Good Quality Non-Magnetic Austenitic Stainless Steel - k/ Hot rolling large flat bar – Herui Detail:

ABOUT US

ZHENJIANG HERUI BUSINESS BRIDGE IMP&EXP Co., Ltd. Located in Danyang city, Jiangsu province of china. It’s a dynamic area for special steel and hardware tools. Relying on a network of qualified partners all specialized in metallic material . Offering a reliable short lead-time service. it’s a leading manufacturer and supplier of high speed steel and drill bits( saw blade), mould and die steel , non-magnetic steel and drill tools for oil field etc. We can supply in forms of wire, strip, plate, sheet, rod bar, tube and pipe at competitive prices to meet our customers′ requirements. Our Products can be widely used in petrochemical industry, aviation & aerospace, metallurgy, machinery, electronics, energy and so on. Our company possesses a fully integrated production process, it starts from vacuum melting or EAF+LF +VD +ESR to final packaging by the quality control and R&D teams, ensures all products meet the standards strictly.

1、Introduction to high-speed steel(HSS):

High-speed steel is a kind of high alloy special steel, the main alloy content of tungsten, molybdenum, chromium, vanadium, cobalt and other precious metals, it through the special heat treatment process, high temperature quenching and high temperature tempering, It can make the workpiece hardness reach HRC 63-70. It is used to make tools to cut other metal materials.High-speed steel has high hot hardness, high toughness , high wear resistance and other characteristics, so it used in the industrial area widely. Usually it used to make drills, miller, taps, HSS white knife, saws and other cutting tools.

2、Different grade chemical composition

HSS Chinese standard (GBT/9943-2008)

W4

| % | C | Mn | Si | S | P | Cr | V | W | Mo | Co |

| MIN | 0.83 | 0.20 | 0.70 | 3.80 | 1.20 | 3.50 | 2.50 | |||

| MAX | 0.93 | 0.40 | 1.00 | 0.030 | 0.030 | 4.40 | 1.80 | 4.50 | 3.50 |

M2

| % | C | Mn | Si | S | P | Cr | V | W | Mo | Co |

| MIN | 0.80 | 0.15 | 0.20 | 3.80 | 1.75 | 5.50 | 4.50 | |||

| MAX | 0.90 | 0.40 | 0.45 | 0.030 | 0.030 | 4.40 | 2.20 | 6.75 | 5.50 |

W9

| % | C | Mn | Si | S | P | Cr | V | W | Mo | Co |

| MIN | 0.77 | 0.20 | 0.20 | 3.80 | 1.30 | 8.50 | 2.70 | |||

| MAX | 0.87 | 0.40 | 0.40 | 0.030 | 0.030 | 4.40 | 1.70 | 9.50 | 3.30 |

T1

| % | C | Mn | Si | S | P | Cr | V | W | Mo | Co |

| MIN | 0.73 | 0.10 | 0.20 | 3.80 | 1.00 | 17.20 | ||||

| MAX | 0.83 | 0.40 | 0.40 | 0.030 | 0.030 | 4.50 | 1.20 | 18.70 |

M35

| % | C | Mn | Si | S | P | Cr | V | W | Mo | Co |

| MIN | 0.87 | 0.15 | 0.20 | 3.80 | 1.70 | 5.90 | 4.70 | 4.50 | ||

| MAX | 0.95 | 0.40 | 0.45 | 0.030 | 0.030 | 4.50 | 2.10 | 6.70 | 5.20 | 5.00 |

M42

| % | C | Mn | Si | S | P | Cr | V | W | Mo | Co |

| MIN | 1.05 | 0.15 | 0.15 | 3.50 | 0.95 | 1.15 | 9.00 | 7.75 | ||

| MAX | 1.15 | 0.40 | 0.65 | 0.030 | 0.030 | 4.25 | 1.35 | 1.85 | 10.0 | 8.75 |

3、Products

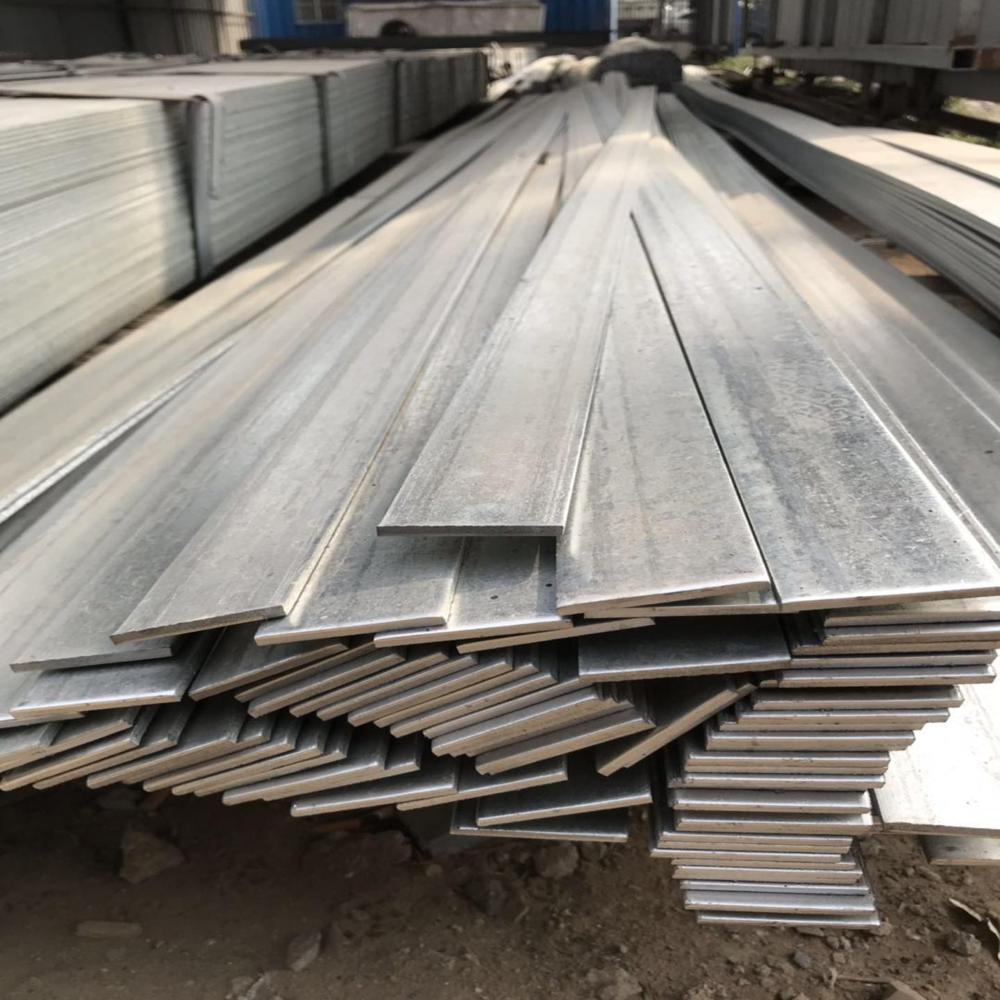

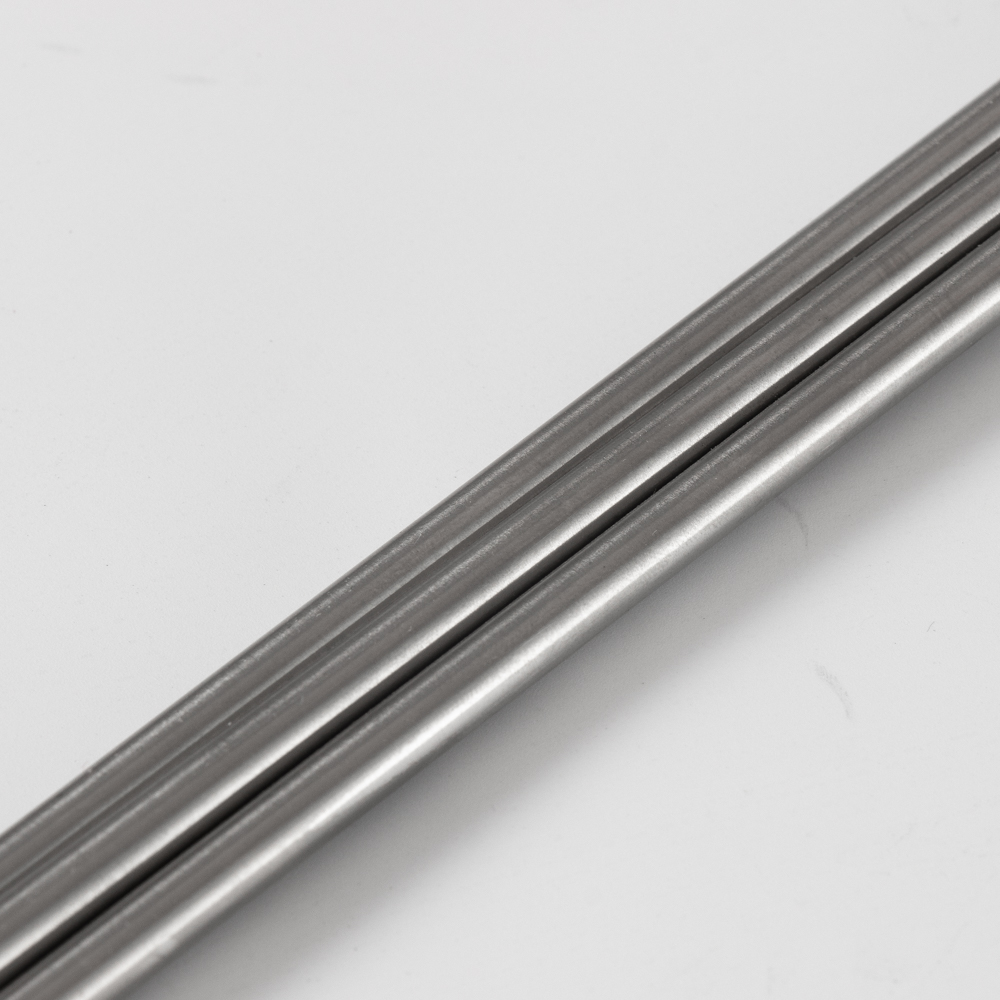

B/ Hot rolling large flat bar

thickness 10-40mm , width 300-800mm length 1500-3000mm

Product detail pictures:

Related Product Guide:

With a complete scientific quality management system, good quality and good faith, we win good reputation and occupied this field for Good Quality Non-Magnetic Austenitic Stainless Steel - k/ Hot rolling large flat bar – Herui, The product will supply to all over the world, such as: Atlanta, Tunisia, Curacao, we are sincerely hope to establish one good long term business relationship with your esteemed company thought this opportunity, based on equal, mutual beneficial and win win business from now till the future.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!