Original Factory N05500 - PERMENDUR 2V / PERMENDUR 49 (HIPERCO 50A) / 1J22 / VACOFLUX 50 – Herui Detail:

Description

An alloy of 49% Cobalt, and 2% Vanadium, balance Iron. This alloy exhibits the highest magnetic saturation of any commercial alloy and excels in applications where this attribute is needed. This alloy has higher mechanical strength than other soft magnetic alloys. Permendur 2V is an alloy created by mixing 48-50% cobalt with iron (up to 2% vanadium can be added), it has a high permeability at high flux densities with a very high saturation point, its magnetic transition temperature is 980 °С. Its name in Russian is пермендюр (49К2ФА).

Chemical Composition (%)

C≤0.04

P≤0.020

S≤0.020

Mn≤0.30

Si≤0.30

Ni≤0.50

Cu≤0.20

Co: 49.0~51.0

V: 0.80~1.80

Fe: Balance

Applications

Electrical generators, pole pieces for electromagnets, magnetic bearings and high magnetic flux devices and instruments.

Equal Grades

1J22(China), UNS R30005, Permendur, Supermendur

Forms of Hiperco50 available

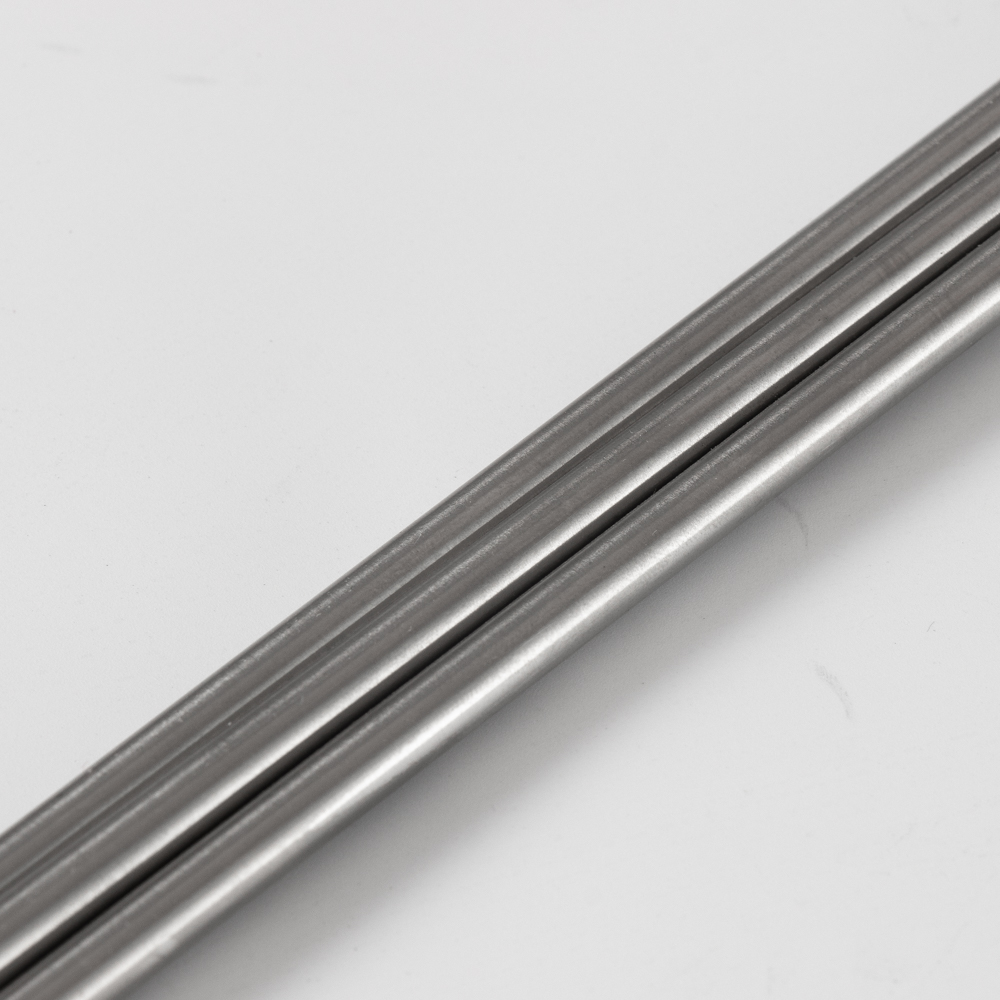

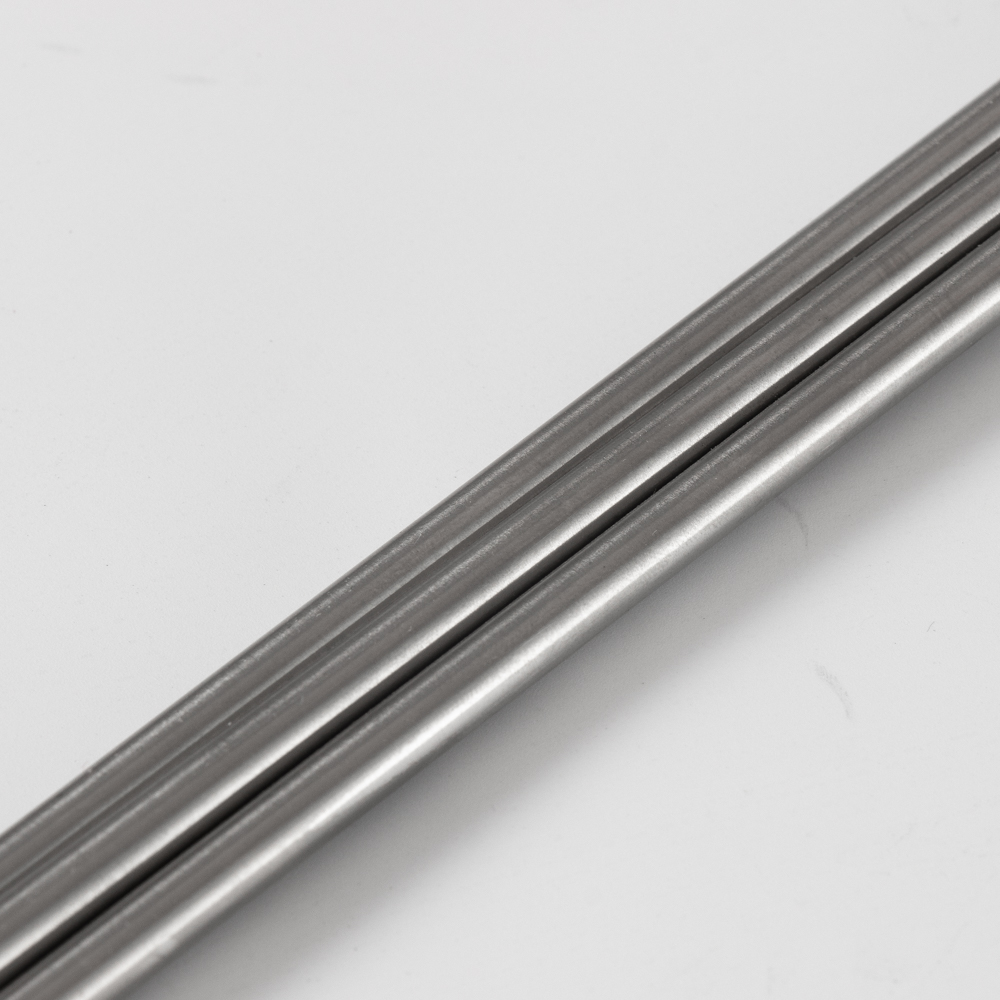

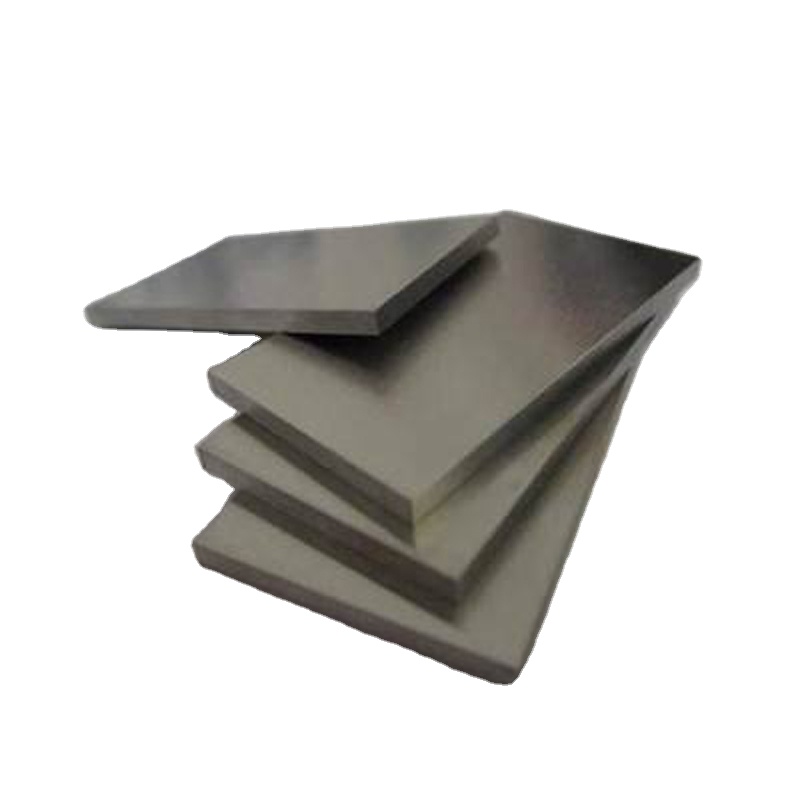

Forged bar, hot rolled bar, cold drawn bar, cold rolled strip

Product detail pictures:

Related Product Guide:

We can always satisfy our respected customers with our good quality, good price and good service due to we are more professional and more hard-working and do it in cost-effective way for Original Factory N05500 - PERMENDUR 2V / PERMENDUR 49 (HIPERCO 50A) / 1J22 / VACOFLUX 50 – Herui, The product will supply to all over the world, such as: Guatemala, Denmark, Swiss, With the development and enlargement of mass clients abroad, now we've set up cooperative relationships with many major brands. We've our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.

-

Super Purchasing for Non Magnetic Stainless Ste...

-

Factory wholesale High Speed Steel Material - ...

-

Lowest Price for Molybdenum High Speed Steel -...

-

Hot sale Factory A Capillary Tube - Inconel 71...

-

Bottom price 1.3343 Steel - Elgiloy alloy (Co4...

-

Special Price for How To Make Stainless Steel T...