Factory Free sample M2 Tool Steel Heat Treatment - Factory Direct Supply High Quality Seamless Pure Nickel Pipe Ni 200 Nickel Tube – Herui Detail:

- Place of Origin:

-

Jiangsu, China

- Type:

-

Nickel Pipe

- Application:

-

precise instrument

- Grade:

-

kovar invar

- Ni (Min):

-

As Scheduled

- Resistance (μΩ.m):

-

0.45-0.48

- Powder Or Not:

-

Not Powder

- Ultimate Strength (≥ MPa):

-

As Scheduled

- Elongation (≥ %):

-

As Scheduled

- Model Number:

-

Nickel Pipe

- Brand Name:

-

HeRui

- Product name:

-

Seamless Pure Nickel Pipe Ni 200 Nickel Tube

- Standard:

-

As Scheduled

- Surface:

-

Bright

- Delivery Time:

-

20 Days

- Shape:

-

Pipe

- MOQ:

-

50kg

|

Limiting Chemical Composition, %

|

||

|

Nickel

|

58.0 min

|

|

|

Chromium

|

20.0-23.0

|

|

|

Iron

|

5.0 max

|

|

|

Molybdenum

|

8.0-10.0

|

|

|

Niobium (plus Tantalum)

|

3.15-4.15

|

|

|

Carbon

|

0.10 max

|

|

|

Manganese

|

0.50 max

|

|

|

Silicon

|

0.50 max

|

|

|

Phosphorus

|

0.015 max

|

|

|

Sulfur

|

0.015 max

|

|

|

Aluminum

|

0.40 max

|

|

|

Titanium

|

0.40 max

|

|

|

Cobalt

|

1.0 max

|

|

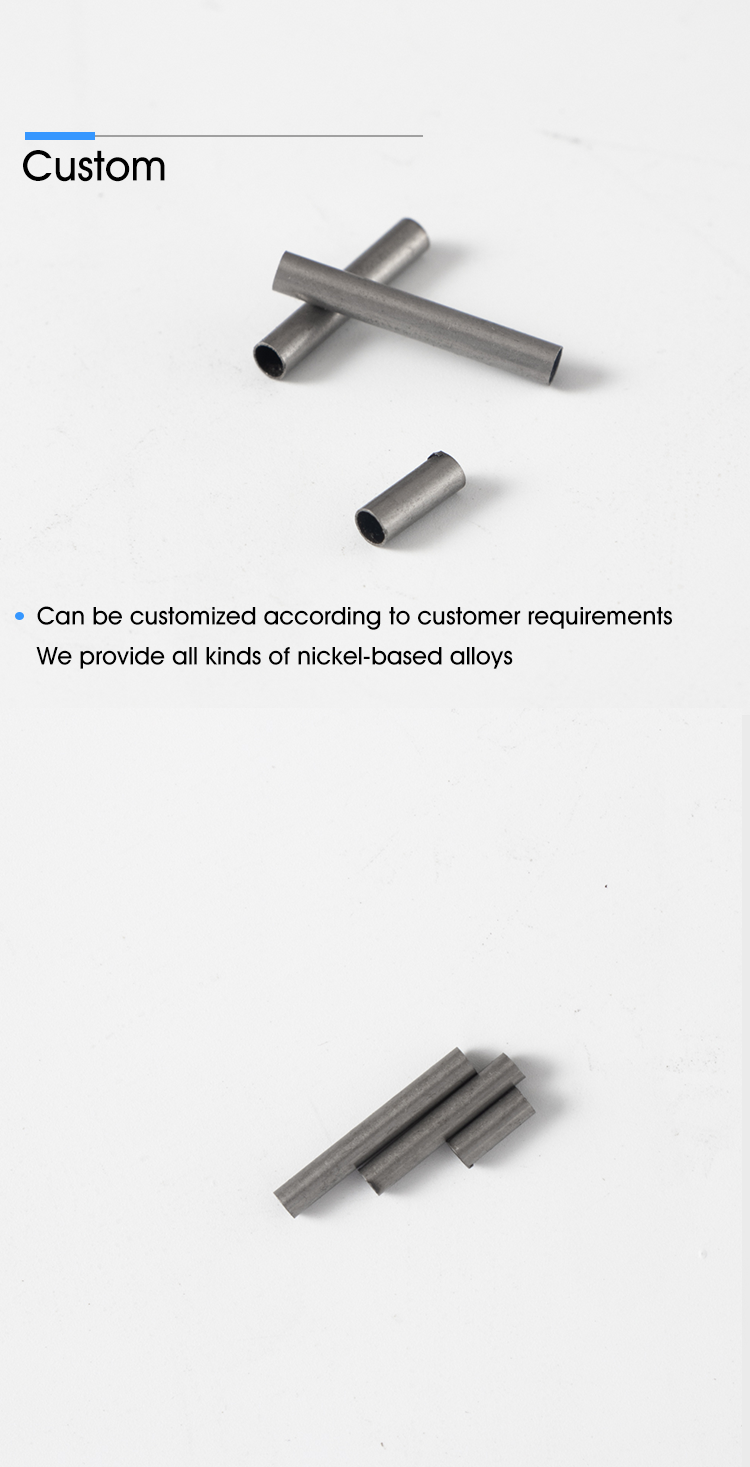

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Factory Free sample M2 Tool Steel Heat Treatment - Factory Direct Supply High Quality Seamless Pure Nickel Pipe Ni 200 Nickel Tube – Herui, The product will supply to all over the world, such as: Salt Lake City, Poland, United States, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specifications. Ideal efforts will probably be produced to provide you the most beneficial service and solutions. Should you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We'll constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Please feel absolutely free to speak to us for organization. nd we believe we will share the best trading practical experience with all our merchants.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!