Personlized Products Uns 4400 - Hot-selling Non-magnetic Steel, High Quality Non-Magnetic Drill Collars – Herui Detail:

- Place of Origin:

-

Jiangsu, China

- Brand Name:

-

HeRui

- Model Number:

-

NMDC HR-P530

- Application:

-

Oil Field

- Shape:

-

Pipe

- Material:

-

Mn-Cr-N steel

- Chemical Composition:

-

Mn: 16.00-19.00, Cr: 15.00-17.00

- Standard:

-

API Spec. 7.1

- Appearance:

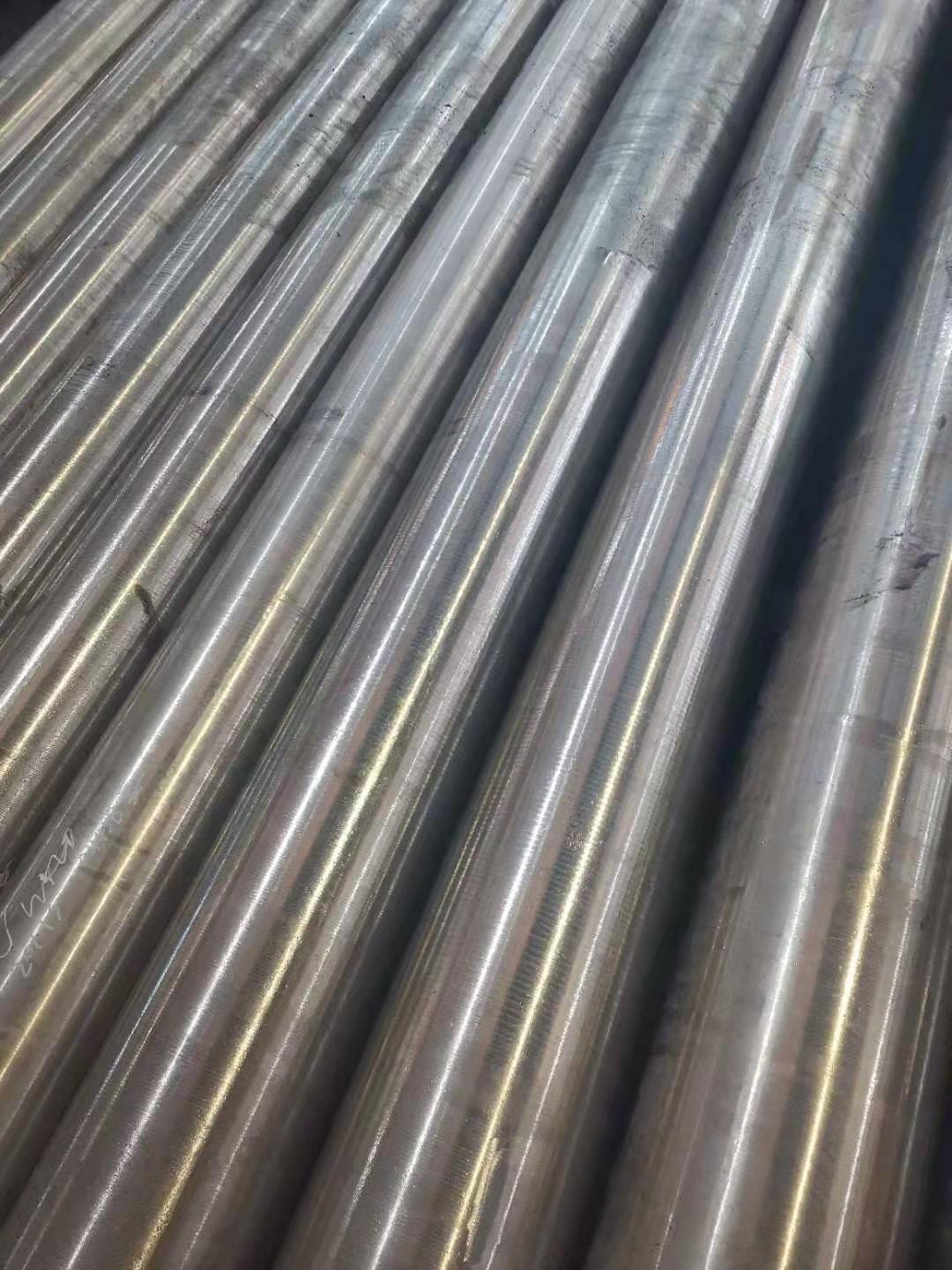

-

Bright

- Delivery time:

-

15-20 Days

- Screw Type:

-

NC, REG, IF, FH

- Size:

-

Customized

1. CHEMICAL COMPOSITION

“P530” is a special nonmagnetic, austenitic Mn-Cr-N steel with a Nickel-content of ≤2%.

C: 0,05max, Mn: 18.50-20.00, Cr: 13.00-14.00, Mo: 0.40-0.60, N: 0.25-0.40, Ni: 2.00max.

2. MECHANICAL PROPERTIES

Following mechanical properties (tested at room temperature) are achieved by a special cold-working process over the full length of the collar:

Yield Strength (min.): OD less than 4”830 N/mm²

0,2%-offset method: OD 4”to 9 1/4”/ 760 N/mm²

OD 9 1/2”and larger / 690 N/mm²

Tensile Strength: OD less than 4”/ 900 N/mm²

OD 4”and larger / 830 N/mm²

Elongation (min.): 25%

Reduction of area (min.): 50%

Impact energy (min.): 122 J

Hardness Brinell (min.): 285-350 HB

3. MAGNETIC PROPERTIES

Relative permeability: ≤1,001.

4. CORROSION RESISTANCE

- Transgranular SCC: Prevented by special surface treatments (Hammer peening, roller burnishing, shot peening).

- Intergranular SCC: The occurrence of material sensitization is prevented by quenching after warm-forging. Each collar is tested according to ASTM A 262, Pract. A and E, last edition

5. NON-DESTRUCTIVE TESTING

- Magnetic inspection: Drill collars are 100% tested by a proprietary probe-testing process using a Förster Magnetomat 1.782. (“Hot Spot”-test). Magnetic permeability of each collar is certified with the printout of probe-testing.

- Ultrasonic inspection: Each collar is ultrasonically inspected over 100% of the volume according to ASTM E 114, last edition as a minimum level.

6. GALLING RESISTANCE

“P530” is due to the chemical composition and the special cold-working process less susceptible to galling than Cr-Ni steels.

Non-Magnetic material optimized for MWD-collars and stabilizers (higher strength and endurance) is available on special request. P530-Non-Magnetic Drill Collars meet all requirements of API Spec. 7.1, last edition. All tests are carried out according to ASTM-Standards, last editions.

ZHENJIANG HERUI BUSINESS BRIDGE IMP&EXP Co., Ltd is a leading manufacturer and supplier of high speed steel, non-magnetic steel, nickel-based alloys, etc. we can supply in forms of wire, strip, sheet, rod, bar, tube and pipe at competitive prices to meet our customers’ requirements. Our Products can be widely used in petrochemical industry, aviation & aerospace, metallurgy, machinery, electronics, energy and so on. Our company possesses a fully integrated production process, it starts from vacuum melting to final packaging led by the quality control and R&D teams, ensures all products meet the standards strictly. We always can serve the reliable products with on-time delivery. “quality first, customer foremost “, Zhenjiang Herui Business Bridge IMP & EXP Co., Ltd welcomes you to visit our company sincerely and be dedicated to supplying you our quality products with the best service.

Product Category

High speed steel

Non-magnetic steel

Mold / Die steel

High-temperature alloys

Corrosion-resistance alloys

Precision alloys

Pure nickel

Welding wire

Thermal spraying wire

Capillary tube

Q: Are you trading company or manufacturer?

A: We are a manufacturer with our own import and export company.

Q: How long is your delivery time?

A: Generally speaking, 20 days according to the quantity.

Q: Do you provide samples?

A: Yes, we could provide the sample free of charge.

Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, the balance before shipment.

Q: How can I place order?

A: You can contact us by email, or place orders online.

Q: How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T, L/C, Western Union are the most usual ways we are using. If you want to use other way, please tell me, we can discuss it.

Q: What’s the order procedure?

A: First we discuss order details, production details by email or TM. Then we issue you an PI for your confirmation. You will be requested to do prepaid full payment or deposit before we go into production. After we get the deposit, we start to process the order. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

Q: How do you take care when your clients received defective products?

A: replacement. If there are some defective items, we usually credit to our customer or replace in next shipment.

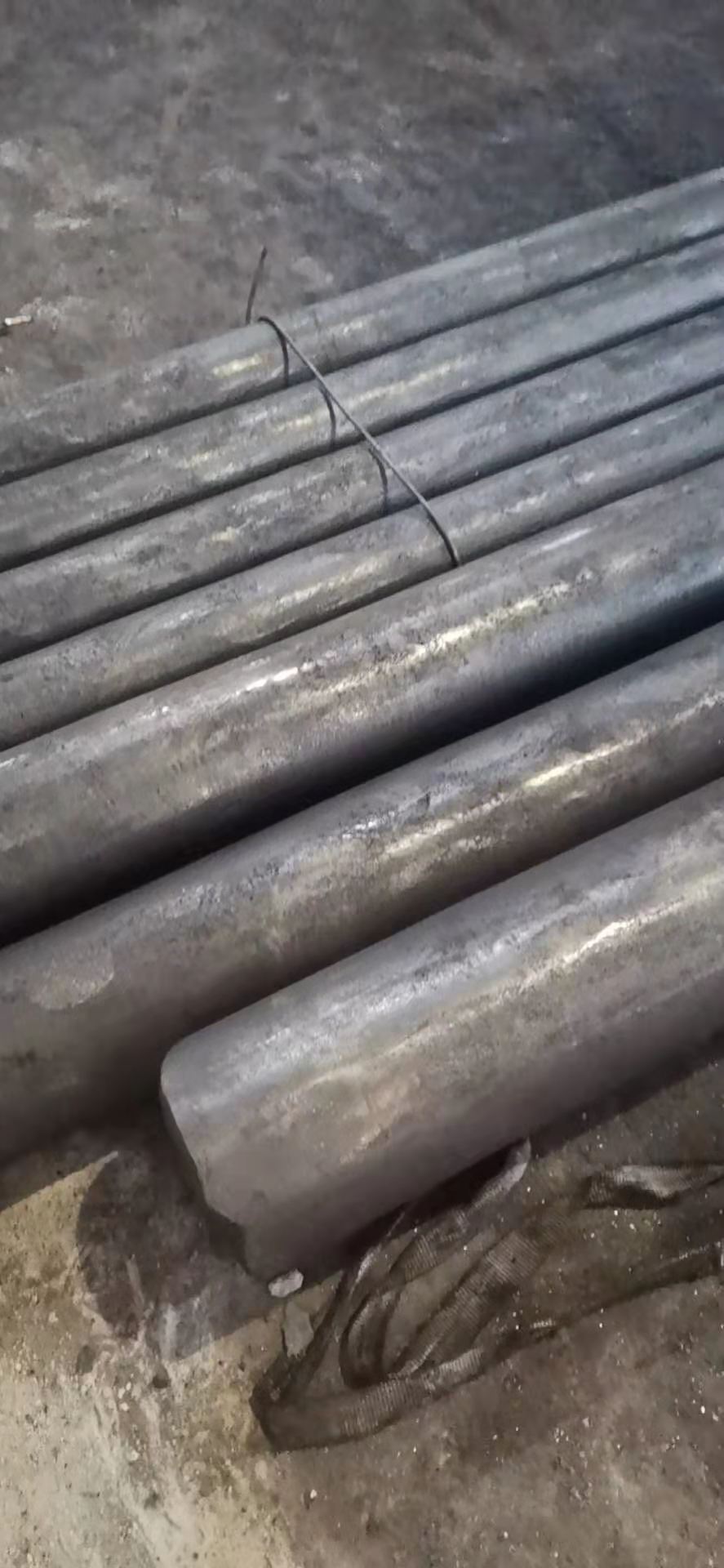

Product detail pictures:

Related Product Guide:

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for Personlized Products Uns 4400 - Hot-selling Non-magnetic Steel, High Quality Non-Magnetic Drill Collars – Herui, The product will supply to all over the world, such as: UK, Cyprus, Afghanistan, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.

-

Renewable Design for High Speed Steel M2 - Non...

-

Cheapest Factory High Speed Steel Router Bits -...

-

Chinese Professional High Speed Steel Rod - No...

-

Wholesale Nickel Series - Elgiloy alloy (Co40C...

-

Super Lowest Price Non Oriented Silicon Steel -...

-

Wholesale Discount Incoloy 840 - Elgiloy alloy...