PriceList for High Speed Steel Cutting Tools - ERNiCrMo-4 / specified nickel-based welding wire for C-276 – Herui Detail:

Standard

AWS 5.14 ERNiCrMo-4

Features

C-276 welding wire / ERNiCrMo-4 is mainly used for tungsten-inert gas welding (TIG) and melting gas welding with C276 alloy and other nickel-chrome-molybdenum alloy; it can also be used for surface welding of steel; this welding material has shown excellent corrosion resistance in a variety of corrosive media, especially resistant to pitting and crack corrosion.

ERNiCrMo-4 wire can be used for welding heterogeneous materials, including C276 with other nickel alloys, stainless steels and low-alloy steels.

Typical value of deposited metal composition (%)

| Type | Chemical composition of code | Chemical composition.% | ||||||||

| C | Mn | Fe | Si | Cu | Ni | Cr | Mo | W | ||

| SNi6276 | NiCr15Mo16Fe6W4 | ≤0.02 | ≤1.0 | 4.0-7.0 | ≤0.08 | ≤0.5 | ≥50.0 | 14.5-16.5 | 15.0-17.0 | 3.0-4.5 |

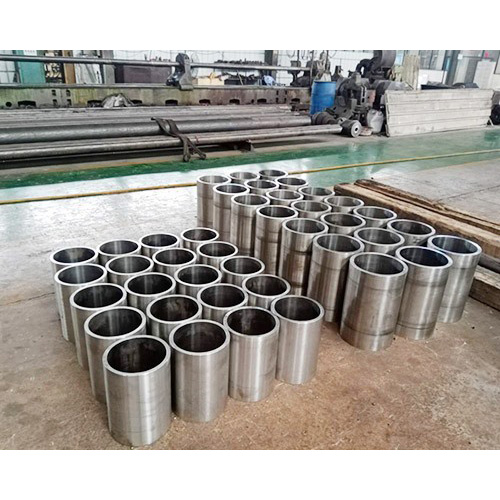

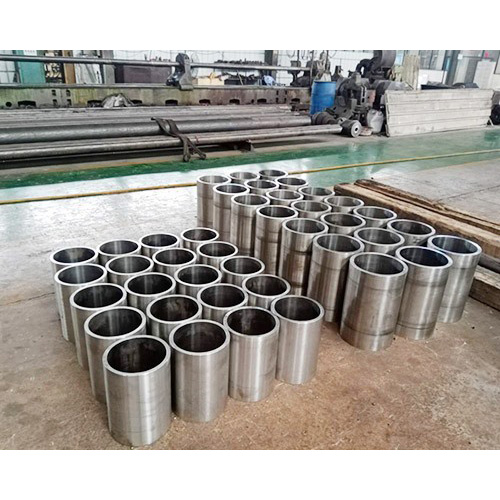

Product detail pictures:

Related Product Guide:

We offer great strength in quality and development,merchandising,sales and marketing and operation for PriceList for High Speed Steel Cutting Tools - ERNiCrMo-4 / specified nickel-based welding wire for C-276 – Herui, The product will supply to all over the world, such as: Ecuador, Somalia, Istanbul, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

-

Hot sale Epoc Capillary Tubes - Factory price ...

-

2021 Latest Design M35 Flat Steel - Elgiloy al...

-

8 Year Exporter High Speed Carbon Steel - Non-...

-

Reasonable price Tensile Strength Of Non Magnet...

-

PriceList for Hss Round Bar - Elgiloy alloy (C...

-

2021 New Style Nickel Strip Tape - High Precis...