Original Factory Nickel Alloy Bar - NILO Alloy 42 / W. Nr.1.3917 / UNS K94100 – Herui Detail:

Description

A nickel-iron controlled-expansion alloy containing 42% nickel. It has a low and nominally constant coefficient of thermal expansion from room temperature to about 570°F (300°C). Used for semiconductor lead frames in integrated circuits, bi-metal thermostat strip, thermostat rods, for ceramic-to-metal seals with alumina ceramics, and various glass-to-metal seals such as the core of copper-clad wire for sealing into glass envelopes of electric bulbs, radio valves, television tubes, and fluorescent lights.

FeNi42 (for example NILO alloy 42), has a nickel content of 42% and α ≈ 5.3 ppm/°C which matches that of silicon and therefore is widely used as lead frame material for electronic components, integrated circuits, etc.

Chemical Composition

| C | 0.05 |

| P | 0.020 |

| S | 0.020 |

| Mn | 0.80 |

| Si | 0.30 |

| Al | 0.10 |

| Co | 1.0 |

| Ni | 41.5~42.5 |

| Fe | Balance |

Average Coefficient of Linear Expansion ā/(10-6/K)

| 20~100℃ | 5.6 |

| 20~200℃ | 4.9 |

| 20~300℃ | 4.8 |

| 20~400℃ | 5.9 |

| 20~450℃ | 6.9 |

| 20~500℃ | 7.8 |

| 20~600℃ | 9.2 |

Applications

Alloy 42 has been used for the glass-to-metal seals in electronic tubes, automotive and industrial lamps, transformer and capacitor bushings and other glass-to-metal and ceramic-to-metal applications.

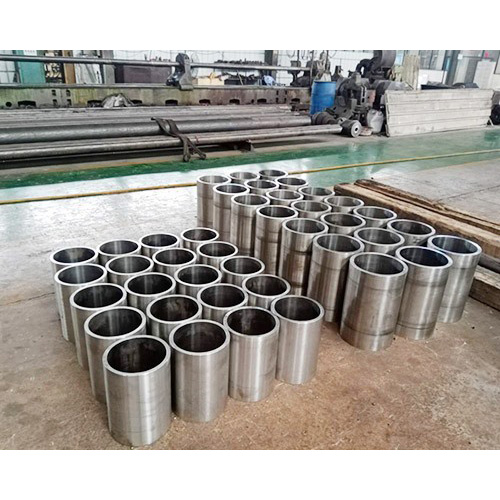

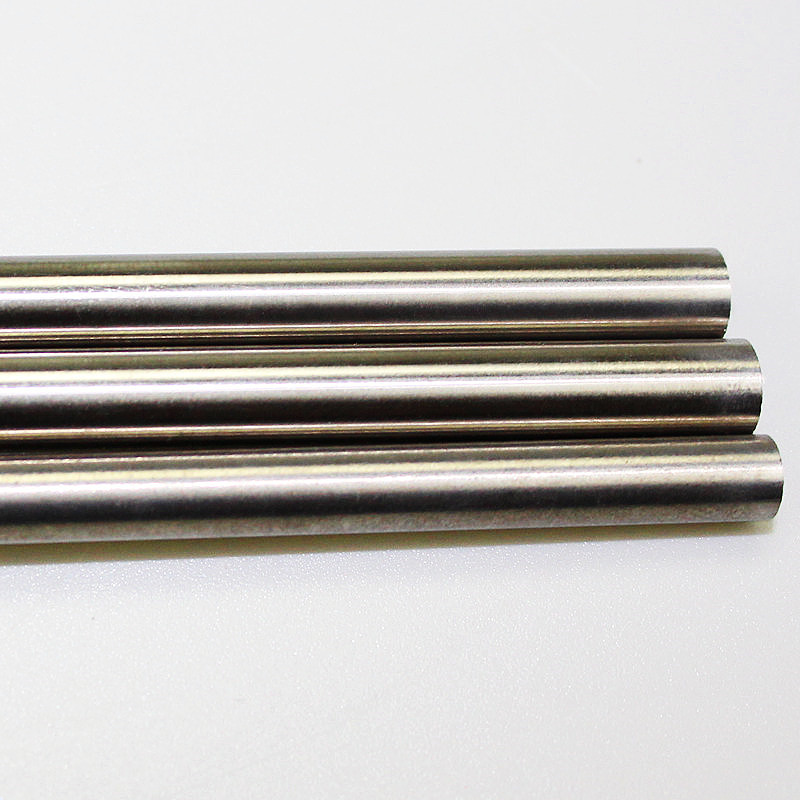

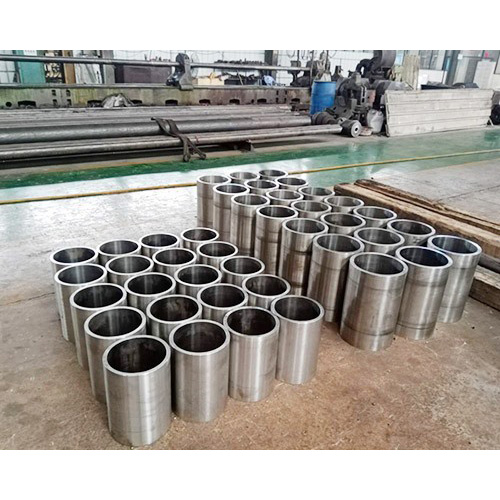

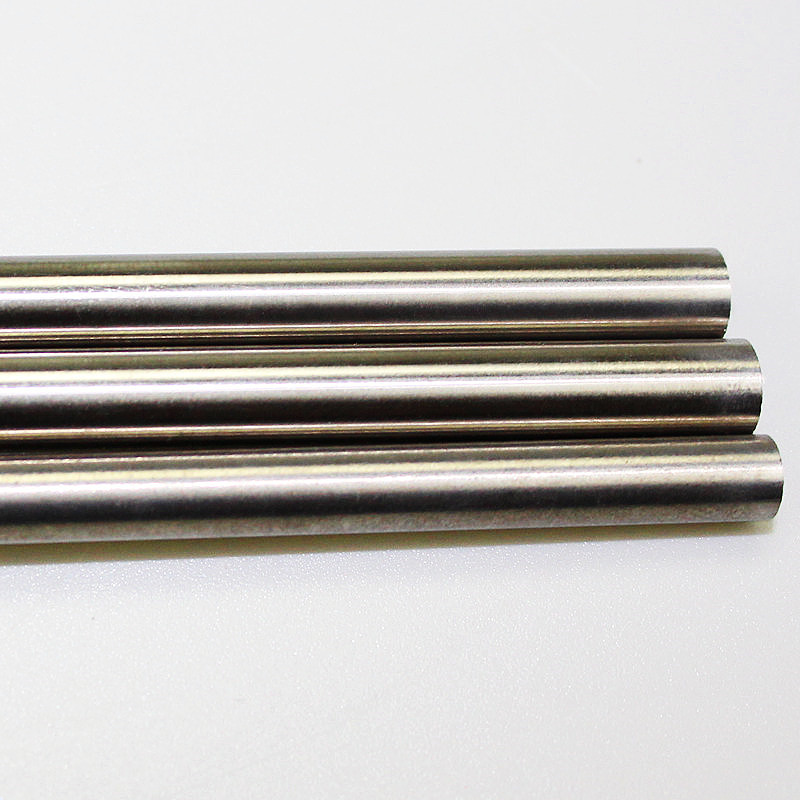

Forms

We can supply these products in all forms including wire, ribbon, strip, sheet and foil. You also can send your custom Dimensions and Tolerances by email or phone us.

Product detail pictures:

Related Product Guide:

We thinks what customers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better good quality, lower processing costs, prices are extra reasonable, won the new and old buyers the support and affirmation for Original Factory Nickel Alloy Bar - NILO Alloy 42 / W. Nr.1.3917 / UNS K94100 – Herui, The product will supply to all over the world, such as: South Korea, Colombia, Nepal, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

-

Reliable Supplier Non Magnetic Stainless Steel ...

-

Special Design for Incoloy 903 - Elgiloy alloy...

-

2021 Good Quality German Silver Wire - Made In...

-

Best-Selling Monel Monaco - Elgiloy alloy (Co4...

-

Free sample for Non Oriented Silicon Steel - A...

-

2021 Good Quality German Silver Wire - High qu...