18 Years Factory Hss Coiled Material - Api Standard High Quality Non-magnetic Spiral Drill Collar For Oil field – Herui Detail:

- Condition:

-

New

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- Local Service Location:

-

None

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

New Product 2020

- Place of Origin:

-

Jiangsu, China

- Brand Name:

-

HR

- Type:

-

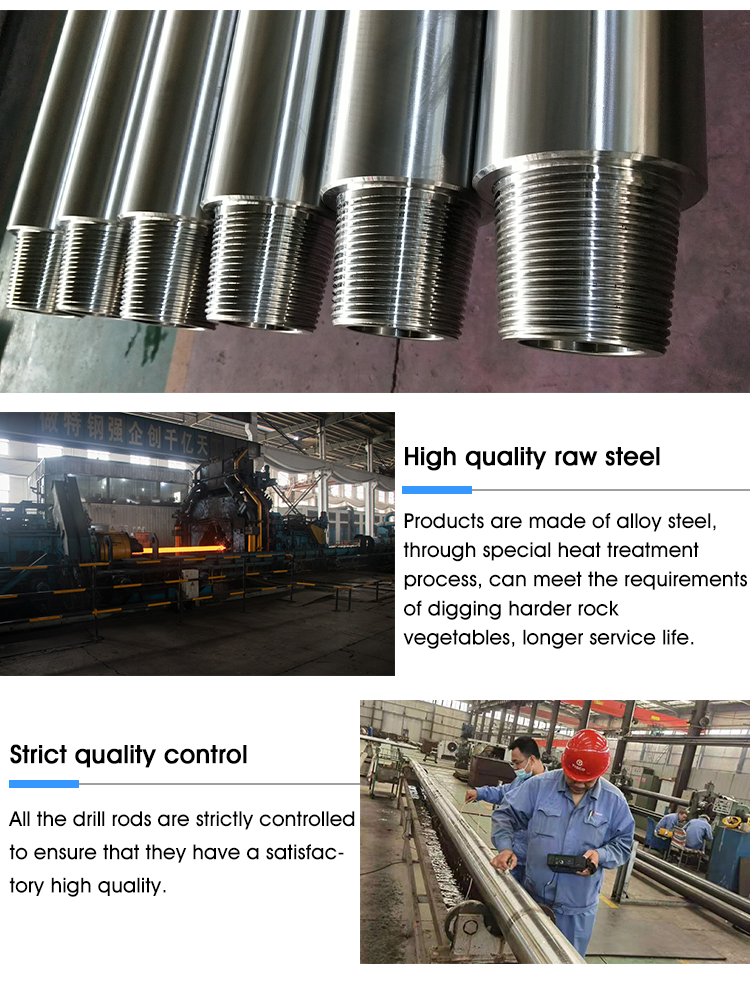

Drill Collar, Non magnetic steel

- Machine Type:

-

Drilling Equipment

- Certification:

-

API

- Use:

-

Well Drilling

- Product name:

-

Non-magnetic drill collar

- Usage:

-

oil exploitation

- Appearance:

-

Round column

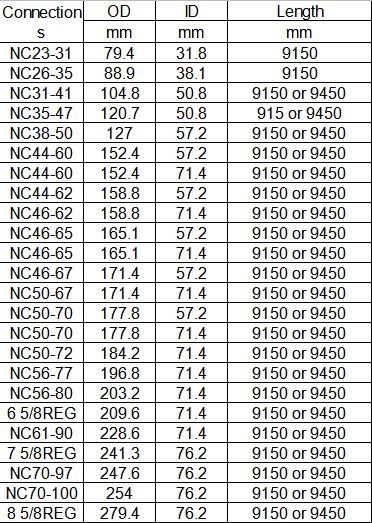

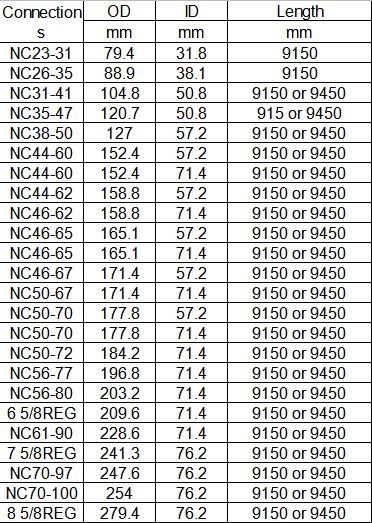

- Size:

-

3 1/2″, 4 1/8″ , 4 3/4 “, 5″ ,6 1/2″, 6 3/4″, 7″ , 8″ 9″ etc

- Standard:

-

API Spec 7-1

- Main Market:

-

Mn Cr Ni

- Advantage:

-

Quality. We have sales staff in Europe

- Package:

-

Plastic wrap

- Purity:

-

C Si Mn P S Cr Ni Mo Cu N

|

item

|

value

|

|

Product name

|

API p550 p530 non-magnetic drill collar

|

|

Minimum Order Quantity

|

50 kg

|

|

Port

|

SHANGHAI / NINGBO

|

|

Delivery Time

|

15 DAYS SINCE RECEIVING DEPOSIT

|

|

Payment Terms

|

T/T,Western Union,L/C,D/P

|

|

Service

|

24 hours service

|

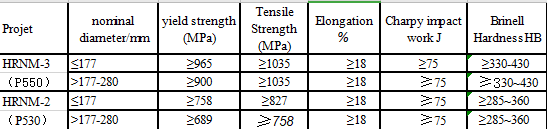

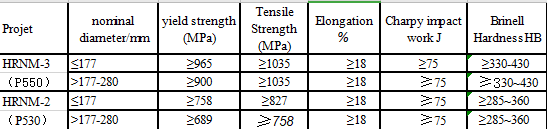

* Hrnm-2 is similar to P530 standard material

Hrnm-3 is similar to P550 standard material

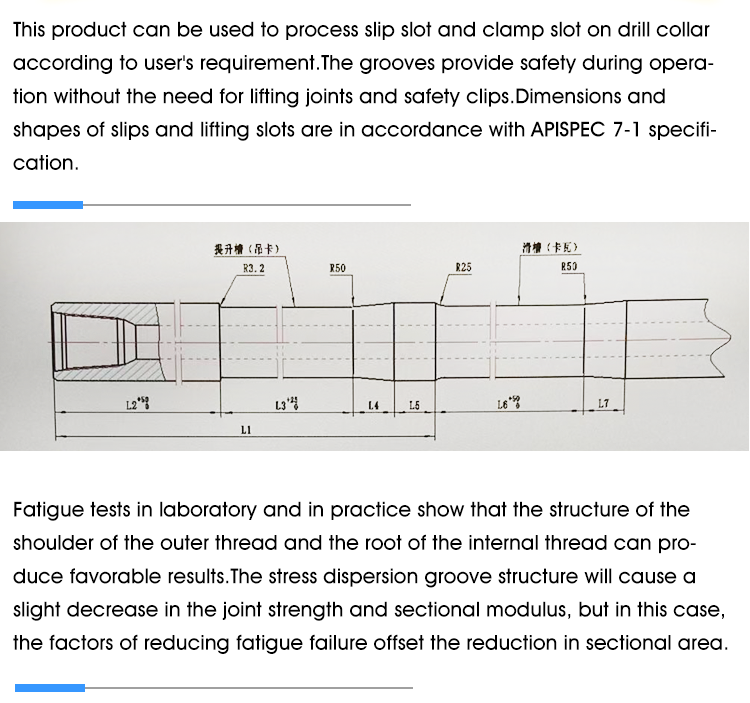

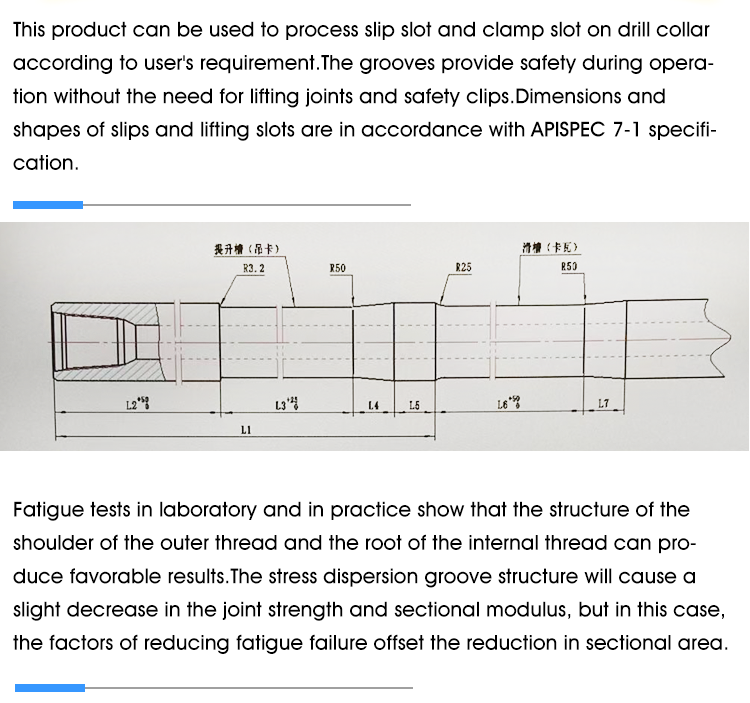

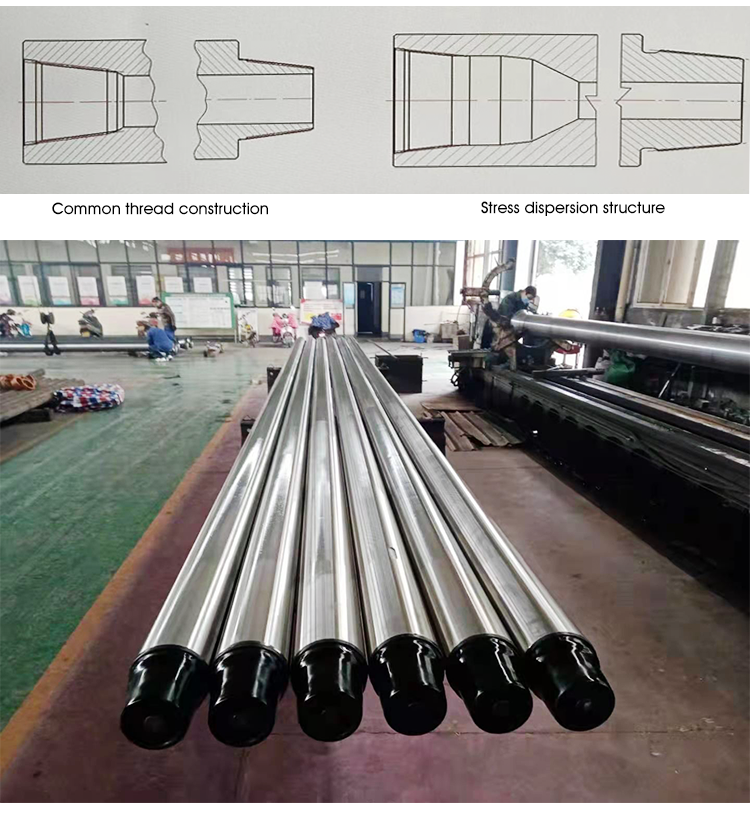

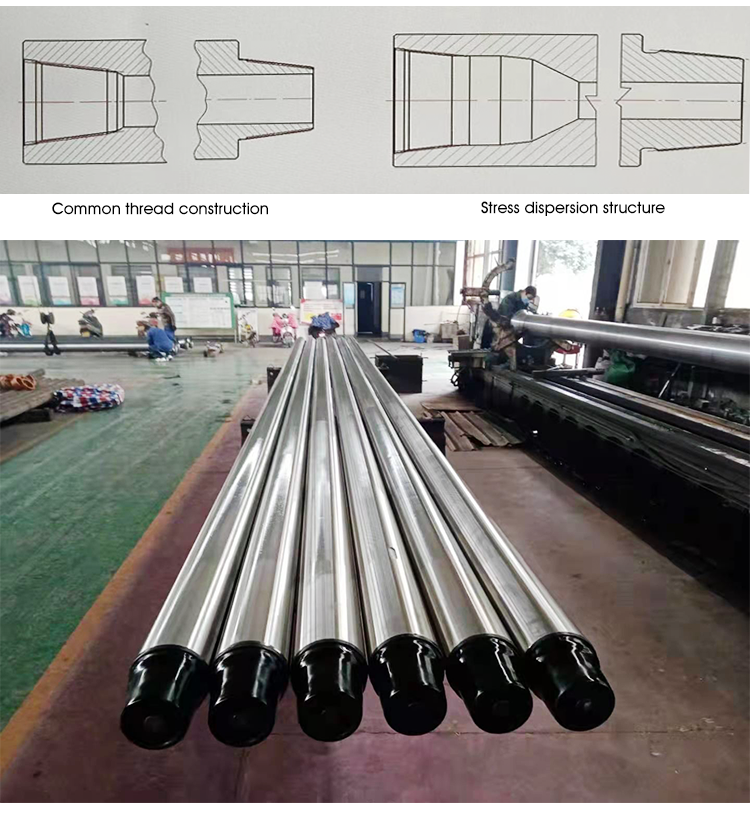

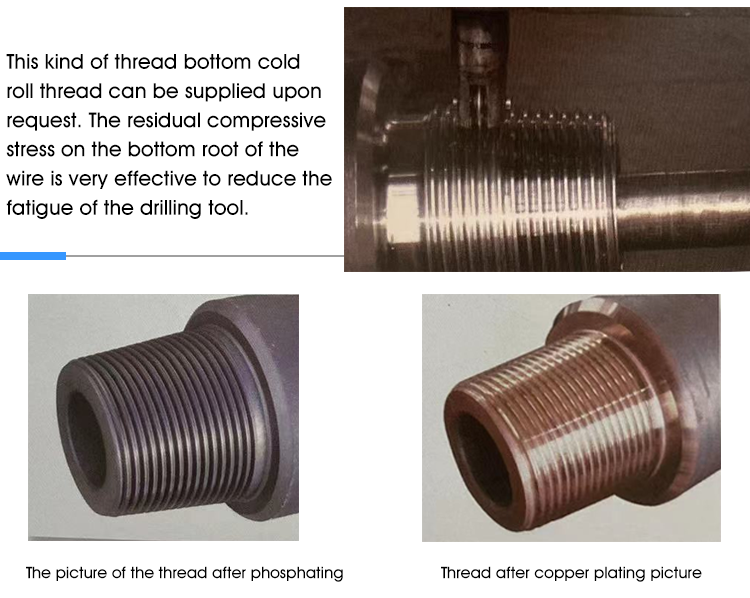

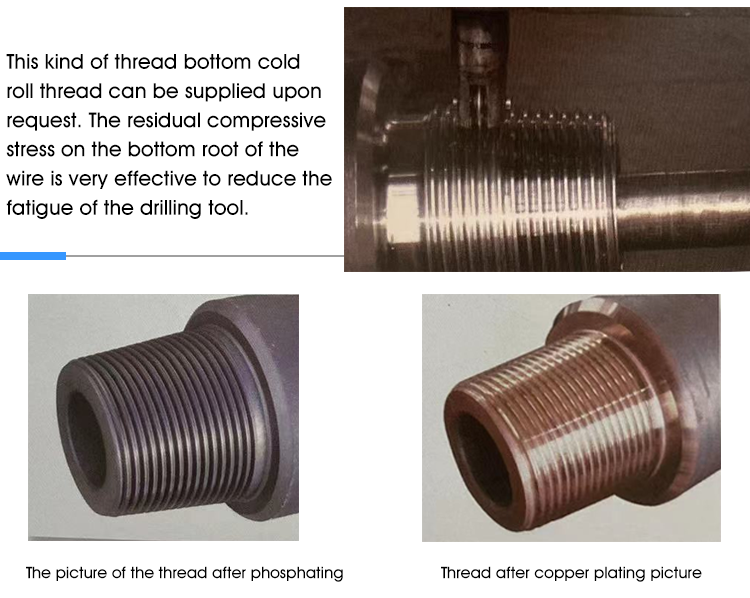

Product detail pictures:

Related Product Guide:

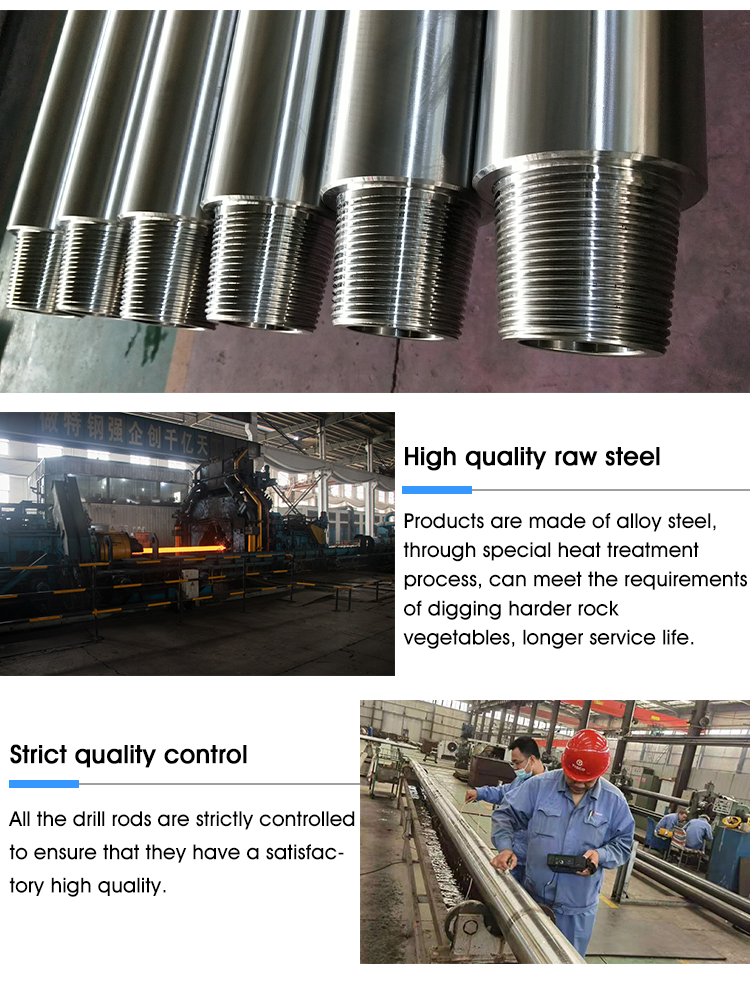

To fulfill the customers' over-expected fulfillment , we have now our solid staff to deliver our greatest general assistance which includes internet marketing, product sales, creating, manufacturing, excellent controlling, packing, warehousing and logistics for 18 Years Factory Hss Coiled Material - Api Standard High Quality Non-magnetic Spiral Drill Collar For Oil field – Herui, The product will supply to all over the world, such as: Wellington, Brunei, Tanzania, Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

-

2021 High quality N08811 - Inconel C-276 / Has...

-

Factory Cheap Hot Hss Steel Rod - No magnetic ...

-

New Delivery for Monel Alloy 400 - Elgiloy all...

-

Popular Design for Non Magnetic Stainless Steel...

-

Factory directly High Speed Steel Lathe Tools -...

-

China Cheap price Machining Monel 400 - Incone...