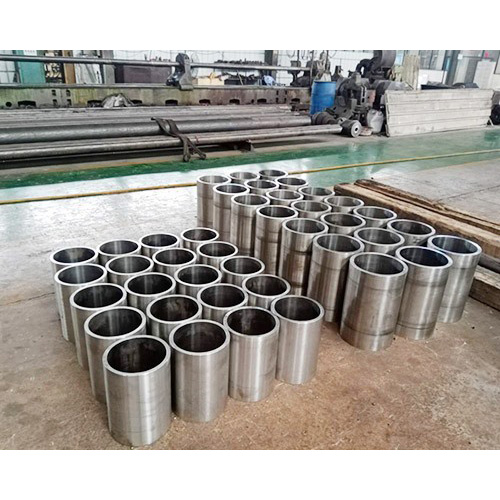

factory low price High Speed Steel Lathe Tool Bits - High speed steel M2 round bar – Herui Detail:

Video

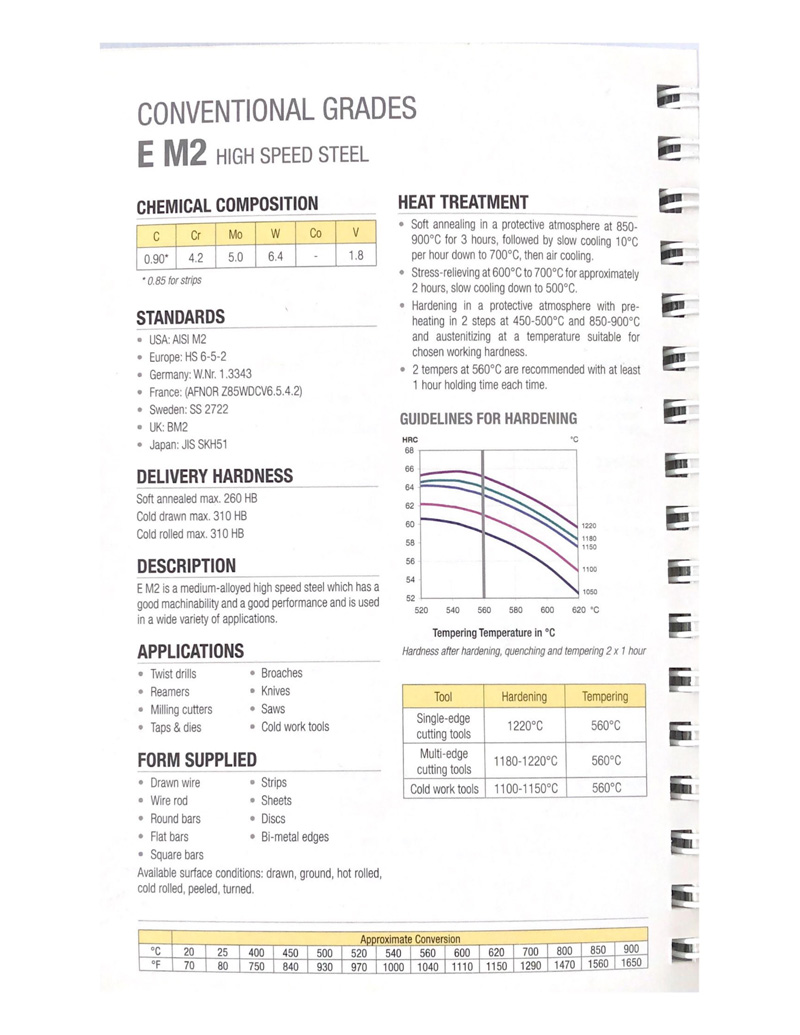

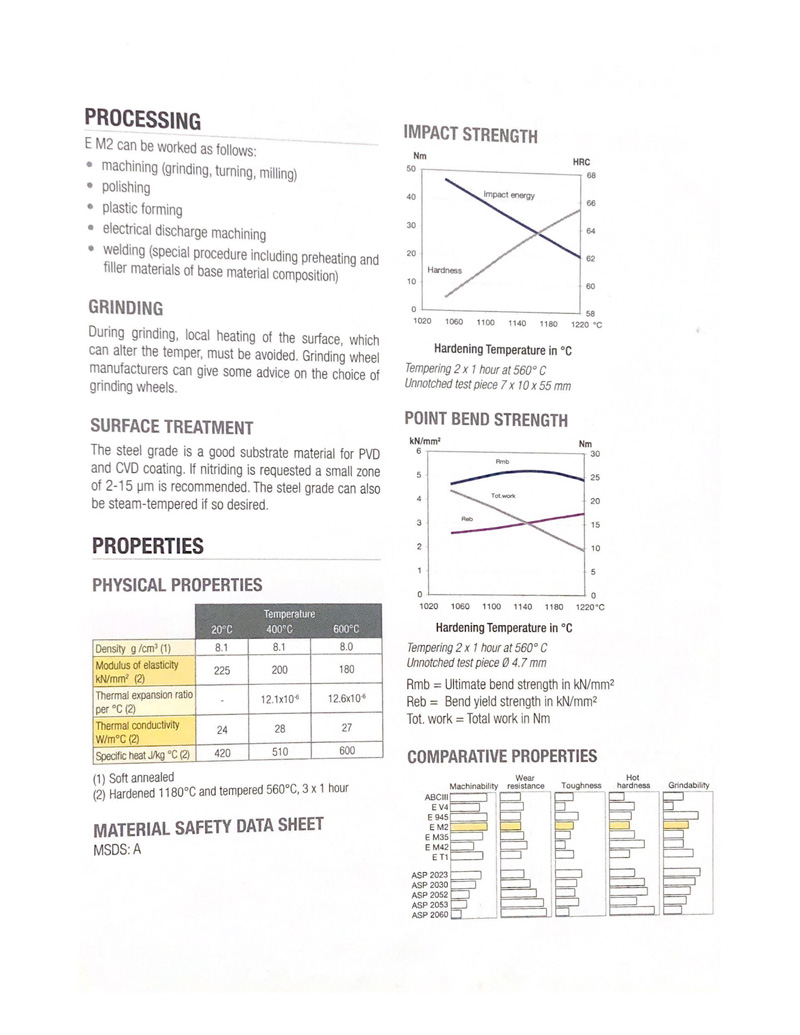

M2 round bar is a representative steel grade of tungsten-molybdenum general-purpose high-speed steel, toughness, wear resistance is better than W18Cr4V, hardness, red hardness and high temperature hardness is comparable. It can be used for the manufacture of various tools with high impact forces, large general tools and thermoplastic forming tools, as well as for wear parts under high loads and cold work moulds.

M2 is a molybdenum-based high-speed steel with the advantages of low carbide inhomogeneity and high toughness. It is easy to overheat, so the quenching heating temperature should be strictly controlled, and the heat treatment protection requirements are more stringent. Due to its hardness and good wear resistance, it is mostly used in the manufacture of cutting tools for difficult-to-cut materials. M2 HSS has a greater tendency to carbide, so the heat treatment protection requirements are more stringent, suitable for vibration and impact load bearing moulds.

Main applications:

Cold forging dies, fine blanking dies, powder pressing dies, etc., shearing machine dies, plastic dies with added glass fibre, etc. Dies suitable for vibration and impact loads: deep drawing dies, punching dies. Metal cutting saw blades, cold heading and extrusion tools, etc.

Description

Chemical composition

Carbon C: 0.80-0.90 (Allowable deviation: ±0.01)

Silicon Si: 0.20~0.45 (Allowable deviation: ±0.05)

Manganese Mn:0.15~0.40(Allowable deviation:+0.04)

Sulfur S: ≤0.030

Phosphorus P:≤0.030

Chromium Cr:3.80~4.40(Allowable deviation:±0.05)

Nickel Ni: residual content ≤0.30

Copper Cu: residual content ≤0.25

Vanadium V:1.75~2.20(Allowable deviation:±0.05)

Molybdenum Mo:4.50~5.50(Allowable deviation: size≤6,±0.05;size>6,±0.10)

Tungsten W :5.50~6.75(Allowable deviation: size≤10,±0.10;size>10,±0.20)

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for factory low price High Speed Steel Lathe Tool Bits - High speed steel M2 round bar – Herui, The product will supply to all over the world, such as: Mongolia, Australia, Benin, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

The use and maintain of the sawblade

◎ The carbide tip of sawblade is very sharp, so process of using must be prevent the carbide tip.

◎ PeriodicaI cleaning and support the machine,the spindle’s running tolerance must be less than h7.

◎ The flanges must be parallel to each other,must be of the same diameter 1/3 of the sawblade’s diameter(formuIti—rip saw blade is 1/2.

◎ When instaIIion the sawbIade,it shaII be 5-6 teeth higher than board surface.

◎ Before operation,check the firmly of the sawblade,be sure nobody in front of the machine. Do not feed of operation check whether the machine is good for operaiton. Periodical check the function of the machine,the certicaI jump is less than ±0.02MM,and the flap is less than ±0.01.

◎ After continuous use,must be removed and cleaning the sawblade,get rid of the resin and sawdust of the sawblade of both sides.Other wise it would beinfluence the effect of using the sawblade.

◎ Deposit of the sawblade,must not be layer the sawblade,it is putted in the originaI package inside.

The renovate of the sawbIade

◎ The renovate of the carbide sawblade While it no longer sharpen and the horizontaI piece coarseaess. The power of using sawblade machine obviously Increase. When process materiaI,the materiaI appearred burst. The carbide tip exhaust more than 0.02MM.

◎ For the renovate the sawblade,it shouId be grinding by the a formal company, so be sure the quality of the sawblade after renovating.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

-

Factory Price Tool Steel Supplier - Elgiloy al...

-

China New Product Non Magnetic Hardened Steel -...

-

Chinese wholesale M2 Steel - Elgiloy alloy (Co...

-

Factory Cheap Non Heparinized Tube - Elgiloy a...

-

2021 High quality M2 Tool Steel Supplier - Hig...

-

OEM manufacturer 316 Ss Magnetic - Non-magneti...