...