OEM/ODM Manufacturer 304 Stainless Magnetic - Non-magnetic flex drill collars – Herui Detail:

Non-magnetic flex drill collars are mainly used in horizontal directional drilling systems for tunnels in petroleum coal mines. Compared with Non-magnetic flex drill collars which is made of beryllium copper, the advantages of special alloy Non-magnetic flex drill collars are as follows:

(1) Non-magnetic: It has the characteristics of non-magnetic. Under the condition of 20 Oersteds, its permeability is 1.00005-1.0001 H/m, and it will not be magnetized in a strong magnetic field;

(2) Low density: The density is 4.5×103 kg/m3, which is 98% lower than that of beryllium copper;

(3) Low modulus of elasticity: The modulus of elasticity of beryllium copper is 1.35×105 MPa, while the modulus of elasticity of this alloy is 1.17×105 MPa, which is 1.15 times that of this alloy;

(4) High strength-to-mass ratio: the yield strength of this alloy is 840MPa, and its strength-to-mass ratio is 1.8 times that of beryllium copper;

(5) Good plasticity: the elongation at break is 2 to 5 times that of beryllium copper, which can reach the level of 120 steel grade;

(6) Corrosion resistance: It has anti-corrosion resistance and adaptability to the downhole environment. It can work in the acidic and highly corrosive environment of hydrogen sulfide, and its corrosion resistance is better than that of beryllium copper;

(7) Corrosion fatigue resistance: this alloy will not cause corrosion fatigue, its fatigue performance in the drilling fluid environment is the same as in the air, and its corrosion fatigue resistance is better than that of beryllium copper.

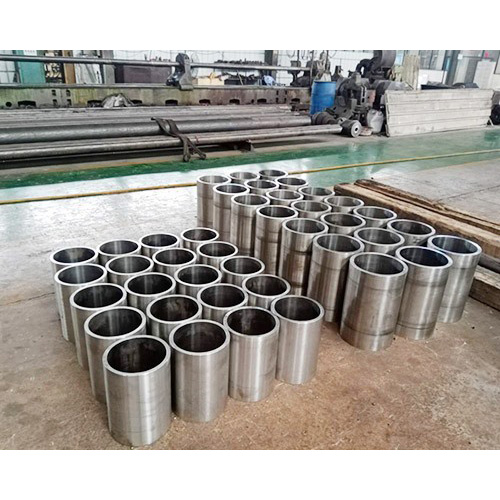

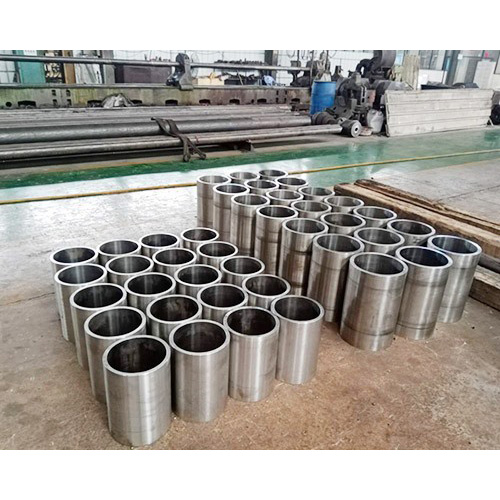

Product detail pictures:

Related Product Guide:

Our firm promises all consumers with the first-class products as well as most satisfying post-sale services. We warmly welcome our regular and new consumers to join us for OEM/ODM Manufacturer 304 Stainless Magnetic - Non-magnetic flex drill collars – Herui, The product will supply to all over the world, such as: Lebanon, Provence, Qatar, We aim to become the modern enterprise with the commercial ideal of "Sincerity and confidence" and with the aim of "Offering customers the most sincere services and best quality products". We sincerely ask for your unchanged support and appreciate your kind advice and guidance.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

-

Cheap PriceList for Least Magnetic Stainless St...

-

Lowest Price for Molybdenum High Speed Steel -...

-

Wholesale Dealers of High Speed Steel - Non-ma...

-

2021 wholesale price Hss 1.3343 - Inconel 625 ...

-

Hot Sale for Good Stainless Steel Non Magnetic ...

-

100% Original Factory Miranda High Speed Steel ...