High definition Incoloy 801 - ERNiCrMo-3 – Herui Detail:

Keywords:

Inconel 625, AWS A5.14, EN18274, ASME II, SFA-5.14, EN/RN625, Nickel Alloy Welding Wire

Chemical composition

| Gr. No. | % | Ni | Cr | Mo | Nb+N | Fe | Al | Ti | C | Mn | Si | Cu | P | S |

| Inco 625 | Min | Bal. | 20 | 8 | 3.15 | |||||||||

| Max | 23 | 10 | 4.15 | 5 | 0.4 | 0.4 | 0.1 | 0.5 | 0.5 | 0.5 | 0.015 | 0.015 |

Pysical properties

| Density | 8.4 g/cm³ |

| Melting Point | 1290-1350°C |

Inconel 625 Alloy minimum mechanical properties in the room temperature

| Tensile Strength | Yield Strength | Elongation | Brinell Hardness |

| Rm N/mm² | R P0. 2N/mm² | A 5 % | HB |

| 760 | 345 | 30 | ≤220 |

Application

ERNiCrMo-3 is used primarily for gas tungsten and gas metal arc and matching composition base metals. It is also used for welding Inconel 601 and Incoloy 800. It can be used to weld dissimilar metal combinations such as steel, stainless steel, Inconel and Incoloy alloys.

Arcos 625, AWS ERNiCrMo-3, Military EN/RN625

Applications:

Useful for various dissimilar joints involving nickel alloys, carbon steel, low alloy and stainless steels. Primarily used on alloys 625, 601, 802 and 9% nickel.

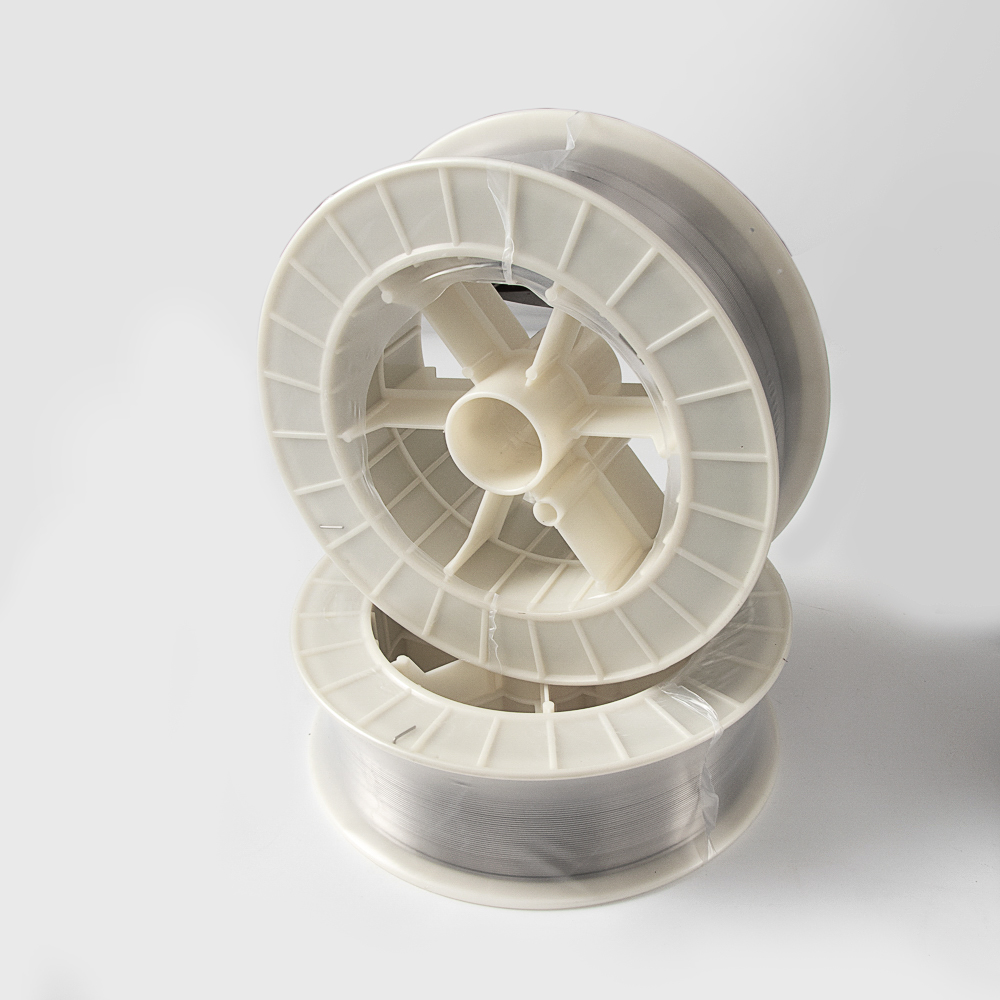

Product detail pictures:

Related Product Guide:

Normally customer-oriented, and it's our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for High definition Incoloy 801 - ERNiCrMo-3 – Herui, The product will supply to all over the world, such as: Somalia, Bangladesh, Cape Town, With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we're trying our best to be your good partner.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!