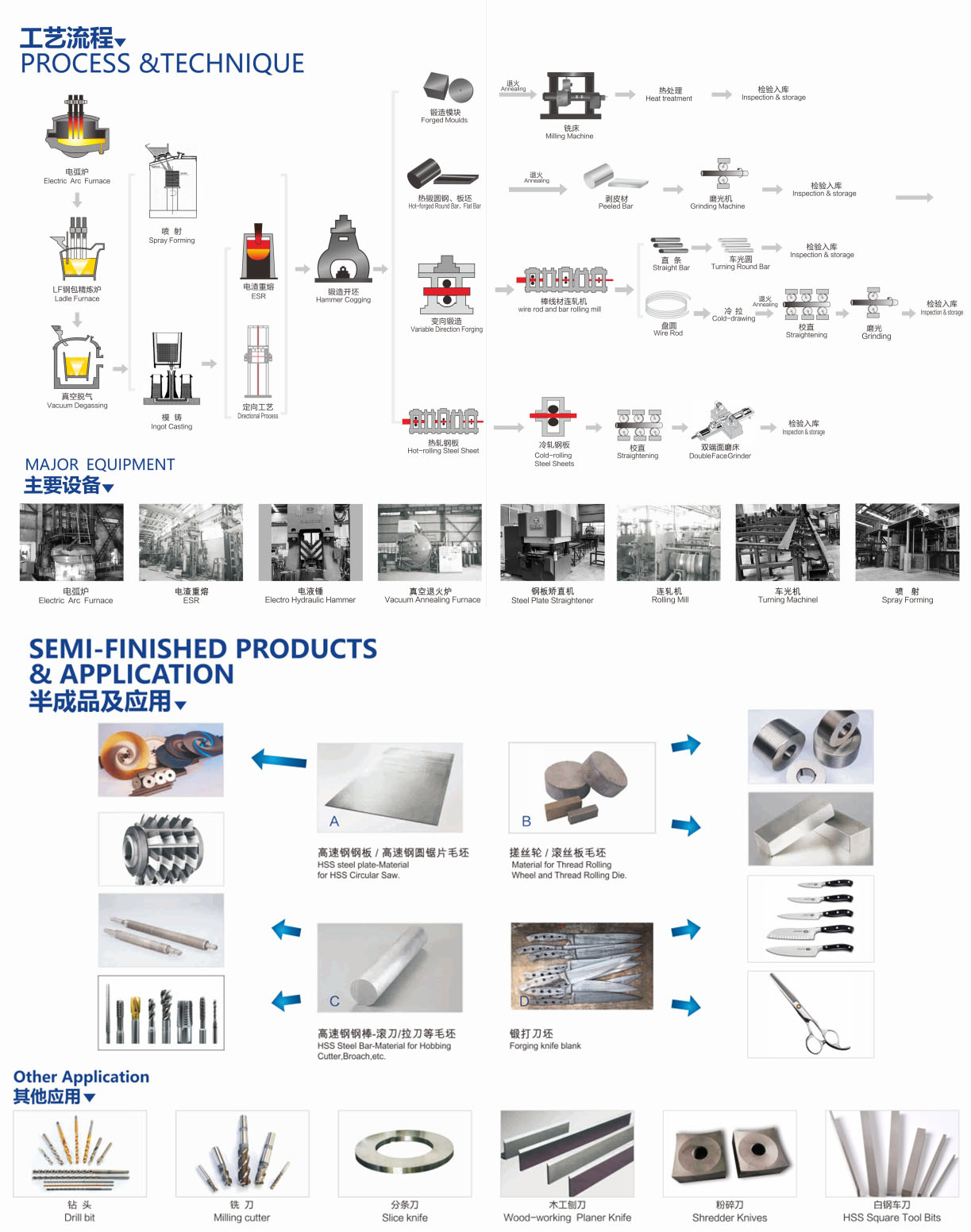

Factory Supply Solid High Speed Tooling - Directional Powder HSS – Herui Detail:

| tional Powder HSS | Similar Grade | ||||

| GB | JIS | ASTM | ERASTEEL | DIN | |

| M36 | ASP2030 | ||||

| M32 | ASP2023 | ||||

| tional Powder HSS | Chemical composition | |||||||

| C | Si | Mn | Cr | W | Mo | V | Co | |

| 1.29 | 0.4 | 0.3 | 4 | 6.5 | 5 | 3 | 8.3 | |

| 1.18 | 0.4 | 0.3 | 4 | 5 | 6 | 2.7 | ||

ZHENJIANG HERUI BUSINESS BRIDGE IMP&EXP Co., Ltd.

A new partner for High speed steel and Non magnetic steel

Agile, innovative and quality-oriented company aiming at long-term partnership

Located in Danyang, Jiangsu province, a dynamic area for special steel

Relying on a network of qualified partners all specialized in special steel

Offering a short lead-time service

Two shareholders have a strong background in special steelmore than 25 years experience.

Main Prodcuts:

1/ High speed steel

grade : M2 ,M35, W4 ,W9

Drawn bar Ø2-16mm

Ground barØ 5-15mm

Peeled or turned round bar Ø 15-150mm.

2/ Non magnetic steel

grade :Meet the P550 P530 standard

Steel

Non magnetic drill collar (or Flex), Crossover

Inch size 3 1/2”, 4 1/8” , 4 3/4 “, 5” ,6 1/2”, 6 3/4”, 7” , 8”9” etc.

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for Factory Supply Solid High Speed Tooling - Directional Powder HSS – Herui, The product will supply to all over the world, such as: Mauritania, Lisbon, San Diego, With the superior and exceptional service, we've been well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.

-

100% Original Factory N08810 - Elgiloy alloy (...

-

Low price Inconel Mig Wire - Elgiloy alloy (Co...

-

Factory For Non Magnetic Steel Case Ammo - HeR...

-

Ordinary Discount Capillary Cutter - Elgiloy a...

-

2021 China New Design M2 Hss - Elgiloy alloy (...

-

Cheapest Price Least Magnetic Stainless Steel -...