Special Design for Most Non Magnetic Stainless Steel - Soft Magnetic Alloy 1J85 – Herui Detail:

Description

1J85 is a kind of Fe-Ni soft magnetic alloy with high weak magnetic field permeability. It has high permeability and low coercivity in weak magnetic field. Widely used in radio electronics industry, precision instruments and meters, remote control and automatic control systems.

Chemical Composition

| C | P | S | Cu | Mn | Si | Mo | Ni | Fe |

| (≤) | ||||||||

| 0.03 | 0.020 | 0.020 | 0.20 | 0.30-0.60 | 0.15-0.30 | 4.8-5.2 | 79.0-81.0 | Bal. |

Mechanical Properties

| Density (g/cm3) | Electrical Resistivity(μΩ•m) | Curie Point(℃) | Magnetic Properties (10-6 ) |

| 8.75 | 0.56 | 400 | 0.5 |

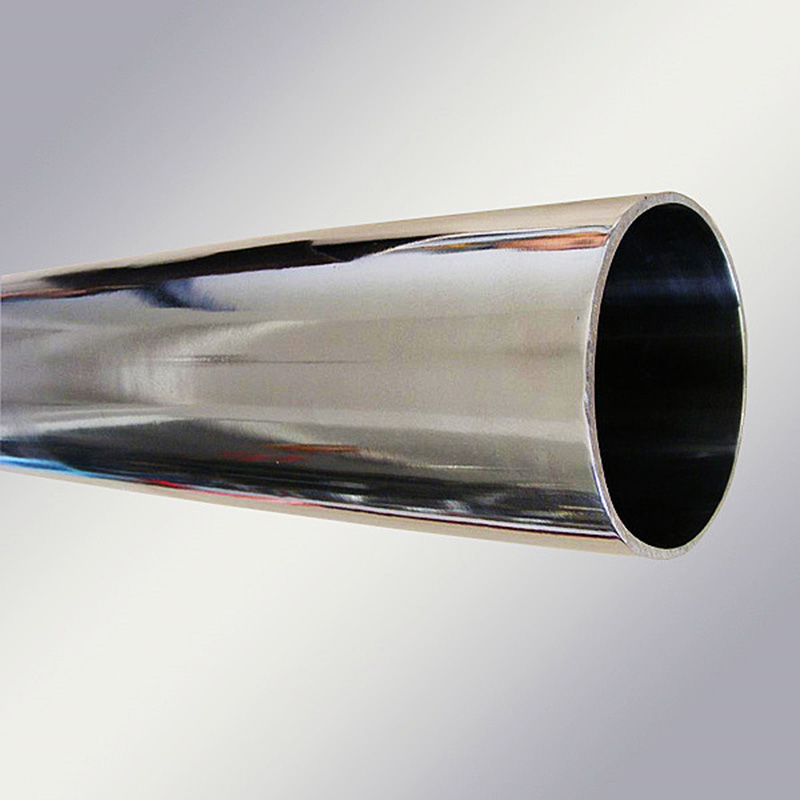

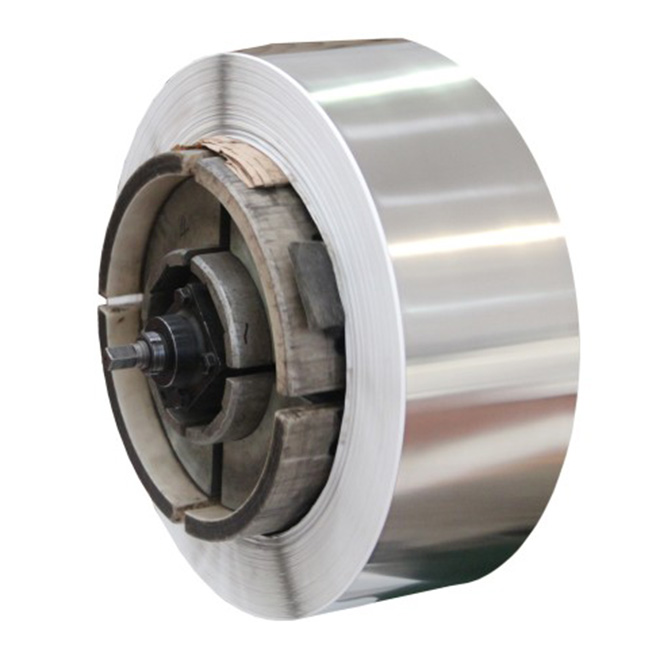

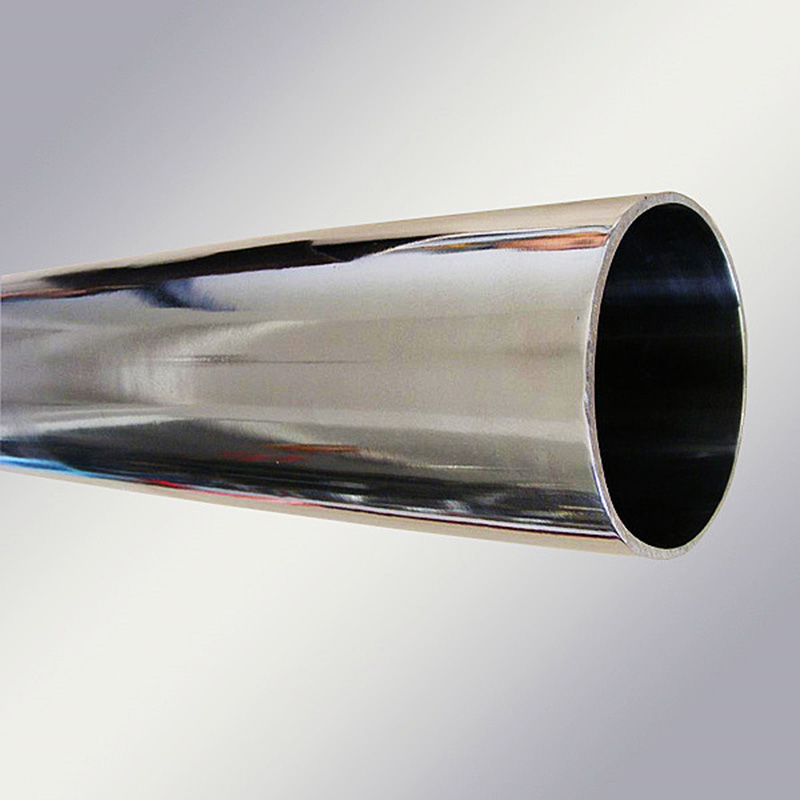

Form Available

bar, plate, strip

Product detail pictures:

Related Product Guide:

Dedicated to strict quality management and thoughtful client services, our experienced staff customers are generally available to discuss your demands and guarantee full client pleasure for Special Design for Most Non Magnetic Stainless Steel - Soft Magnetic Alloy 1J85 – Herui, The product will supply to all over the world, such as: azerbaijan, Canada, Palestine, We look forward to hearing from you, whether you are a returning customer or a new one. We hope you will find what you are looking for here, if not, please contact us immediately. We pride ourselves on top notch customer service and response. Thank you for your business and support!

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.

-

Bottom price Alloy 718 Round Bar - Elgiloy all...

-

Leading Manufacturer for Incoloy Ds - Electric...

-

China OEM Skh51 Steel - Elgiloy alloy (Co40CrN...

-

professional factory for Twist Bit High Speed -...

-

Factory Cheap Capillary Collection Tubes - Api...

-

China New Product Nickel Chrome Wire - Incoloy...